Digital twin technology creates a virtual replica of physical manufacturing processes, enabling real-time simulation, monitoring, and predictive maintenance, while SCADA systems focus on real-time data acquisition and control of industrial equipment. Digital twins offer enhanced insights by integrating IoT data, advanced analytics, and machine learning to optimize operations beyond the capabilities of traditional SCADA systems. Explore how combining digital twin and SCADA technologies revolutionizes manufacturing efficiency and decision-making.

Why it is important

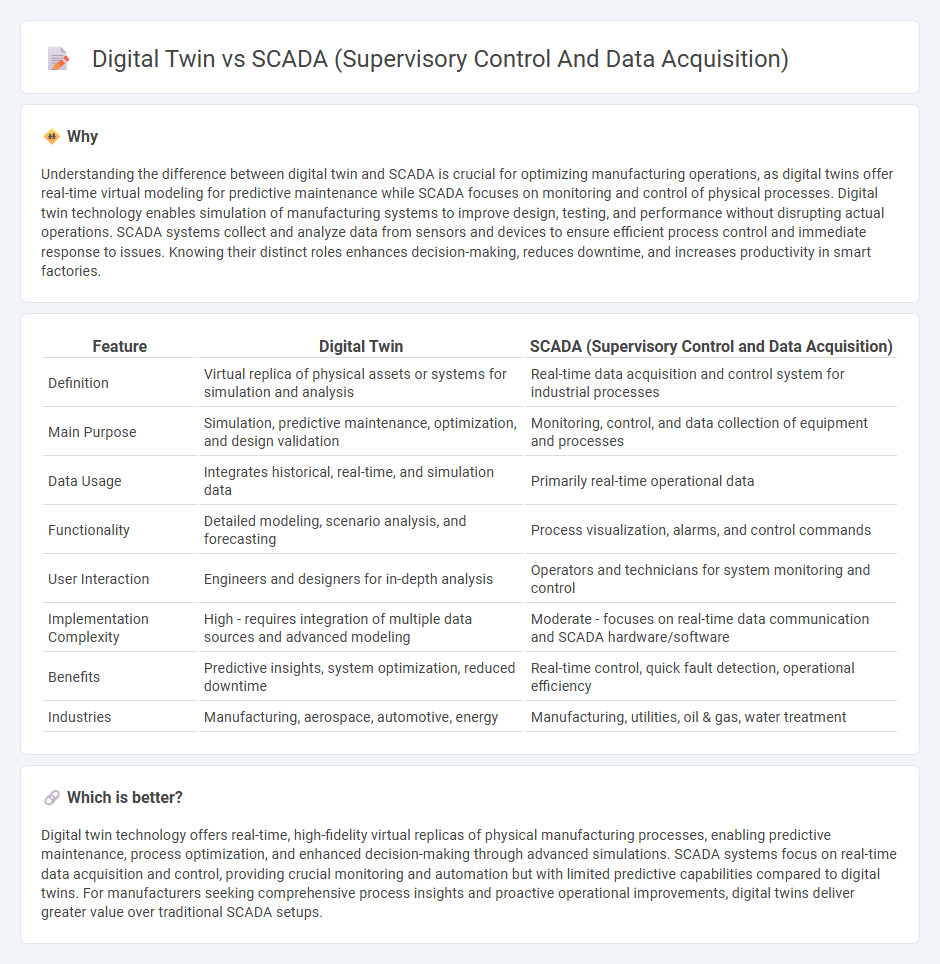

Understanding the difference between digital twin and SCADA is crucial for optimizing manufacturing operations, as digital twins offer real-time virtual modeling for predictive maintenance while SCADA focuses on monitoring and control of physical processes. Digital twin technology enables simulation of manufacturing systems to improve design, testing, and performance without disrupting actual operations. SCADA systems collect and analyze data from sensors and devices to ensure efficient process control and immediate response to issues. Knowing their distinct roles enhances decision-making, reduces downtime, and increases productivity in smart factories.

