Cobotics integrates collaborative robots that work alongside human operators to enhance flexibility and efficiency in manufacturing processes. CNC machining relies on computer-controlled tools to produce precise, complex parts with high repeatability and minimal human intervention. Explore how these technologies compare and complement each other to optimize production workflows.

Why it is important

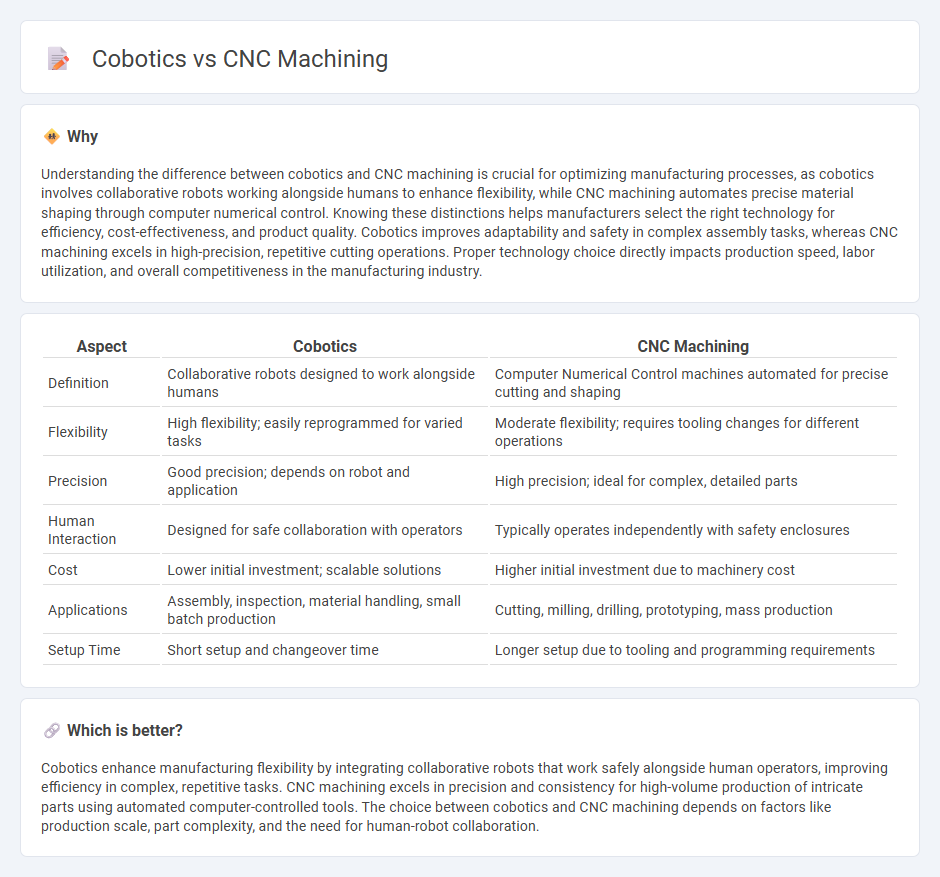

Understanding the difference between cobotics and CNC machining is crucial for optimizing manufacturing processes, as cobotics involves collaborative robots working alongside humans to enhance flexibility, while CNC machining automates precise material shaping through computer numerical control. Knowing these distinctions helps manufacturers select the right technology for efficiency, cost-effectiveness, and product quality. Cobotics improves adaptability and safety in complex assembly tasks, whereas CNC machining excels in high-precision, repetitive cutting operations. Proper technology choice directly impacts production speed, labor utilization, and overall competitiveness in the manufacturing industry.

Comparison Table

| Aspect | Cobotics | CNC Machining |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans | Computer Numerical Control machines automated for precise cutting and shaping |

| Flexibility | High flexibility; easily reprogrammed for varied tasks | Moderate flexibility; requires tooling changes for different operations |

| Precision | Good precision; depends on robot and application | High precision; ideal for complex, detailed parts |

| Human Interaction | Designed for safe collaboration with operators | Typically operates independently with safety enclosures |

| Cost | Lower initial investment; scalable solutions | Higher initial investment due to machinery cost |

| Applications | Assembly, inspection, material handling, small batch production | Cutting, milling, drilling, prototyping, mass production |

| Setup Time | Short setup and changeover time | Longer setup due to tooling and programming requirements |

Which is better?

Cobotics enhance manufacturing flexibility by integrating collaborative robots that work safely alongside human operators, improving efficiency in complex, repetitive tasks. CNC machining excels in precision and consistency for high-volume production of intricate parts using automated computer-controlled tools. The choice between cobotics and CNC machining depends on factors like production scale, part complexity, and the need for human-robot collaboration.

Connection

Cobotics enhances CNC machining by integrating collaborative robots that assist operators in precision tasks, improving efficiency and reducing human error. CNC machines benefit from cobots through automated loading, unloading, and tool changes, increasing production speed and consistency. This synergy boosts manufacturing flexibility and enables more complex, high-quality parts to be produced with minimal downtime.

Key Terms

Automation

CNC machining offers precise, repeatable automation for manufacturing complex parts with high accuracy, leveraging computer-controlled cutting tools to enhance production efficiency. Cobotics integrates collaborative robots alongside human workers to automate flexible, adaptive tasks, improving safety and productivity in dynamic manufacturing environments. Explore how combining CNC machining and cobotics can revolutionize your automation strategy.

Precision

CNC machining offers unparalleled precision with tolerances often within microns, ideal for complex, high-accuracy parts in aerospace and medical industries. Cobotics enhances precision by combining human oversight with robotic repeatability, improving flexibility and reducing human error in assembly and manufacturing tasks. Discover how integrating CNC machining and cobotics can elevate your production accuracy and efficiency.

Human-robot collaboration

CNC machining offers precise, automated control of cutting tools for complex parts, minimizing human error but requiring skilled operators for programming and setup. Cobotics emphasizes human-robot collaboration, enabling robots to assist workers safely and adaptively while enhancing productivity in dynamic environments. Explore how combining CNC machining with cobotic systems can revolutionize manufacturing efficiency and workforce safety.

Source and External Links

Online CNC Machining Service | Get a Quote - Protolabs - CNC machining is an automated subtractive manufacturing process where a solid block of material is precisely shaped into parts using computer-controlled end mills, widely used for prototypes and production with benefits like precision, tight tolerances, and quick turnaround in industries such as aerospace, medical, and automotive.

Custom Online CNC Machining Services - Metal and Plastic Instant Quote | Xometry - CNC machining differs from traditional machining by using computer numerical control software to drive automated cutting tools with high precision and repeatability, making it ideal for digital manufacturing and modifications, especially for metal and plastic parts.

CNC machining: The manufacturing & design guide | Hubs - CNC machining is a subtractive technology that removes material from a solid workpiece using computer-controlled cutting tools based on CAD files, producing high-accuracy parts with excellent physical properties, distinct from additive or formative manufacturing technologies.

dowidth.com

dowidth.com