Smart factories leverage advanced technologies such as IoT, AI, and automation to optimize production processes, enhance real-time data analysis, and improve overall efficiency. Just-in-time (JIT) manufacturing focuses on reducing inventory costs by producing goods only as needed, minimizing waste and streamlining supply chain management. Explore the differences in benefits and implementations of smart factories versus JIT manufacturing to boost your production strategy.

Why it is important

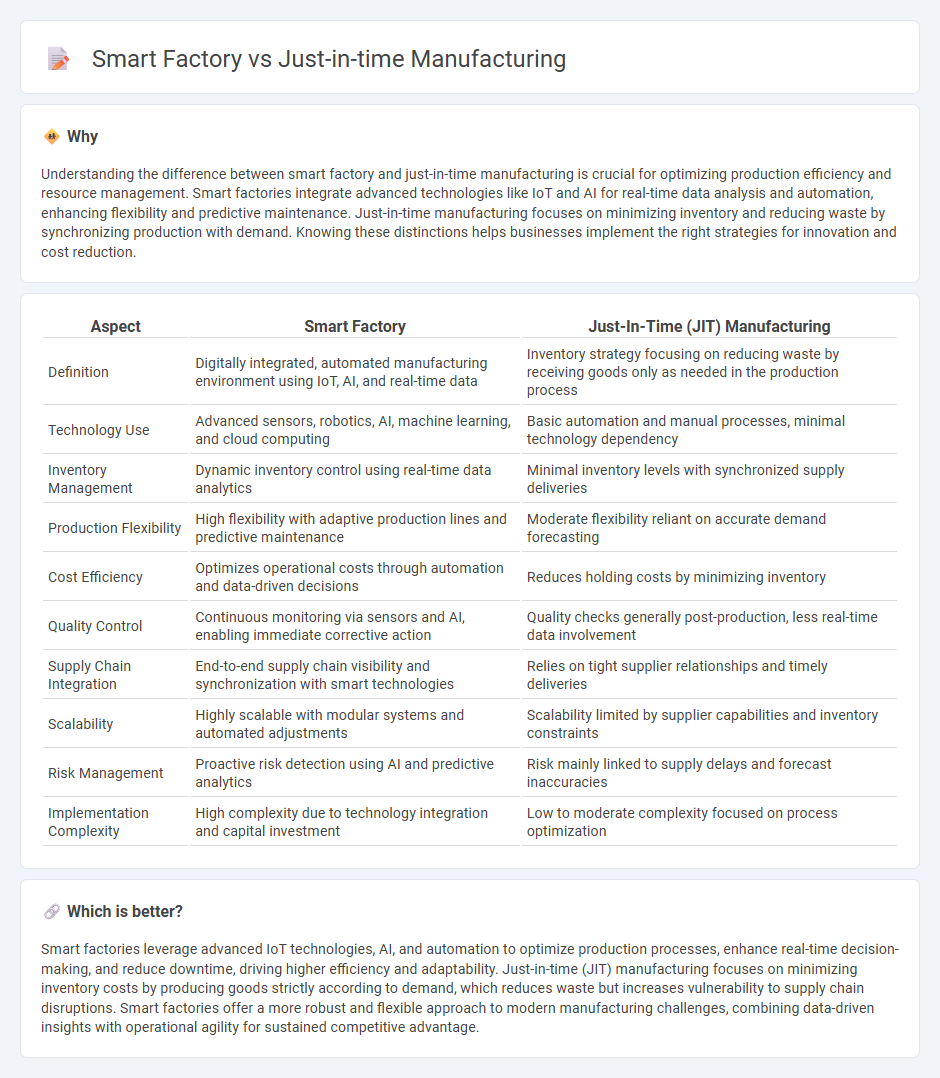

Understanding the difference between smart factory and just-in-time manufacturing is crucial for optimizing production efficiency and resource management. Smart factories integrate advanced technologies like IoT and AI for real-time data analysis and automation, enhancing flexibility and predictive maintenance. Just-in-time manufacturing focuses on minimizing inventory and reducing waste by synchronizing production with demand. Knowing these distinctions helps businesses implement the right strategies for innovation and cost reduction.

