Process mining in manufacturing leverages event data from production systems to analyze and optimize workflows, identifying bottlenecks and inefficiencies in real-time. Enterprise Resource Planning (ERP) systems integrate core business processes such as inventory management, procurement, and scheduling, providing comprehensive resource planning and operational control. Explore deeper insights into how process mining complements ERP to enhance manufacturing efficiency and decision-making.

Why it is important

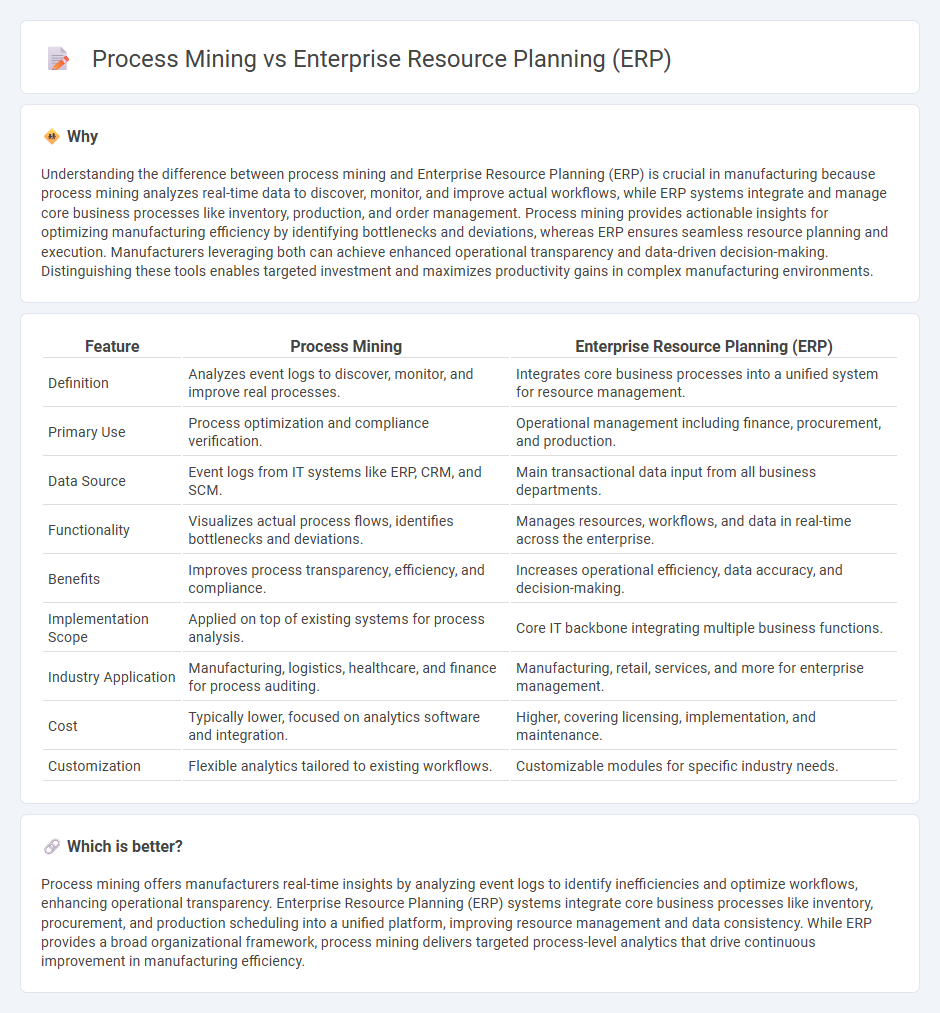

Understanding the difference between process mining and Enterprise Resource Planning (ERP) is crucial in manufacturing because process mining analyzes real-time data to discover, monitor, and improve actual workflows, while ERP systems integrate and manage core business processes like inventory, production, and order management. Process mining provides actionable insights for optimizing manufacturing efficiency by identifying bottlenecks and deviations, whereas ERP ensures seamless resource planning and execution. Manufacturers leveraging both can achieve enhanced operational transparency and data-driven decision-making. Distinguishing these tools enables targeted investment and maximizes productivity gains in complex manufacturing environments.

