Condition-based monitoring leverages real-time data from sensors to detect equipment anomalies and prevent unexpected failures, enhancing operational efficiency and reducing downtime costs. Total productive maintenance integrates proactive and preventive maintenance techniques, involving all employees to maximize equipment effectiveness and extend asset life. Explore how these maintenance strategies can transform manufacturing productivity and reliability.

Why it is important

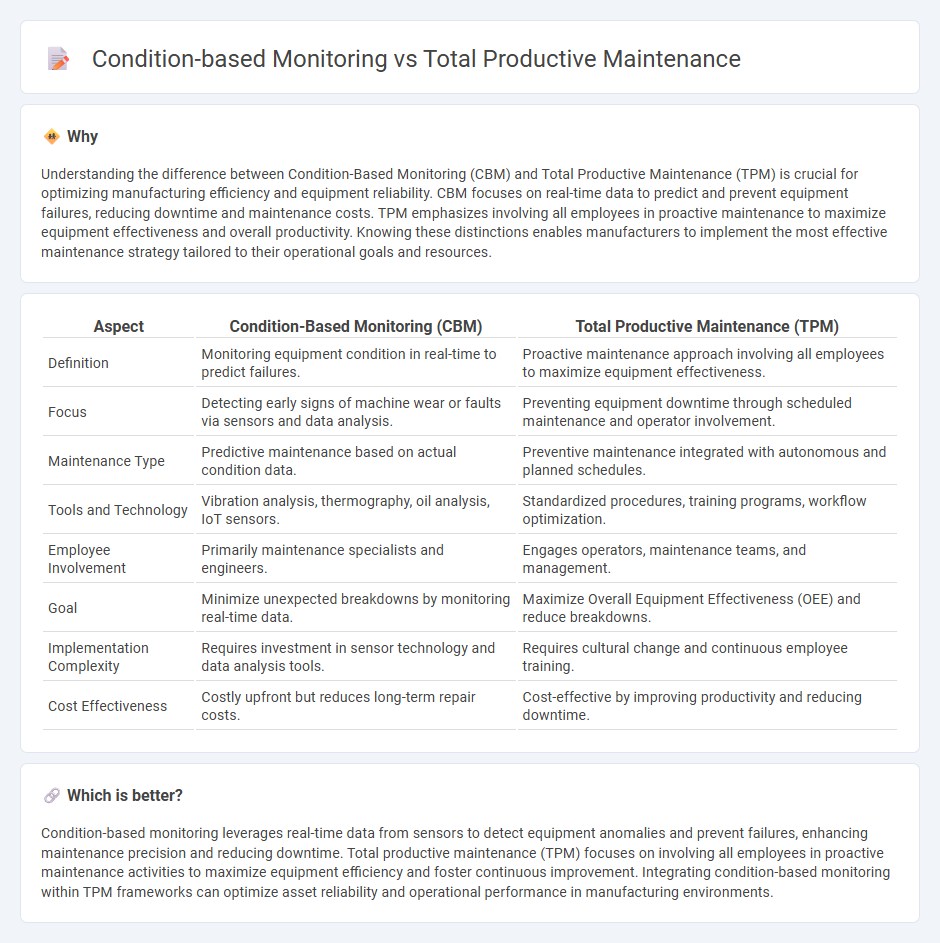

Understanding the difference between Condition-Based Monitoring (CBM) and Total Productive Maintenance (TPM) is crucial for optimizing manufacturing efficiency and equipment reliability. CBM focuses on real-time data to predict and prevent equipment failures, reducing downtime and maintenance costs. TPM emphasizes involving all employees in proactive maintenance to maximize equipment effectiveness and overall productivity. Knowing these distinctions enables manufacturers to implement the most effective maintenance strategy tailored to their operational goals and resources.

Comparison Table

| Aspect | Condition-Based Monitoring (CBM) | Total Productive Maintenance (TPM) |

|---|---|---|

| Definition | Monitoring equipment condition in real-time to predict failures. | Proactive maintenance approach involving all employees to maximize equipment effectiveness. |

| Focus | Detecting early signs of machine wear or faults via sensors and data analysis. | Preventing equipment downtime through scheduled maintenance and operator involvement. |

| Maintenance Type | Predictive maintenance based on actual condition data. | Preventive maintenance integrated with autonomous and planned schedules. |

| Tools and Technology | Vibration analysis, thermography, oil analysis, IoT sensors. | Standardized procedures, training programs, workflow optimization. |

| Employee Involvement | Primarily maintenance specialists and engineers. | Engages operators, maintenance teams, and management. |

| Goal | Minimize unexpected breakdowns by monitoring real-time data. | Maximize Overall Equipment Effectiveness (OEE) and reduce breakdowns. |

| Implementation Complexity | Requires investment in sensor technology and data analysis tools. | Requires cultural change and continuous employee training. |

| Cost Effectiveness | Costly upfront but reduces long-term repair costs. | Cost-effective by improving productivity and reducing downtime. |

Which is better?

Condition-based monitoring leverages real-time data from sensors to detect equipment anomalies and prevent failures, enhancing maintenance precision and reducing downtime. Total productive maintenance (TPM) focuses on involving all employees in proactive maintenance activities to maximize equipment efficiency and foster continuous improvement. Integrating condition-based monitoring within TPM frameworks can optimize asset reliability and operational performance in manufacturing environments.

Connection

Condition-based monitoring (CBM) enhances Total Productive Maintenance (TPM) by providing real-time data on equipment health, enabling predictive maintenance activities that reduce unexpected downtime. TPM focuses on maximizing equipment effectiveness through proactive and preventive measures, where CBM supplies critical insights to optimize maintenance scheduling and resource allocation. Integrating CBM within TPM frameworks leads to increased machinery reliability, improved production efficiency, and extended asset lifecycle.

Key Terms

**Total Productive Maintenance:**

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance involving all employees to maximize equipment effectiveness and minimize downtime. It integrates autonomous maintenance by operators, planned maintenance schedules, and continuous improvement activities to enhance overall equipment productivity. Explore how TPM implementation transforms asset management and boosts operational efficiency.

Autonomous Maintenance

Total Productive Maintenance (TPM) emphasizes autonomous maintenance by empowering operators to perform routine inspections, cleaning, and minor repairs, enhancing equipment reliability and reducing downtime. Condition-Based Monitoring (CBM) relies on real-time sensor data to predict equipment failures and optimize maintenance schedules based on actual machinery conditions. Explore how integrating autonomous maintenance in TPM complements CBM strategies for a holistic approach to operational excellence.

Planned Maintenance

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance involving all employees to maximize equipment efficiency and reduce downtime through planned maintenance activities. Condition-Based Monitoring (CBM) leverages real-time data from sensors to predict equipment failures, allowing targeted planned maintenance intervention only when necessary. Explore how integrating TPM with CBM can optimize your planned maintenance strategies for enhanced operational performance.

Source and External Links

TPM Meaning: Components, Benefits, & More - Total Productive Maintenance (TPM) aims to maximize equipment effectiveness by involving all departments in maintenance processes to eliminate production losses.

TPM (Total Productive Maintenance) - TPM is a holistic approach to equipment maintenance that emphasizes proactive and preventative maintenance to achieve perfect production while ensuring a safe working environment.

Total Productive Maintenance: An Overview - TPM uses machines, equipment, employees, and processes to maintain and improve production integrity, focusing on proactive maintenance to prevent breakdowns and defects.

dowidth.com

dowidth.com