Automated guided vehicles (AGVs) enhance manufacturing efficiency through precise navigation and reduced labor costs, outperforming traditional forklifts in safety and scalability. Forklifts remain essential for heavy lifting and flexible material handling in dynamic factory environments. Discover how integrating AGVs can transform your manufacturing operations.

Why it is important

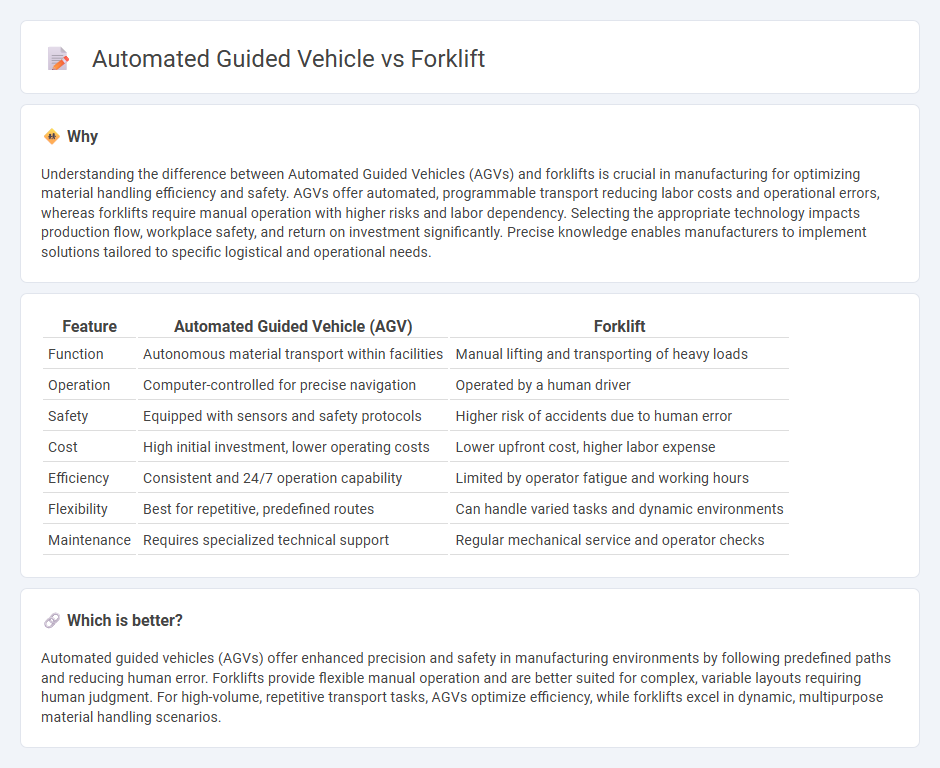

Understanding the difference between Automated Guided Vehicles (AGVs) and forklifts is crucial in manufacturing for optimizing material handling efficiency and safety. AGVs offer automated, programmable transport reducing labor costs and operational errors, whereas forklifts require manual operation with higher risks and labor dependency. Selecting the appropriate technology impacts production flow, workplace safety, and return on investment significantly. Precise knowledge enables manufacturers to implement solutions tailored to specific logistical and operational needs.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Forklift |

|---|---|---|

| Function | Autonomous material transport within facilities | Manual lifting and transporting of heavy loads |

| Operation | Computer-controlled for precise navigation | Operated by a human driver |

| Safety | Equipped with sensors and safety protocols | Higher risk of accidents due to human error |

| Cost | High initial investment, lower operating costs | Lower upfront cost, higher labor expense |

| Efficiency | Consistent and 24/7 operation capability | Limited by operator fatigue and working hours |

| Flexibility | Best for repetitive, predefined routes | Can handle varied tasks and dynamic environments |

| Maintenance | Requires specialized technical support | Regular mechanical service and operator checks |

Which is better?

Automated guided vehicles (AGVs) offer enhanced precision and safety in manufacturing environments by following predefined paths and reducing human error. Forklifts provide flexible manual operation and are better suited for complex, variable layouts requiring human judgment. For high-volume, repetitive transport tasks, AGVs optimize efficiency, while forklifts excel in dynamic, multipurpose material handling scenarios.

Connection

Automated guided vehicles (AGVs) and forklifts both optimize material handling in manufacturing by streamlining the transport of goods across production floors. AGVs enhance efficiency through autonomous navigation and programmable routes, while forklifts provide versatile lifting capabilities for heavy loads. Integrating AGVs with forklifts enables seamless coordination, reducing manual labor and minimizing downtime in manufacturing processes.

Key Terms

Material Handling

Forklifts and Automated Guided Vehicles (AGVs) are pivotal in material handling, with forklifts offering versatile, manual operation for lifting and transporting heavy loads in dynamic environments, while AGVs provide automated, efficient, and precise movement ideal for repetitive tasks in controlled settings. Forklifts excel in flexibility and handling diverse load types, whereas AGVs enhance safety and reduce labor costs by operating autonomously with programmed routes. Explore the detailed comparison to determine the best fit for optimizing your material handling processes.

Automation

Automated guided vehicles (AGVs) offer superior automation capabilities compared to traditional forklifts, enabling seamless integration with warehouse management systems and reducing human intervention. AGVs utilize advanced navigation technologies such as LiDAR, RFID, and GPS to enhance precision and efficiency in material handling. Explore how AGVs can revolutionize your logistics operations with cutting-edge automated solutions.

Safety

Forklifts pose higher safety risks due to manual operation, including collisions and tip-overs, while Automated Guided Vehicles (AGVs) enhance workplace safety with precise navigation and reduced human error. AGVs are equipped with sensors and real-time monitoring systems to detect obstacles and prevent accidents, significantly lowering injury rates in industrial environments. Explore detailed comparisons of forklift and AGV safety features to optimize your facility's risk management strategies.

Source and External Links

Forklift - A powered industrial truck used for lifting and moving materials over short distances, available in various load capacities and types.

Forklift Certification Training - An online course that complies with OSHA standards for training forklift operators, covering Class I to Class VII forklifts.

Toyota Forklifts - Offers a range of material handling solutions, including electric pneumatic forklifts with lifting capacities from 8,000 to 17,500 lbs.

dowidth.com

dowidth.com