Manufacturing efficiency dramatically increases when collaborative robots (cobots) work alongside humans, combining automation precision with human creativity and adaptability. Cobots excel in repetitive, high-accuracy tasks, while human workers manage complex decision-making and problem-solving activities, enhancing overall productivity. Explore how integrating cobotics with human labor transforms modern manufacturing processes for greater innovation and output.

Why it is important

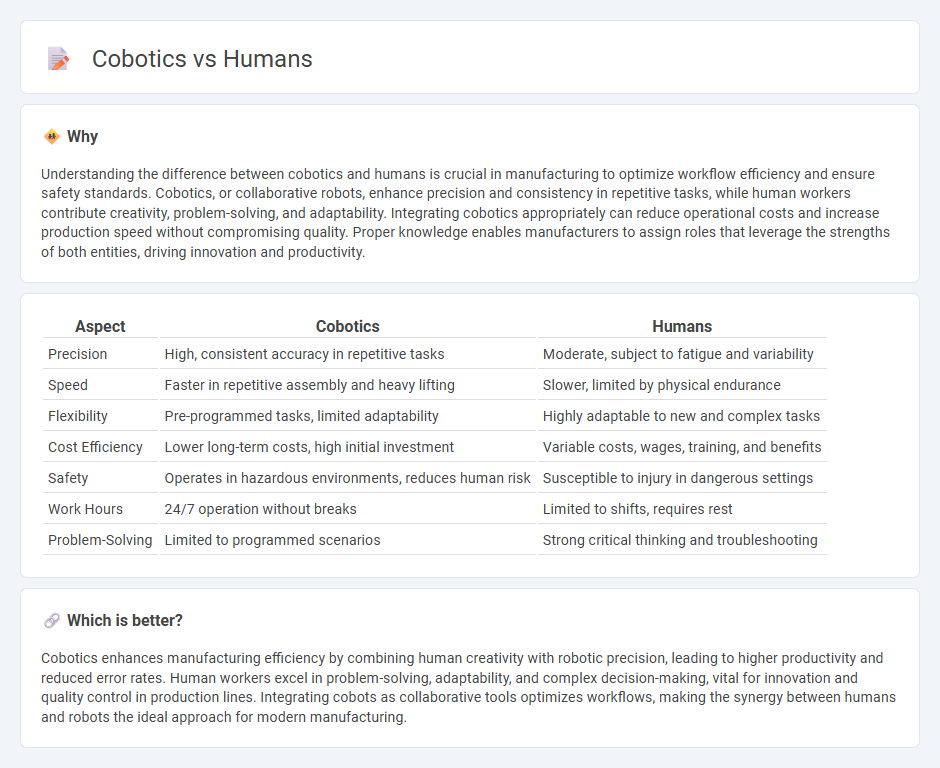

Understanding the difference between cobotics and humans is crucial in manufacturing to optimize workflow efficiency and ensure safety standards. Cobotics, or collaborative robots, enhance precision and consistency in repetitive tasks, while human workers contribute creativity, problem-solving, and adaptability. Integrating cobotics appropriately can reduce operational costs and increase production speed without compromising quality. Proper knowledge enables manufacturers to assign roles that leverage the strengths of both entities, driving innovation and productivity.

Comparison Table

| Aspect | Cobotics | Humans |

|---|---|---|

| Precision | High, consistent accuracy in repetitive tasks | Moderate, subject to fatigue and variability |

| Speed | Faster in repetitive assembly and heavy lifting | Slower, limited by physical endurance |

| Flexibility | Pre-programmed tasks, limited adaptability | Highly adaptable to new and complex tasks |

| Cost Efficiency | Lower long-term costs, high initial investment | Variable costs, wages, training, and benefits |

| Safety | Operates in hazardous environments, reduces human risk | Susceptible to injury in dangerous settings |

| Work Hours | 24/7 operation without breaks | Limited to shifts, requires rest |

| Problem-Solving | Limited to programmed scenarios | Strong critical thinking and troubleshooting |

Which is better?

Cobotics enhances manufacturing efficiency by combining human creativity with robotic precision, leading to higher productivity and reduced error rates. Human workers excel in problem-solving, adaptability, and complex decision-making, vital for innovation and quality control in production lines. Integrating cobots as collaborative tools optimizes workflows, making the synergy between humans and robots the ideal approach for modern manufacturing.

Connection

Cobotics integrates human workers with collaborative robots designed to work safely alongside them, enhancing manufacturing efficiency and precision. These robots support repetitive or physically demanding tasks, allowing human operators to focus on complex decision-making and quality control. The synergy between cobots and humans drives productivity improvements and enables adaptive, flexible production systems in modern factories.

Key Terms

Collaboration

Humans and cobotics work synergistically to enhance productivity by combining human creativity and problem-solving with robotic precision and endurance. Cobots are designed for safe, intuitive interaction within shared workspaces, enabling seamless collaboration that reduces errors and increases efficiency. Explore how this innovative partnership is transforming industries and redefining the future of work.

Safety

Human-robot collaboration (cobotics) enhances workplace efficiency but requires rigorous safety protocols to protect human workers. Advanced sensors, real-time monitoring systems, and fail-safe mechanisms minimize risks and ensure compliance with safety standards such as ISO 10218 and ISO/TS 15066. Explore cutting-edge safety measures in cobotics to safeguard human-machine interactions effectively.

Task Allocation

Task allocation in humans versus cobotics involves assigning responsibilities based on capabilities, with humans excelling in complex decision-making and adaptability while cobots handle repetitive, precise tasks efficiently. Effective collaboration optimizes productivity by leveraging human intuition and robotic consistency in manufacturing, healthcare, and logistics. Explore how strategic task allocation enhances synergy between human workers and collaborative robots for future industry advancements.

Source and External Links

Human - Wikipedia - Humans (Homo sapiens) are the most common and widespread primate species, characterized by bipedalism, large brains, advanced cognition, complex social structures, and the development of civilizations with over 8 billion individuals alive as of 2025.

Humans (TV series) - Wikipedia - "Humans" is a science fiction TV series exploring the impact of anthropomorphic robots called "synths" on society, covering themes like artificial intelligence and human-robot interaction.

HUMANS.uz - HUMANS is a platform offering mobile services that range from free to unlimited, designed for savvy users seeking discounts and cashback in one app.

dowidth.com

dowidth.com