Machine vision inspection utilizes cameras and image processing algorithms to detect defects and ensure quality in manufacturing lines, providing real-time, non-contact analysis for high-speed production. Laser scanning captures precise 3D surface data by measuring distance with laser beams, excelling in dimensional accuracy and complex geometry evaluation. Discover how these advanced technologies can enhance your manufacturing quality control processes.

Why it is important

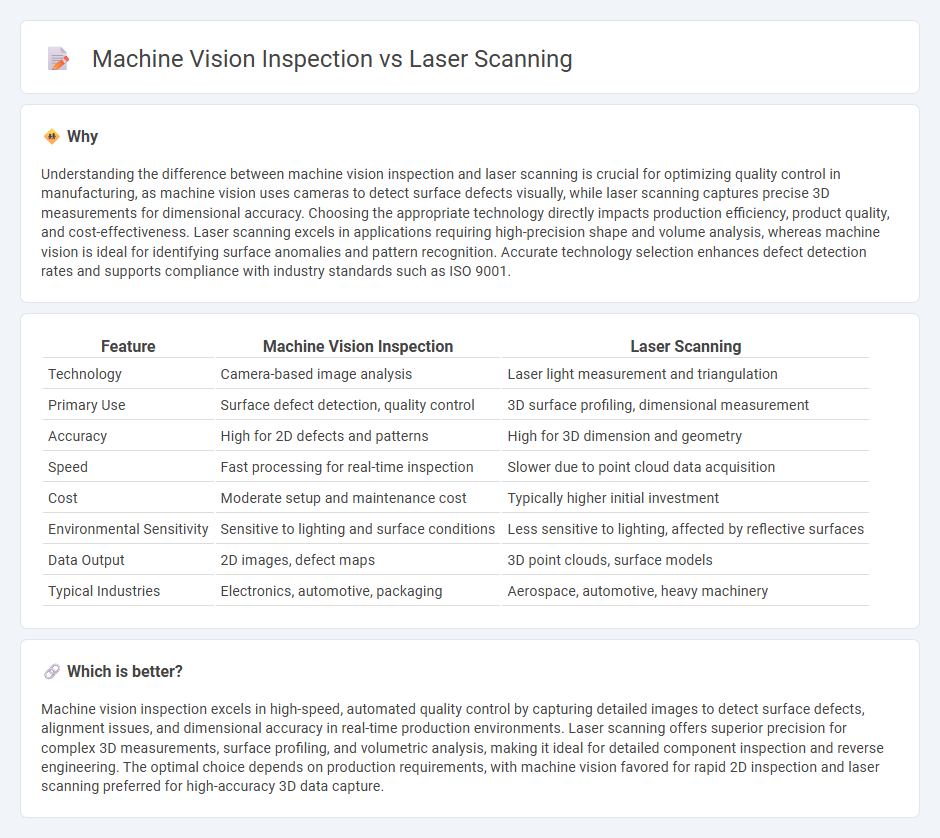

Understanding the difference between machine vision inspection and laser scanning is crucial for optimizing quality control in manufacturing, as machine vision uses cameras to detect surface defects visually, while laser scanning captures precise 3D measurements for dimensional accuracy. Choosing the appropriate technology directly impacts production efficiency, product quality, and cost-effectiveness. Laser scanning excels in applications requiring high-precision shape and volume analysis, whereas machine vision is ideal for identifying surface anomalies and pattern recognition. Accurate technology selection enhances defect detection rates and supports compliance with industry standards such as ISO 9001.

Comparison Table

| Feature | Machine Vision Inspection | Laser Scanning |

|---|---|---|

| Technology | Camera-based image analysis | Laser light measurement and triangulation |

| Primary Use | Surface defect detection, quality control | 3D surface profiling, dimensional measurement |

| Accuracy | High for 2D defects and patterns | High for 3D dimension and geometry |

| Speed | Fast processing for real-time inspection | Slower due to point cloud data acquisition |

| Cost | Moderate setup and maintenance cost | Typically higher initial investment |

| Environmental Sensitivity | Sensitive to lighting and surface conditions | Less sensitive to lighting, affected by reflective surfaces |

| Data Output | 2D images, defect maps | 3D point clouds, surface models |

| Typical Industries | Electronics, automotive, packaging | Aerospace, automotive, heavy machinery |

Which is better?

Machine vision inspection excels in high-speed, automated quality control by capturing detailed images to detect surface defects, alignment issues, and dimensional accuracy in real-time production environments. Laser scanning offers superior precision for complex 3D measurements, surface profiling, and volumetric analysis, making it ideal for detailed component inspection and reverse engineering. The optimal choice depends on production requirements, with machine vision favored for rapid 2D inspection and laser scanning preferred for high-accuracy 3D data capture.

Connection

Machine vision inspection and laser scanning are connected through their ability to enhance precision in manufacturing quality control by capturing detailed surface and dimensional data. Machine vision inspection uses cameras and image processing algorithms to detect defects and ensure component accuracy, while laser scanning provides high-resolution 3D measurements for precise geometry analysis. Integrating both technologies optimizes defect detection, reduces production errors, and improves overall manufacturing efficiency.

Key Terms

Surface Profiling

Laser scanning offers precise 3D surface profiling by emitting laser beams to capture detailed topography, making it ideal for complex geometries and accurate depth measurements. Machine vision inspection relies on high-resolution cameras and image processing algorithms to analyze surface features, providing rapid defect detection but with limitations in capturing fine depth variations. Explore the advanced capabilities of laser scanning and machine vision inspection for enhanced surface profiling accuracy and efficiency.

Defect Detection

Laser scanning excels in defect detection by producing high-resolution 3D surface profiles, enabling precise identification of dimensional inaccuracies and surface anomalies. Machine vision inspection uses 2D image analysis to detect color variations, surface defects, and pattern inconsistencies but may struggle with depth-related flaws. Explore the strengths and applications of laser scanning and machine vision to optimize your defect detection strategy.

Dimensional Measurement

Laser scanning delivers high-precision dimensional measurement by capturing detailed 3D surface data with accuracy up to microns, ideal for complex geometries and quality control in manufacturing. Machine vision inspection excels in real-time dimensional checks using 2D or 3D cameras combined with advanced image processing algorithms, enabling rapid defect detection and automated measurement on production lines. Explore how integrating laser scanning with machine vision can optimize dimensional measurement performance and ensure superior product quality.

Source and External Links

Understanding Laser Scanners | Article - FARO Technologies - Laser scanners are non-contact devices that emit infrared laser beams, measure reflected light to capture millions of 3D data points, and use either time-of-flight or phase-shift systems for precise distance calculation.

3D Laser Scanning | Benefits & How It Works - Autodesk - 3D laser scanning rapidly emits laser beams to measure distances and create dense point-cloud models of objects or environments, widely used in architecture, construction, and facility management for accurate as-built documentation.

Laser scanning - Wikipedia - Laser scanning involves steering laser beams combined with a rangefinder to rapidly capture the surface shape of objects, buildings, or landscapes, with applications in 3D modeling, surveying, and archaeology, often called lidar in mapping contexts.

dowidth.com

dowidth.com