Comparison Table

| Feature | Process Mining | Enterprise Resource Planning (ERP) |

|---|---|---|

| Definition | Analyzes event logs to discover, monitor, and improve real processes. | Integrates core business processes into a unified system for resource management. |

| Primary Use | Process optimization and compliance verification. | Operational management including finance, procurement, and production. |

| Data Source | Event logs from IT systems like ERP, CRM, and SCM. | Main transactional data input from all business departments. |

| Functionality | Visualizes actual process flows, identifies bottlenecks and deviations. | Manages resources, workflows, and data in real-time across the enterprise. |

| Benefits | Improves process transparency, efficiency, and compliance. | Increases operational efficiency, data accuracy, and decision-making. |

| Implementation Scope | Applied on top of existing systems for process analysis. | Core IT backbone integrating multiple business functions. |

| Industry Application | Manufacturing, logistics, healthcare, and finance for process auditing. | Manufacturing, retail, services, and more for enterprise management. |

| Cost | Typically lower, focused on analytics software and integration. | Higher, covering licensing, implementation, and maintenance. |

| Customization | Flexible analytics tailored to existing workflows. | Customizable modules for specific industry needs. |

Which is better?

Process mining offers manufacturers real-time insights by analyzing event logs to identify inefficiencies and optimize workflows, enhancing operational transparency. Enterprise Resource Planning (ERP) systems integrate core business processes like inventory, procurement, and production scheduling into a unified platform, improving resource management and data consistency. While ERP provides a broad organizational framework, process mining delivers targeted process-level analytics that drive continuous improvement in manufacturing efficiency.

Connection

Process mining enhances Enterprise Resource Planning (ERP) systems by extracting actionable insights from event logs generated during manufacturing operations, enabling detailed analysis of workflow efficiency and bottlenecks. Integrating process mining with ERP facilitates real-time monitoring and optimization of production processes, improving resource allocation and reducing operational costs. This synergy supports data-driven decision-making in manufacturing by aligning process execution with strategic business goals.

Key Terms

Integration

Enterprise Resource Planning (ERP) systems centralize business processes into a unified software platform, optimizing resource allocation and data consistency across departments. Process mining leverages event logs from ERP and other IT systems to analyze, visualize, and improve actual workflows by discovering inefficiencies or deviations from designed processes. Explore how integrating ERP with process mining tools can maximize operational transparency and decision-making efficiency.

Automation

Enterprise Resource Planning (ERP) systems integrate core business processes into a unified platform, automating workflows such as inventory management, finance, and human resources to enhance operational efficiency. Process mining leverages data analytics to visualize, analyze, and optimize actual business processes, identifying automation opportunities and bottlenecks based on real-time event logs. Explore how combining ERP with process mining can drive advanced automation and transform your enterprise operations.

Data Analysis

ERP systems centralize business data, enabling efficient resource planning and operational management through structured data analysis. Process mining extracts and visualizes real-time process information from event logs, uncovering inefficiencies and optimizing workflows beyond traditional ERP reporting. Explore how integrating ERP data with process mining can revolutionize enterprise data analysis strategies.

Source and External Links

Enterprise resource planning - Wikipedia - ERP is the integrated management of main business processes, often in real time and mediated by software that helps organizations collect, store, manage, and interpret data across various departments.

What is Enterprise Resource Planning (ERP)? - IBM - ERP is a business management software system designed to manage, streamline, and automate an organization's functions, processes, and workflows using connected modules and a shared database.

What is ERP? A Comprehensive Guide - NetSuite - ERP is a category of business software that automates processes, provides insights and controls, and centralizes data from accounting, manufacturing, supply chain, sales, marketing, and HR to improve efficiency and visibility.

dowidth.com

dowidth.com