Machine vision systems utilize advanced cameras and image processing to inspect and analyze products with high precision, enhancing quality control in manufacturing processes. SCADA systems provide real-time monitoring and control of industrial equipment, enabling efficient management of production workflows and minimizing downtime. Explore how integrating machine vision with SCADA can revolutionize manufacturing operations.

Why it is important

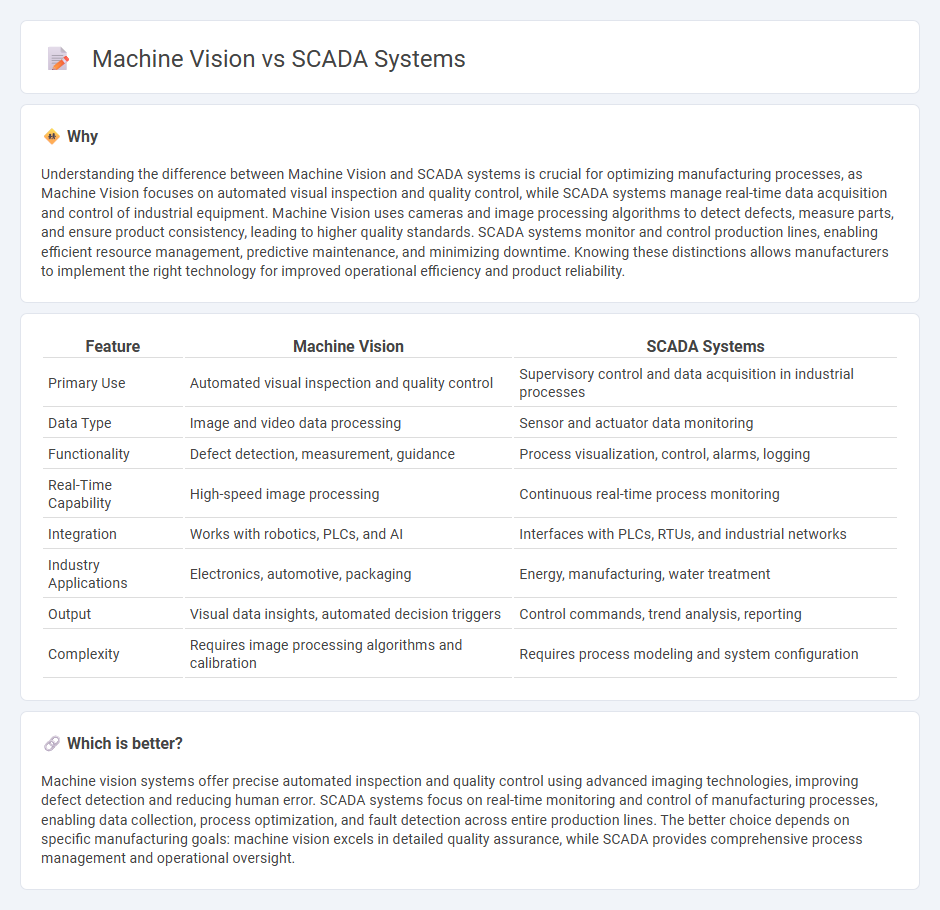

Understanding the difference between Machine Vision and SCADA systems is crucial for optimizing manufacturing processes, as Machine Vision focuses on automated visual inspection and quality control, while SCADA systems manage real-time data acquisition and control of industrial equipment. Machine Vision uses cameras and image processing algorithms to detect defects, measure parts, and ensure product consistency, leading to higher quality standards. SCADA systems monitor and control production lines, enabling efficient resource management, predictive maintenance, and minimizing downtime. Knowing these distinctions allows manufacturers to implement the right technology for improved operational efficiency and product reliability.

Comparison Table

| Feature | Machine Vision | SCADA Systems |

|---|---|---|

| Primary Use | Automated visual inspection and quality control | Supervisory control and data acquisition in industrial processes |

| Data Type | Image and video data processing | Sensor and actuator data monitoring |

| Functionality | Defect detection, measurement, guidance | Process visualization, control, alarms, logging |

| Real-Time Capability | High-speed image processing | Continuous real-time process monitoring |

| Integration | Works with robotics, PLCs, and AI | Interfaces with PLCs, RTUs, and industrial networks |

| Industry Applications | Electronics, automotive, packaging | Energy, manufacturing, water treatment |

| Output | Visual data insights, automated decision triggers | Control commands, trend analysis, reporting |

| Complexity | Requires image processing algorithms and calibration | Requires process modeling and system configuration |

Which is better?

Machine vision systems offer precise automated inspection and quality control using advanced imaging technologies, improving defect detection and reducing human error. SCADA systems focus on real-time monitoring and control of manufacturing processes, enabling data collection, process optimization, and fault detection across entire production lines. The better choice depends on specific manufacturing goals: machine vision excels in detailed quality assurance, while SCADA provides comprehensive process management and operational oversight.

Connection

Machine vision systems enhance manufacturing processes by capturing real-time visual data used for quality control and defect detection. SCADA systems integrate this visual data to monitor and control production lines, enabling automated decision-making and operational efficiency. The synergy between machine vision and SCADA facilitates precise process control, reduces downtime, and improves overall equipment effectiveness (OEE).

Key Terms

Real-time Monitoring (SCADA)

SCADA systems specialize in real-time monitoring by continuously collecting and analyzing data from industrial processes to ensure operational efficiency and rapid fault detection. Machine vision focuses on image-based inspection and quality control but lacks the comprehensive sensor integration and event-driven alerts characteristic of SCADA. Explore the detailed differences and applications to enhance your industrial automation strategy.

Image Processing (Machine Vision)

Machine vision systems utilize advanced image processing techniques such as pattern recognition, edge detection, and 3D imaging to automate inspection and quality control tasks, offering high precision and real-time analysis. SCADA systems primarily focus on supervisory control and data acquisition across industrial processes but lack the specialized image processing capabilities inherent in machine vision. Explore further the transformative impact of machine vision technology on industrial automation and process optimization.

Automation Control

SCADA systems excel in real-time automation control by monitoring and managing industrial processes through sensors and actuators, ensuring system stability and efficiency. Machine vision enhances automation by providing precise visual inspection, defect detection, and quality control, enabling intelligent decision-making based on image analysis. Explore how integrating SCADA with machine vision can optimize production workflows and elevate automation performance.

Source and External Links

What is SCADA system and how does it work? - AVEVA - SCADA systems combine software and hardware to automate industrial processes, allowing organizations to monitor, control, and optimize equipment and operations in real time.

SCADA - Wikipedia - SCADA is a control system architecture using computers, networked communications, and graphical interfaces to supervise and manage industrial processes and infrastructure across multiple locations.

What is SCADA? Supervisory Control and Data Acquisition - SCADA systems enable organizations to control, monitor, and log industrial processes by interfacing directly with machinery and providing real-time data visualization through HMIs.

dowidth.com

dowidth.com