Comparison Table

| Feature | Digital Twin | SCADA (Supervisory Control and Data Acquisition) |

|---|---|---|

| Definition | Virtual replica of physical assets or systems for simulation and analysis | Real-time data acquisition and control system for industrial processes |

| Main Purpose | Simulation, predictive maintenance, optimization, and design validation | Monitoring, control, and data collection of equipment and processes |

| Data Usage | Integrates historical, real-time, and simulation data | Primarily real-time operational data |

| Functionality | Detailed modeling, scenario analysis, and forecasting | Process visualization, alarms, and control commands |

| User Interaction | Engineers and designers for in-depth analysis | Operators and technicians for system monitoring and control |

| Implementation Complexity | High - requires integration of multiple data sources and advanced modeling | Moderate - focuses on real-time data communication and SCADA hardware/software |

| Benefits | Predictive insights, system optimization, reduced downtime | Real-time control, quick fault detection, operational efficiency |

| Industries | Manufacturing, aerospace, automotive, energy | Manufacturing, utilities, oil & gas, water treatment |

Which is better?

Digital twin technology offers real-time, high-fidelity virtual replicas of physical manufacturing processes, enabling predictive maintenance, process optimization, and enhanced decision-making through advanced simulations. SCADA systems focus on real-time data acquisition and control, providing crucial monitoring and automation but with limited predictive capabilities compared to digital twins. For manufacturers seeking comprehensive process insights and proactive operational improvements, digital twins deliver greater value over traditional SCADA setups.

Connection

Digital twin technology integrates seamlessly with SCADA systems by utilizing real-time data collected from sensors and control devices to create accurate virtual replicas of physical manufacturing processes. This synergy enables enhanced monitoring, predictive maintenance, and optimization of equipment performance, reducing downtime and operational costs. By combining SCADA's data acquisition capabilities with digital twin simulations, manufacturers achieve improved decision-making and increased efficiency in production workflows.

Key Terms

Real-time Monitoring

SCADA systems excel in real-time monitoring by collecting and visualizing live data from industrial processes, enabling immediate detection and response to operational anomalies. Digital twins offer advanced real-time monitoring through dynamic, virtual replicas of physical assets, allowing predictive analysis and simulation-based decision-making. Explore how integrating SCADA with digital twin technology transforms real-time operational insights and efficiency.

Virtual Simulation

SCADA systems provide real-time monitoring and control of industrial processes by collecting data from sensors and equipment, ensuring operational efficiency and safety. Digital twins create virtual simulations of physical assets or systems, allowing predictive analysis, performance optimization, and scenario testing without disrupting actual operations. Explore the advanced differences between SCADA and digital twins to enhance industrial automation strategies.

Data Integration

SCADA systems primarily handle real-time data acquisition and control from physical processes, enabling centralized monitoring and automation across industrial environments. Digital twins integrate vast datasets, including historical, real-time, and predictive analytics, to create dynamic virtual models that simulate and optimize complex systems throughout their lifecycle. Explore the transformative potential of advanced data integration by learning more about SCADA and digital twin technologies.

Source and External Links

What is SCADA (Supervisory Control and Data Acquisition)? - SCADA is a system used for controlling and monitoring industrial processes over large areas by collecting data from sensors and devices via RTUs and PLCs, processing it centrally, and enabling operators to control processes and receive alerts on anomalies in real time.

What is SCADA? Supervisory Control and Data Acquisition - SCADA is a combination of software and hardware that allows organizations to monitor and control industrial machinery and processes remotely via sensors, PLCs, RTUs, and human-machine interfaces (HMIs), helping improve efficiency and reduce downtime.

What is SCADA? Supervisory Control and Data Acquisition - PTC - SCADA systems act as an intermediary layer collecting data from RTUs and PLCs to present real-time visualization, alarm management, and reporting to operators, facilitating supervisory control and data acquisition for informed decision-making and long-term analysis.

dowidth.com

dowidth.com