Comparison Table

| Aspect | Smart Factory | Just-In-Time (JIT) Manufacturing |

|---|---|---|

| Definition | Digitally integrated, automated manufacturing environment using IoT, AI, and real-time data | Inventory strategy focusing on reducing waste by receiving goods only as needed in the production process |

| Technology Use | Advanced sensors, robotics, AI, machine learning, and cloud computing | Basic automation and manual processes, minimal technology dependency |

| Inventory Management | Dynamic inventory control using real-time data analytics | Minimal inventory levels with synchronized supply deliveries |

| Production Flexibility | High flexibility with adaptive production lines and predictive maintenance | Moderate flexibility reliant on accurate demand forecasting |

| Cost Efficiency | Optimizes operational costs through automation and data-driven decisions | Reduces holding costs by minimizing inventory |

| Quality Control | Continuous monitoring via sensors and AI, enabling immediate corrective action | Quality checks generally post-production, less real-time data involvement |

| Supply Chain Integration | End-to-end supply chain visibility and synchronization with smart technologies | Relies on tight supplier relationships and timely deliveries |

| Scalability | Highly scalable with modular systems and automated adjustments | Scalability limited by supplier capabilities and inventory constraints |

| Risk Management | Proactive risk detection using AI and predictive analytics | Risk mainly linked to supply delays and forecast inaccuracies |

| Implementation Complexity | High complexity due to technology integration and capital investment | Low to moderate complexity focused on process optimization |

Which is better?

Smart factories leverage advanced IoT technologies, AI, and automation to optimize production processes, enhance real-time decision-making, and reduce downtime, driving higher efficiency and adaptability. Just-in-time (JIT) manufacturing focuses on minimizing inventory costs by producing goods strictly according to demand, which reduces waste but increases vulnerability to supply chain disruptions. Smart factories offer a more robust and flexible approach to modern manufacturing challenges, combining data-driven insights with operational agility for sustained competitive advantage.

Connection

Smart factories utilize real-time data analytics and automation to streamline production processes, enabling just-in-time manufacturing to reduce inventory costs and minimize waste. The integration of IoT sensors and AI in smart factories facilitates precise demand forecasting and adaptive scheduling, enhancing the efficiency of just-in-time systems. This connectivity ensures seamless coordination across supply chains, optimizing resource allocation and accelerating response times in manufacturing operations.

Key Terms

Inventory Management

Just-in-time manufacturing minimizes inventory levels by synchronizing production schedules with demand forecasts, reducing waste and storage costs through precise timing of material arrivals. Smart factories leverage IoT sensors and AI-driven analytics to monitor and optimize inventory in real-time, enabling predictive replenishment and enhanced supply chain visibility. Explore how integrating these approaches can revolutionize inventory management efficiency and responsiveness.

Automation

Just-in-time (JIT) manufacturing minimizes inventory and waste by synchronizing production schedules with demand, heavily relying on automation to ensure timely material flow and efficient processes. Smart factories leverage advanced automation technologies like IoT, AI, and robotics to create highly flexible, adaptive production environments capable of real-time data analysis and autonomous decision-making. Explore more to understand how these automation strategies transform manufacturing efficiency and competitiveness.

Real-Time Data

Just-in-time manufacturing relies on minimizing inventory by synchronizing production schedules with demand using real-time data to reduce waste and improve efficiency. Smart factories leverage advanced sensors, IoT devices, and AI analytics to continuously monitor and optimize every aspect of the production process in real time. Explore how integrating real-time data transforms manufacturing operations in both methodologies for enhanced productivity and agility.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just-in-time manufacturing is a strategy that increases efficiency and reduces waste by producing goods only as needed, matching supply with demand, lowering inventory costs, and improving quality through continuous monitoring and supplier collaboration.

What is just-in-time manufacturing (JIT manufacturing)? - TechTarget - JIT manufacturing is a production model where items are made to meet actual demand, avoiding overproduction and minimizing waste like excess inventory and wait times, thereby increasing efficiency and reducing costs.

JIT Just-in-Time manufacturing - JIT is a management philosophy focused on producing goods exactly when needed, in the right quantity and quality, aiming to eliminate all forms of waste--including time, resources, and materials--through continuous improvement and problem-solving.

dowidth.com

dowidth.com