Process mining in manufacturing leverages data from production systems to visualize, analyze, and optimize real-time workflows, identifying inefficiencies and ensuring process compliance. Total Quality Management (TQM) focuses on continuous improvement by involving all employees in defect prevention, customer satisfaction, and quality control through structured methodologies and standards. Explore how integrating process mining with TQM principles can revolutionize manufacturing quality and operational excellence.

Why it is important

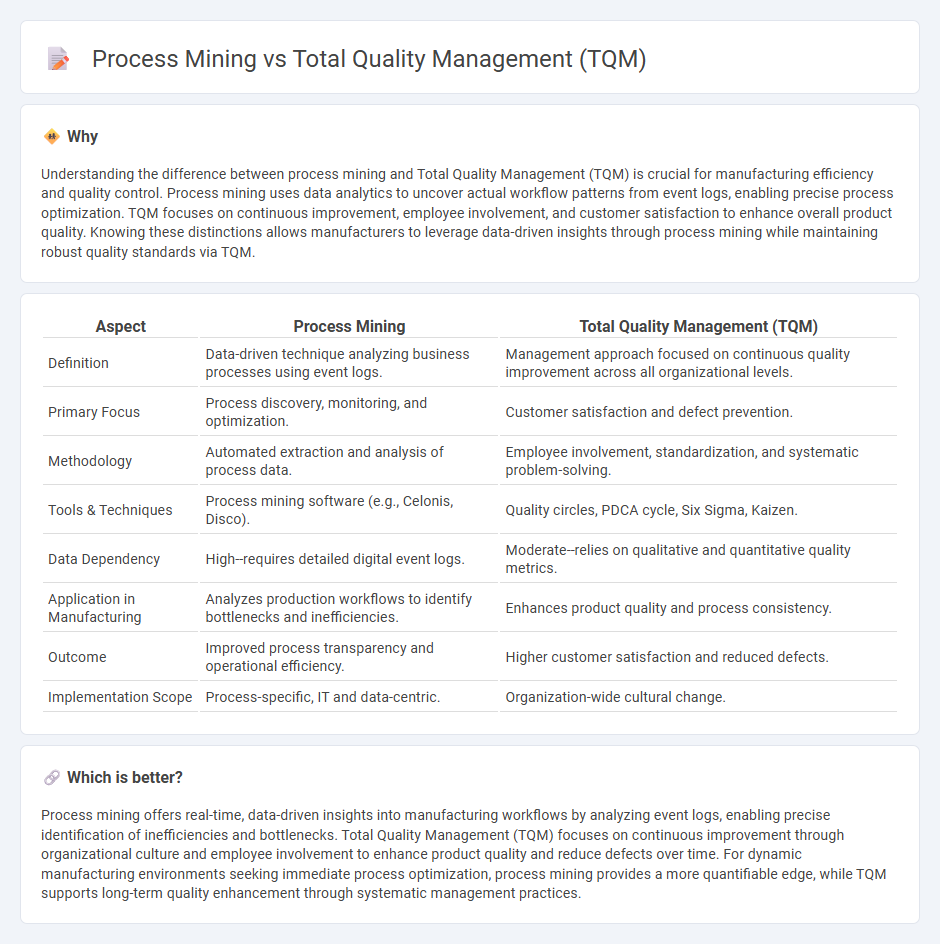

Understanding the difference between process mining and Total Quality Management (TQM) is crucial for manufacturing efficiency and quality control. Process mining uses data analytics to uncover actual workflow patterns from event logs, enabling precise process optimization. TQM focuses on continuous improvement, employee involvement, and customer satisfaction to enhance overall product quality. Knowing these distinctions allows manufacturers to leverage data-driven insights through process mining while maintaining robust quality standards via TQM.

Comparison Table

| Aspect | Process Mining | Total Quality Management (TQM) |

|---|---|---|

| Definition | Data-driven technique analyzing business processes using event logs. | Management approach focused on continuous quality improvement across all organizational levels. |

| Primary Focus | Process discovery, monitoring, and optimization. | Customer satisfaction and defect prevention. |

| Methodology | Automated extraction and analysis of process data. | Employee involvement, standardization, and systematic problem-solving. |

| Tools & Techniques | Process mining software (e.g., Celonis, Disco). | Quality circles, PDCA cycle, Six Sigma, Kaizen. |

| Data Dependency | High--requires detailed digital event logs. | Moderate--relies on qualitative and quantitative quality metrics. |

| Application in Manufacturing | Analyzes production workflows to identify bottlenecks and inefficiencies. | Enhances product quality and process consistency. |

| Outcome | Improved process transparency and operational efficiency. | Higher customer satisfaction and reduced defects. |

| Implementation Scope | Process-specific, IT and data-centric. | Organization-wide cultural change. |

Which is better?

Process mining offers real-time, data-driven insights into manufacturing workflows by analyzing event logs, enabling precise identification of inefficiencies and bottlenecks. Total Quality Management (TQM) focuses on continuous improvement through organizational culture and employee involvement to enhance product quality and reduce defects over time. For dynamic manufacturing environments seeking immediate process optimization, process mining provides a more quantifiable edge, while TQM supports long-term quality enhancement through systematic management practices.

Connection

Process mining enhances Total Quality Management (TQM) by providing data-driven insights into manufacturing workflows, enabling identification of inefficiencies and deviations from quality standards. By analyzing event logs, process mining uncovers bottlenecks and non-compliance issues, supporting continuous improvement initiatives central to TQM. Integrating process mining with TQM facilitates real-time monitoring and data-based decision-making, thereby improving product quality and operational excellence.

Key Terms

Continuous Improvement (TQM)

Total Quality Management (TQM) emphasizes continuous improvement by integrating customer feedback, employee involvement, and systematic process analysis to enhance product and service quality. Process mining applies advanced data analytics to visualize, analyze, and optimize business processes, uncovering inefficiencies and enabling data-driven continuous improvement. Explore the synergy between TQM principles and process mining techniques to drive sustainable organizational excellence.

Event Logs (Process Mining)

Event logs serve as the foundational data in process mining, capturing detailed, time-stamped records of business processes that enable precise analysis of workflow performance and bottlenecks. Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction through systematic process controls and employee involvement without relying exclusively on automated data. Exploring how event logs enhance TQM practices can reveal new opportunities for process optimization and quality assurance. Discover more about integrating event log analysis with TQM strategies to boost organizational efficiency.

Root Cause Analysis (TQM)

Total Quality Management (TQM) emphasizes Root Cause Analysis (RCA) to identify fundamental issues affecting quality, using tools like fishbone diagrams and the 5 Whys technique for continuous improvement. Process mining enhances RCA by leveraging data-driven insights from event logs to uncover process deviations and inefficiencies automatically. Explore how integrating TQM principles with process mining can revolutionize root cause identification and operational excellence.

Source and External Links

What is Total Quality Management? | Definition from TechTarget - Total Quality Management (TQM) is a long-term management framework where all members of an organization work together to improve quality and ensure customer satisfaction through continuous internal and process improvements across all departments.

Total Quality Management (TQM) - Corporate Finance Institute - TQM is a comprehensive approach emphasizing continuous improvement, teamwork, and customer satisfaction by embedding quality in every organizational process and leveraging data-driven decision making to enhance performance and competitiveness.

Mastering the 8 Principles of TQM (Total Quality Management) - TQM is guided by eight core principles including client-centricity, leadership, inclusion, continuous refinement, and evidence-based decisions, fostering a culture shift toward teamwork and quality to achieve sustained business success and customer satisfaction.

dowidth.com

dowidth.com