Lights out factories leverage full automation to operate autonomously without human intervention, maximizing production efficiency and reducing labor costs. Total Productive Maintenance (TPM) emphasizes proactive equipment maintenance involving all employees to minimize downtime and enhance machine reliability. Discover how combining lights out factory principles with TPM can revolutionize your manufacturing processes.

Why it is important

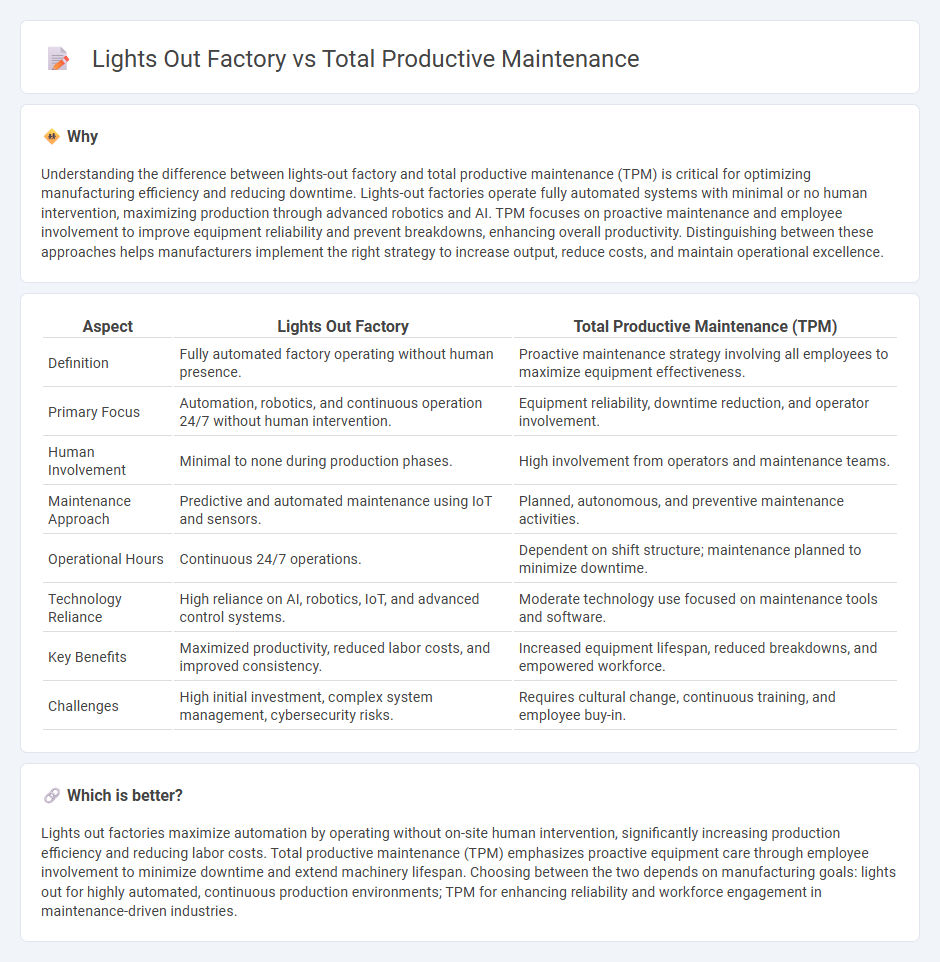

Understanding the difference between lights-out factory and total productive maintenance (TPM) is critical for optimizing manufacturing efficiency and reducing downtime. Lights-out factories operate fully automated systems with minimal or no human intervention, maximizing production through advanced robotics and AI. TPM focuses on proactive maintenance and employee involvement to improve equipment reliability and prevent breakdowns, enhancing overall productivity. Distinguishing between these approaches helps manufacturers implement the right strategy to increase output, reduce costs, and maintain operational excellence.

