Digital twinning creates a virtual replica of a physical asset or process, enabling real-time monitoring and simulation to enhance manufacturing efficiency. Digital thread integrates data flow across the entire product lifecycle, ensuring seamless connectivity and traceability from design to production and maintenance. Discover how leveraging digital twinning and digital thread can transform manufacturing operations.

Why it is important

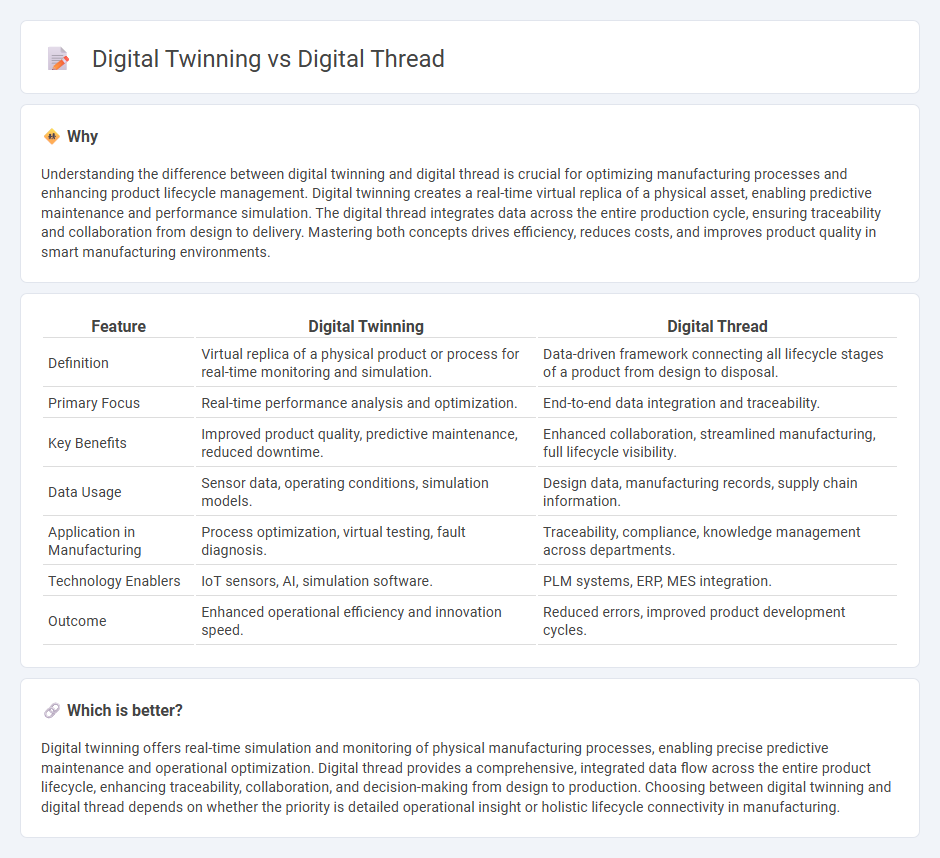

Understanding the difference between digital twinning and digital thread is crucial for optimizing manufacturing processes and enhancing product lifecycle management. Digital twinning creates a real-time virtual replica of a physical asset, enabling predictive maintenance and performance simulation. The digital thread integrates data across the entire production cycle, ensuring traceability and collaboration from design to delivery. Mastering both concepts drives efficiency, reduces costs, and improves product quality in smart manufacturing environments.

Comparison Table

| Feature | Digital Twinning | Digital Thread |

|---|---|---|

| Definition | Virtual replica of a physical product or process for real-time monitoring and simulation. | Data-driven framework connecting all lifecycle stages of a product from design to disposal. |

| Primary Focus | Real-time performance analysis and optimization. | End-to-end data integration and traceability. |

| Key Benefits | Improved product quality, predictive maintenance, reduced downtime. | Enhanced collaboration, streamlined manufacturing, full lifecycle visibility. |

| Data Usage | Sensor data, operating conditions, simulation models. | Design data, manufacturing records, supply chain information. |

| Application in Manufacturing | Process optimization, virtual testing, fault diagnosis. | Traceability, compliance, knowledge management across departments. |

| Technology Enablers | IoT sensors, AI, simulation software. | PLM systems, ERP, MES integration. |

| Outcome | Enhanced operational efficiency and innovation speed. | Reduced errors, improved product development cycles. |

Which is better?

Digital twinning offers real-time simulation and monitoring of physical manufacturing processes, enabling precise predictive maintenance and operational optimization. Digital thread provides a comprehensive, integrated data flow across the entire product lifecycle, enhancing traceability, collaboration, and decision-making from design to production. Choosing between digital twinning and digital thread depends on whether the priority is detailed operational insight or holistic lifecycle connectivity in manufacturing.

Connection

Digital twinning creates a real-time virtual replica of physical manufacturing assets, enabling precise simulation and analysis. The digital thread links all data and processes across the product lifecycle, from design to production and maintenance, ensuring continuous data flow. Together, digital twin and digital thread enhance manufacturing efficiency, reduce downtime, and improve product quality through integrated, data-driven insights.

Key Terms

Data Integration

The digital thread provides a seamless data integration framework that connects all stages of a product's lifecycle, ensuring continuous data flow and traceability across design, manufacturing, and maintenance. Digital twinning, on the other hand, creates dynamic, real-time virtual replicas of physical assets using integrated data for simulation and performance analysis. Explore how leveraging these technologies can enhance product development and operational efficiency.

Real-time Monitoring

Digital thread integrates data across the product lifecycle, enabling seamless traceability and collaboration from design to manufacturing and service. Digital twins create real-time virtual replicas of physical assets, allowing continuous monitoring and predictive maintenance through sensor data. Explore how real-time monitoring enhances operational efficiency by combining digital thread and digital twinning technologies.

Lifecycle Management

Digital thread integrates data from design, manufacturing, and service phases into a continuous, traceable lifecycle record, enhancing product lifecycle management (PLM) and enabling real-time decision-making. Digital twinning creates a virtual replica of a physical asset or system, facilitating simulation, monitoring, and predictive maintenance throughout the product lifecycle. Explore how combining digital thread and digital twinning optimizes lifecycle management and drives operational excellence.

Source and External Links

Digital thread - Wikipedia - The digital thread is a data-driven architecture linking information from all stages of a product lifecycle across distributed manufacturing systems, enabling seamless data integration for real-time decision-making and iteration.

A digital thread What it is and why you need it - AVEVA - A digital thread is the continuous digital flow of data and information connected across multiple points such as systems, devices, or people, providing trustworthy, consistent information accessible to all stakeholders.

Definition of Digital Thread - Digital Twin Consortium - The digital thread is a bidirectional, interconnected information system uniting multiple dimensions and lifecycle stages to ensure secure data exchange and enable dynamic, real-time insights that support decision-making and operational optimization.

dowidth.com

dowidth.com