Industrial internet integrates advanced sensors and IoT devices to enable real-time data collection and analysis in manufacturing environments, enhancing operational efficiency. Predictive maintenance leverages this data through machine learning algorithms to forecast equipment failures and schedule timely interventions, reducing downtime and maintenance costs. Explore how combining industrial internet with predictive maintenance transforms manufacturing productivity and reliability.

Why it is important

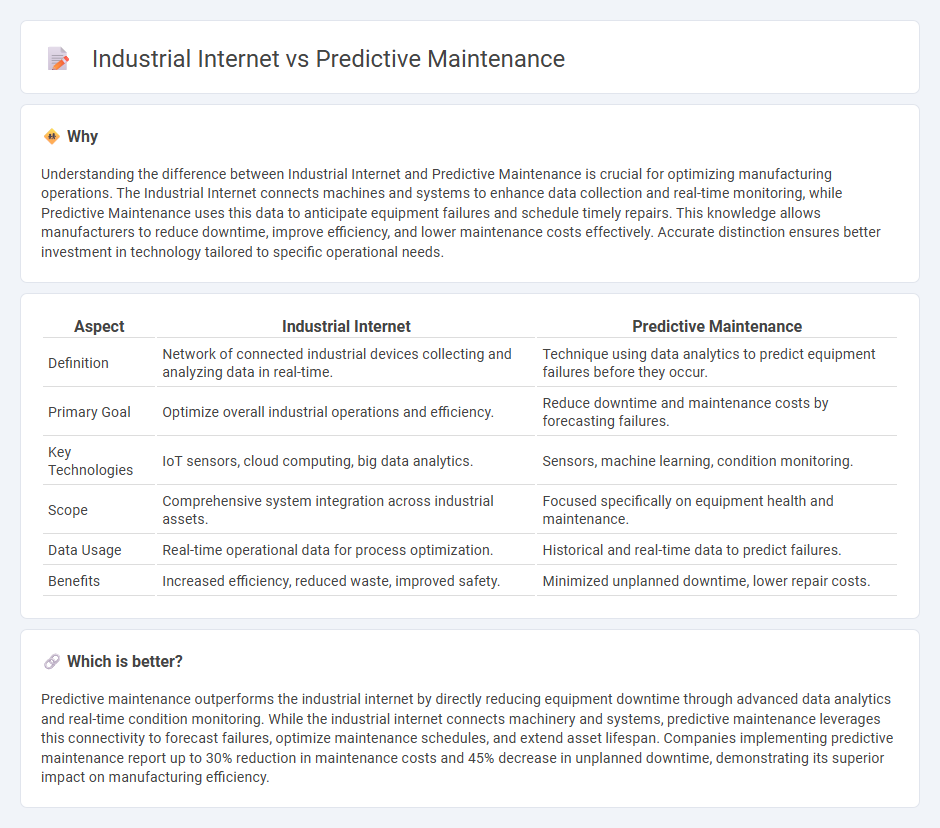

Understanding the difference between Industrial Internet and Predictive Maintenance is crucial for optimizing manufacturing operations. The Industrial Internet connects machines and systems to enhance data collection and real-time monitoring, while Predictive Maintenance uses this data to anticipate equipment failures and schedule timely repairs. This knowledge allows manufacturers to reduce downtime, improve efficiency, and lower maintenance costs effectively. Accurate distinction ensures better investment in technology tailored to specific operational needs.

Comparison Table

| Aspect | Industrial Internet | Predictive Maintenance |

|---|---|---|

| Definition | Network of connected industrial devices collecting and analyzing data in real-time. | Technique using data analytics to predict equipment failures before they occur. |

| Primary Goal | Optimize overall industrial operations and efficiency. | Reduce downtime and maintenance costs by forecasting failures. |

| Key Technologies | IoT sensors, cloud computing, big data analytics. | Sensors, machine learning, condition monitoring. |

| Scope | Comprehensive system integration across industrial assets. | Focused specifically on equipment health and maintenance. |

| Data Usage | Real-time operational data for process optimization. | Historical and real-time data to predict failures. |

| Benefits | Increased efficiency, reduced waste, improved safety. | Minimized unplanned downtime, lower repair costs. |

Which is better?

Predictive maintenance outperforms the industrial internet by directly reducing equipment downtime through advanced data analytics and real-time condition monitoring. While the industrial internet connects machinery and systems, predictive maintenance leverages this connectivity to forecast failures, optimize maintenance schedules, and extend asset lifespan. Companies implementing predictive maintenance report up to 30% reduction in maintenance costs and 45% decrease in unplanned downtime, demonstrating its superior impact on manufacturing efficiency.

Connection

Industrial Internet of Things (IIoT) enables real-time data collection from manufacturing equipment, which predictive maintenance leverages to forecast machine failures and optimize maintenance schedules. By integrating sensors and connectivity, IIoT enhances the accuracy of predictive algorithms, reducing downtime and maintenance costs. This synergy improves overall equipment effectiveness (OEE) and supports smart factory initiatives.

Key Terms

Sensors

Sensors play a crucial role in predictive maintenance by continuously monitoring equipment conditions such as vibration, temperature, and pressure to detect anomalies before failures occur. In the industrial internet landscape, sensors enable real-time connectivity and data exchange across machines, enhancing process automation and operational efficiency. Explore how integrating advanced sensor technologies transforms industrial maintenance strategies and boosts productivity.

Machine Learning

Predictive maintenance leverages machine learning algorithms to analyze sensor data and predict equipment failures before they occur, reducing downtime and maintenance costs. The industrial internet integrates these predictive capabilities by connecting machines through IoT networks, enabling real-time data collection and advanced analytics for smarter decision-making. Discover how combining machine learning with the industrial internet transforms maintenance strategies and operational efficiency.

Connectivity

Predictive maintenance relies heavily on connectivity within the industrial internet of things (IIoT) to collect real-time sensor data and monitor equipment health, enabling proactive repairs before failures occur. Industrial internet platforms enhance connectivity by integrating diverse machines, systems, and networks through advanced protocols such as MQTT and OPC UA, ensuring seamless data flow for predictive analytics. Explore how connectivity innovations are transforming predictive maintenance effectiveness and industrial operations by diving deeper into IIoT developments.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses sensor data and machine learning to predict equipment health and optimize maintenance timing, reducing costs and downtime by performing maintenance only when necessary.

Predictive maintenance - Wikipedia - Predictive maintenance techniques estimate equipment condition to optimize maintenance scheduling, aiming to prevent unexpected failures and increase equipment lifespan using real-time data and machine learning.

Predictive Maintenance: An Easy Guide | SafetyCulture - Predictive maintenance involves collecting real-time data via sensors, processing it with machine learning algorithms to forecast failures, and scheduling maintenance just before equipment failure.

dowidth.com

dowidth.com