Dark factories leverage fully automated production processes operating without human presence, maximizing efficiency and reducing labor costs. Additive manufacturing, known as 3D printing, builds products layer by layer from digital models, enabling complex designs and rapid prototyping. Discover how these innovative approaches are transforming the future of manufacturing.

Why it is important

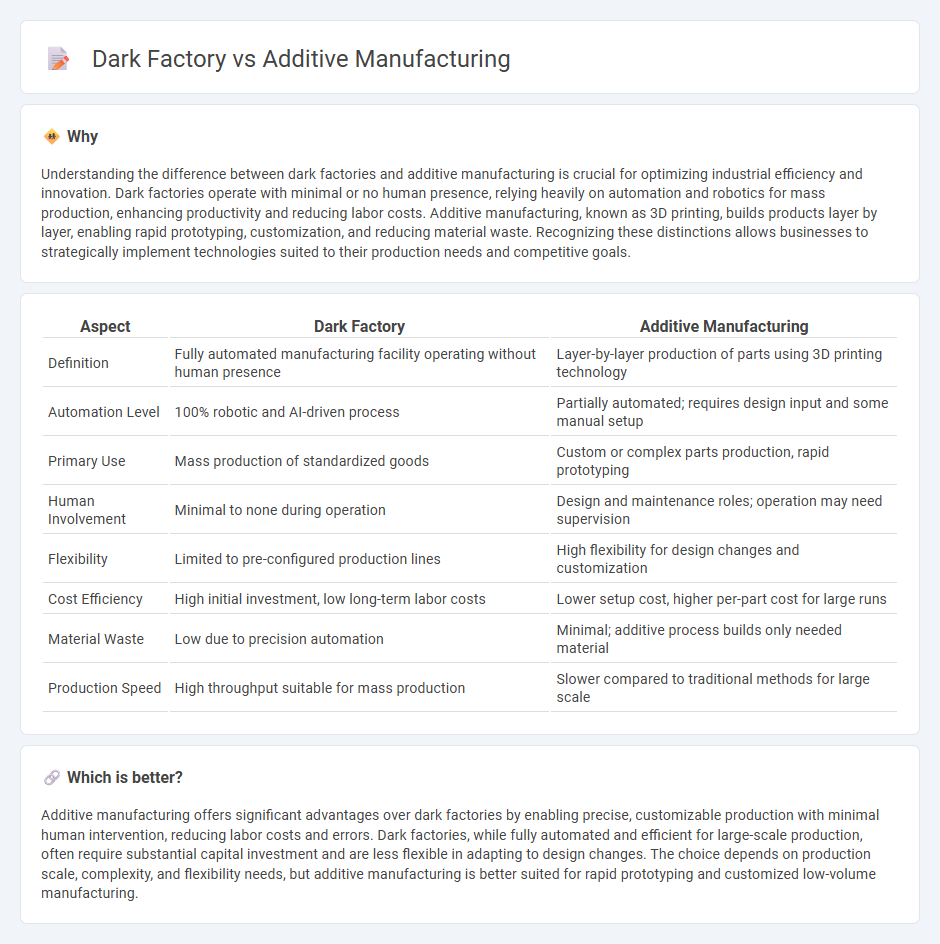

Understanding the difference between dark factories and additive manufacturing is crucial for optimizing industrial efficiency and innovation. Dark factories operate with minimal or no human presence, relying heavily on automation and robotics for mass production, enhancing productivity and reducing labor costs. Additive manufacturing, known as 3D printing, builds products layer by layer, enabling rapid prototyping, customization, and reducing material waste. Recognizing these distinctions allows businesses to strategically implement technologies suited to their production needs and competitive goals.

Comparison Table

| Aspect | Dark Factory | Additive Manufacturing |

|---|---|---|

| Definition | Fully automated manufacturing facility operating without human presence | Layer-by-layer production of parts using 3D printing technology |

| Automation Level | 100% robotic and AI-driven process | Partially automated; requires design input and some manual setup |

| Primary Use | Mass production of standardized goods | Custom or complex parts production, rapid prototyping |

| Human Involvement | Minimal to none during operation | Design and maintenance roles; operation may need supervision |

| Flexibility | Limited to pre-configured production lines | High flexibility for design changes and customization |

| Cost Efficiency | High initial investment, low long-term labor costs | Lower setup cost, higher per-part cost for large runs |

| Material Waste | Low due to precision automation | Minimal; additive process builds only needed material |

| Production Speed | High throughput suitable for mass production | Slower compared to traditional methods for large scale |

Which is better?

Additive manufacturing offers significant advantages over dark factories by enabling precise, customizable production with minimal human intervention, reducing labor costs and errors. Dark factories, while fully automated and efficient for large-scale production, often require substantial capital investment and are less flexible in adapting to design changes. The choice depends on production scale, complexity, and flexibility needs, but additive manufacturing is better suited for rapid prototyping and customized low-volume manufacturing.

Connection

Dark factories utilize automation and AI-driven systems to operate manufacturing processes without human presence, enhancing efficiency and precision. Additive manufacturing, or 3D printing, perfectly complements dark factory environments by enabling on-demand, customizable production through layer-by-layer material deposition. Integrating additive manufacturing in dark factories accelerates product development cycles while minimizing errors and material waste.

Key Terms

3D Printing

Additive manufacturing, commonly known as 3D printing, builds objects layer by layer using materials such as plastics, metals, or composites, enabling rapid prototyping and complex geometries not achievable with traditional methods. Dark factories leverage automation technology, including robotic arms and AI, to operate 24/7 without human presence, often incorporating additive manufacturing for efficient production under controlled environments. Explore how integrating 3D printing within dark factories transforms manufacturing efficiency and scalability by visiting our in-depth resource.

Automation

Additive manufacturing leverages automated 3D printing technologies to produce complex parts layer by layer with minimal human intervention, significantly enhancing precision and reducing production time. Dark factories operate fully automated production lines in complete darkness, utilizing robotics and AI to maximize efficiency and eliminate the need for onsite human labor. Discover how these automation-driven innovations transform modern manufacturing processes.

Lights-Out Manufacturing

Additive manufacturing enables precise, layer-by-layer production with minimal waste, while dark factories operate fully automated, lights-out environments maximizing efficiency and reducing labor costs. Lights-out manufacturing integrates robotics and AI to run additive processes continuously without human intervention, enhancing productivity and consistency. Explore how combining additive manufacturing with dark factory principles revolutionizes lights-out manufacturing.

Source and External Links

Additive manufacturing, explained | MIT Sloan - Additive manufacturing is the process of building objects layer by layer from digital designs, often known as 3D printing, originally used for rapid prototyping and now for creating functional products with a wide range of materials like polymers, metals, and biomaterials.

Additive manufacturing | NIST - Additive manufacturing, or 3D printing, fabricates objects by adding material layer-by-layer from digital models, enabling complex designs with less waste, and is critical for applications including aerospace and biomedical implants using materials like metals, plastics, and ceramics.

The 7 categories of Additive Manufacturing - Loughborough University - Additive manufacturing encompasses several varied technologies classified into seven categories by ASTM, including VAT photopolymerization, material jetting, and binder jetting, each differing in materials and processes used to build layers.

dowidth.com

dowidth.com