Lights out factories operate fully automated production lines without human intervention, significantly reducing labor costs and minimizing errors. Continuous manufacturing involves uninterrupted production processes that enhance efficiency and maintain consistent product quality through real-time monitoring and control. Discover how these advanced manufacturing methods revolutionize industrial productivity and operational excellence.

Why it is important

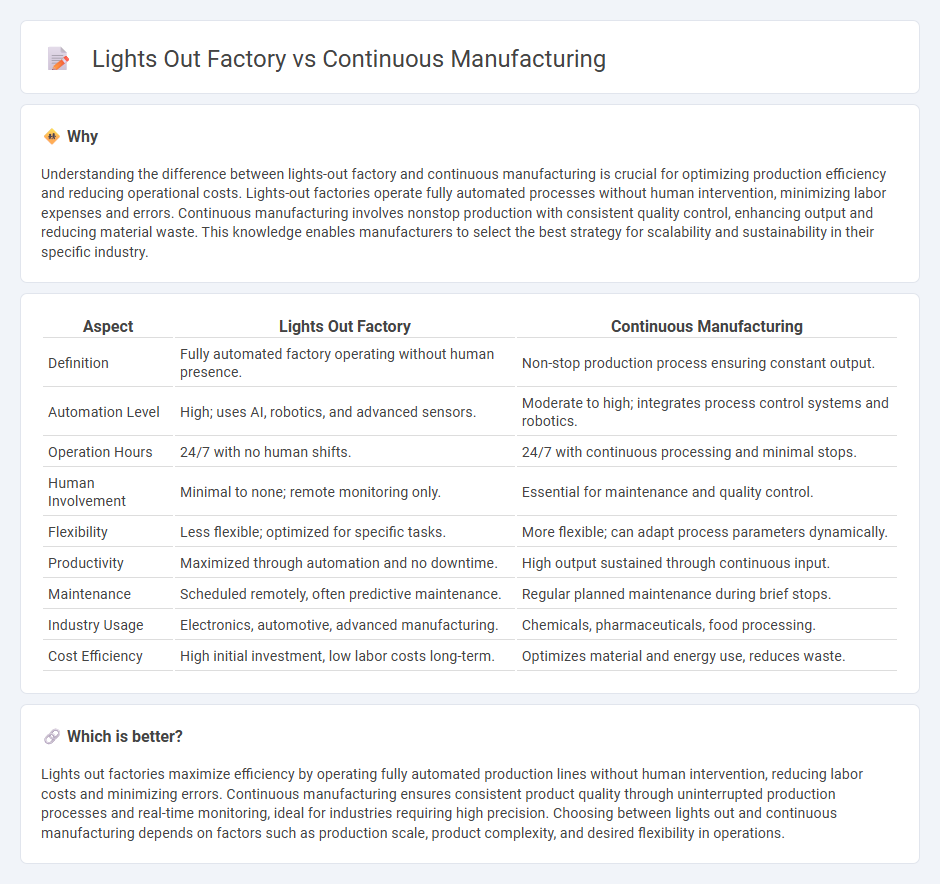

Understanding the difference between lights-out factory and continuous manufacturing is crucial for optimizing production efficiency and reducing operational costs. Lights-out factories operate fully automated processes without human intervention, minimizing labor expenses and errors. Continuous manufacturing involves nonstop production with consistent quality control, enhancing output and reducing material waste. This knowledge enables manufacturers to select the best strategy for scalability and sustainability in their specific industry.

Comparison Table

| Aspect | Lights Out Factory | Continuous Manufacturing |

|---|---|---|

| Definition | Fully automated factory operating without human presence. | Non-stop production process ensuring constant output. |

| Automation Level | High; uses AI, robotics, and advanced sensors. | Moderate to high; integrates process control systems and robotics. |

| Operation Hours | 24/7 with no human shifts. | 24/7 with continuous processing and minimal stops. |

| Human Involvement | Minimal to none; remote monitoring only. | Essential for maintenance and quality control. |

| Flexibility | Less flexible; optimized for specific tasks. | More flexible; can adapt process parameters dynamically. |

| Productivity | Maximized through automation and no downtime. | High output sustained through continuous input. |

| Maintenance | Scheduled remotely, often predictive maintenance. | Regular planned maintenance during brief stops. |

| Industry Usage | Electronics, automotive, advanced manufacturing. | Chemicals, pharmaceuticals, food processing. |

| Cost Efficiency | High initial investment, low labor costs long-term. | Optimizes material and energy use, reduces waste. |

Which is better?

Lights out factories maximize efficiency by operating fully automated production lines without human intervention, reducing labor costs and minimizing errors. Continuous manufacturing ensures consistent product quality through uninterrupted production processes and real-time monitoring, ideal for industries requiring high precision. Choosing between lights out and continuous manufacturing depends on factors such as production scale, product complexity, and desired flexibility in operations.

Connection

Lights out factories operate without human presence, relying heavily on automated systems that enable continuous manufacturing processes to run 24/7 without interruption. This seamless integration of robotics, IoT devices, and advanced software ensures consistent production quality, higher efficiency, and reduced operational costs. Continuous manufacturing leverages the lights out factory model to maximize output while minimizing downtime and human error.

Key Terms

Automation

Continuous manufacturing employs automated processes that enable uninterrupted production, reducing human intervention and improving efficiency. Lights-out factories utilize full automation and robotics to operate entirely without onsite personnel, maximizing operational uptime and minimizing labor costs. Explore how advanced automation technologies are transforming manufacturing by delving deeper into continuous manufacturing and lights-out factory systems.

Real-time Monitoring

Continuous manufacturing utilizes real-time monitoring to ensure consistent product quality and operational efficiency by integrating advanced sensors and data analytics throughout the production line. Lights out factories employ autonomous systems with real-time monitoring to enable fully automated production without human intervention, maximizing uptime and reducing labor costs. Explore the latest innovations in real-time monitoring technology to understand how these manufacturing paradigms are transforming industrial processes.

Human Intervention

Continuous manufacturing reduces human intervention by automating production processes to maintain consistent quality and efficiency, while lights-out factories operate entirely without human presence, leveraging full automation and advanced robotics for 24/7 operations. The key distinction lies in the degree of human involvement: continuous manufacturing still requires skilled operators for monitoring and troubleshooting, whereas lights-out factories rely solely on automated systems. Explore more about the benefits and challenges of minimizing human intervention in modern manufacturing environments.

Source and External Links

Continuous Manufacturing and How To Do It - Katana Cloud Inventory - Continuous manufacturing is a 24/7 production method where raw materials flow through one continuous process in one location, allowing ongoing evaluation and improvement, widely used in industries like oil refining and pharmaceuticals to minimize waste and cost.

Continuous production - Wikipedia - Continuous production is a flow manufacturing method running non-stop with materials always in motion undergoing processing, typically operating 24/7 with infrequent shutdowns, contrasting batch production.

The Power of Continuous Manufacturing Explained - YouTube - Continuous manufacturing produces goods through a nonstop, end-to-end process, maximizing output and quality by reducing human error and shortening production cycles compared to batch manufacturing.

dowidth.com

dowidth.com