Comparison Table

| Aspect | Lights Out Factory | Total Productive Maintenance (TPM) |

|---|---|---|

| Definition | Fully automated factory operating without human presence. | Proactive maintenance strategy involving all employees to maximize equipment effectiveness. |

| Primary Focus | Automation, robotics, and continuous operation 24/7 without human intervention. | Equipment reliability, downtime reduction, and operator involvement. |

| Human Involvement | Minimal to none during production phases. | High involvement from operators and maintenance teams. |

| Maintenance Approach | Predictive and automated maintenance using IoT and sensors. | Planned, autonomous, and preventive maintenance activities. |

| Operational Hours | Continuous 24/7 operations. | Dependent on shift structure; maintenance planned to minimize downtime. |

| Technology Reliance | High reliance on AI, robotics, IoT, and advanced control systems. | Moderate technology use focused on maintenance tools and software. |

| Key Benefits | Maximized productivity, reduced labor costs, and improved consistency. | Increased equipment lifespan, reduced breakdowns, and empowered workforce. |

| Challenges | High initial investment, complex system management, cybersecurity risks. | Requires cultural change, continuous training, and employee buy-in. |

Which is better?

Lights out factories maximize automation by operating without on-site human intervention, significantly increasing production efficiency and reducing labor costs. Total productive maintenance (TPM) emphasizes proactive equipment care through employee involvement to minimize downtime and extend machinery lifespan. Choosing between the two depends on manufacturing goals: lights out for highly automated, continuous production environments; TPM for enhancing reliability and workforce engagement in maintenance-driven industries.

Connection

Lights-out factories rely heavily on Total Productive Maintenance (TPM) to ensure continuous, automated production with minimal human intervention. TPM practices optimize equipment reliability and prevent unexpected breakdowns, which is critical in the lights-out manufacturing environment to maintain operational efficiency. By emphasizing predictive and preventive maintenance, TPM enables seamless, 24/7 factory operation essential for the success of lights-out manufacturing.

Key Terms

**Total Productive Maintenance:**

Total Productive Maintenance (TPM) focuses on maximizing equipment effectiveness by involving all employees in proactive maintenance activities, reducing downtime, and improving productivity through continuous improvement and autonomous maintenance techniques. Unlike a lights-out factory that aims for fully automated, unmanned production, TPM emphasizes human-machine collaboration and preventive care to enhance asset reliability. Discover how Total Productive Maintenance can transform your manufacturing operations and boost overall efficiency.

Autonomous Maintenance

Total Productive Maintenance (TPM) emphasizes Autonomous Maintenance by empowering operators to perform routine equipment care, aiming to reduce breakdowns and improve machinery lifespan. In contrast, a Lights Out Factory operates fully automated production systems with minimal human intervention, relying heavily on advanced sensors and AI for maintenance and monitoring. Explore how Autonomous Maintenance integrates into both strategies to optimize operational efficiency and reliability.

Planned Maintenance

Total Productive Maintenance (TPM) emphasizes proactive planned maintenance to maximize equipment efficiency, reduce downtime, and engage operators in daily upkeep tasks. Lights Out Factory operations rely heavily on automated systems with predictive planned maintenance to ensure uninterrupted production without human intervention. Explore how advanced planned maintenance strategies optimize both TPM and lights out factory performance.

Source and External Links

TPM Meaning: Components, Benefits, & More - UpKeep - Total Productive Maintenance (TPM) is a process that maximizes equipment effectiveness through involvement from all departments, aiming to eliminate losses from poor maintenance and achieve near-perfect production by using preventive, autonomous, and corrective maintenance practices.

TPM (Total Productive Maintenance) - TPM is a holistic approach that emphasizes proactive and preventive maintenance, blurs the line between production and maintenance roles by empowering operators, and is built on 5S principles and eight supporting activities to improve equipment reliability and workplace safety.

Lean Thinking and Methods - TPM - TPM seeks company-wide engagement to maximize production equipment effectiveness by preventing breakdowns, eliminating defects, involving workers in autonomous maintenance, and targeting zero equipment breakdowns and defects through total loss elimination strategies.

dowidth.com

dowidth.com