Digital thread integrates real-time data and analytics across the entire manufacturing lifecycle, enhancing traceability and decision-making from design to production. SCADA focuses on monitoring and controlling industrial processes by collecting data from sensors and equipment to ensure operational efficiency and safety. Explore the benefits and differences between Digital Thread and SCADA to optimize manufacturing performance.

Why it is important

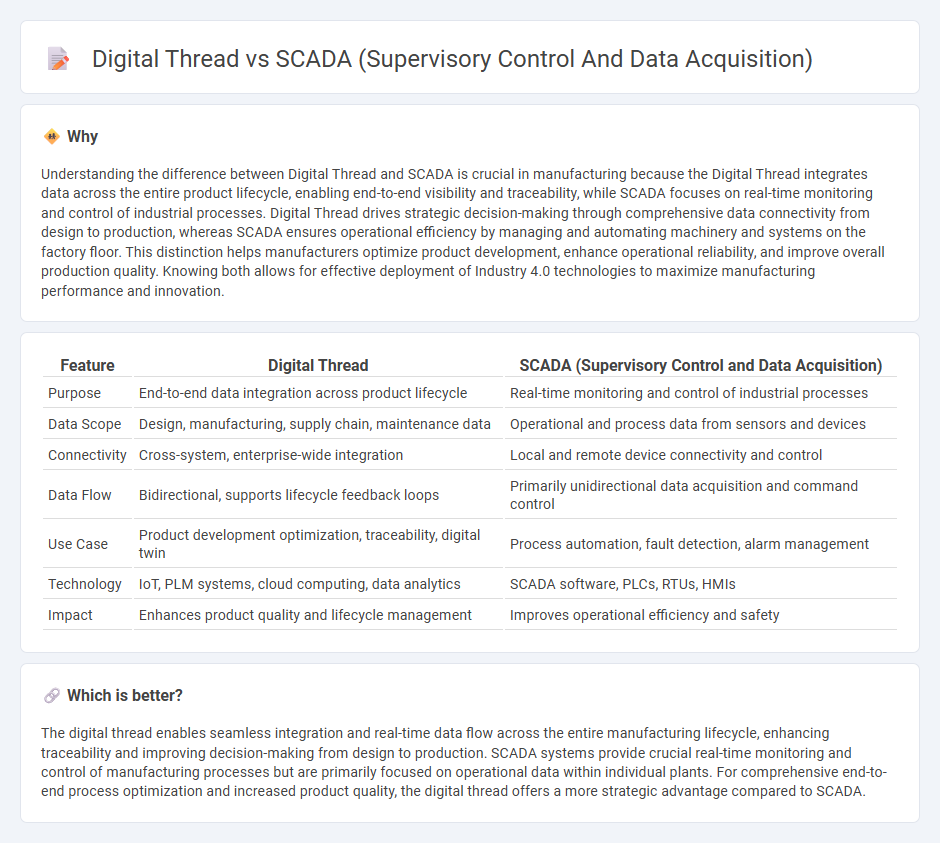

Understanding the difference between Digital Thread and SCADA is crucial in manufacturing because the Digital Thread integrates data across the entire product lifecycle, enabling end-to-end visibility and traceability, while SCADA focuses on real-time monitoring and control of industrial processes. Digital Thread drives strategic decision-making through comprehensive data connectivity from design to production, whereas SCADA ensures operational efficiency by managing and automating machinery and systems on the factory floor. This distinction helps manufacturers optimize product development, enhance operational reliability, and improve overall production quality. Knowing both allows for effective deployment of Industry 4.0 technologies to maximize manufacturing performance and innovation.

Comparison Table

| Feature | Digital Thread | SCADA (Supervisory Control and Data Acquisition) |

|---|---|---|

| Purpose | End-to-end data integration across product lifecycle | Real-time monitoring and control of industrial processes |

| Data Scope | Design, manufacturing, supply chain, maintenance data | Operational and process data from sensors and devices |

| Connectivity | Cross-system, enterprise-wide integration | Local and remote device connectivity and control |

| Data Flow | Bidirectional, supports lifecycle feedback loops | Primarily unidirectional data acquisition and command control |

| Use Case | Product development optimization, traceability, digital twin | Process automation, fault detection, alarm management |

| Technology | IoT, PLM systems, cloud computing, data analytics | SCADA software, PLCs, RTUs, HMIs |

| Impact | Enhances product quality and lifecycle management | Improves operational efficiency and safety |

Which is better?

The digital thread enables seamless integration and real-time data flow across the entire manufacturing lifecycle, enhancing traceability and improving decision-making from design to production. SCADA systems provide crucial real-time monitoring and control of manufacturing processes but are primarily focused on operational data within individual plants. For comprehensive end-to-end process optimization and increased product quality, the digital thread offers a more strategic advantage compared to SCADA.

Connection

Digital thread integrates data across the entire manufacturing lifecycle, enabling real-time visibility and traceability of products and processes. SCADA systems collect and monitor operational data from manufacturing equipment, feeding critical information into the digital thread for analysis and decision-making. This connection enhances process optimization, predictive maintenance, and quality control throughout the production chain.

Key Terms

Real-time monitoring

SCADA systems provide real-time monitoring and control of industrial processes through centralized data acquisition and automated responses, ideal for operational stability and immediate fault detection. The Digital Thread integrates real-time data with a comprehensive lifecycle view of products, enabling predictive maintenance, enhanced decision-making, and continuous process improvement across interconnected systems. Explore the advantages of each technology to optimize real-time monitoring and operational efficiency.

Data integration

SCADA systems excel at real-time data acquisition and monitoring of industrial processes, enabling immediate control and alerting through sensor and actuator integration. The Digital Thread extends beyond SCADA by providing a continuous, integrated data flow throughout the product lifecycle, connecting design, manufacturing, and operational data for enhanced traceability and decision-making. Explore how these two technologies complement each other to optimize industrial data integration and improve operational efficiency.

Lifecycle traceability

SCADA systems excel in real-time monitoring and control of industrial processes but offer limited lifecycle traceability beyond operational data. The digital thread integrates data across the entire product lifecycle from design through manufacturing to service, providing comprehensive traceability and enabling improved decision-making. Explore how digital thread solutions can transform lifecycle management beyond SCADA capabilities.

Source and External Links

What is SCADA (Supervisory Control and Data Acquisition)? - SCADA systems are used to control and monitor industrial processes over large areas by collecting data via RTUs and PLCs, transmitting it to a central system for processing, and enabling operators to supervise and control processes in real time with alarms for deviations.

What is SCADA? Supervisory Control and Data Acquisition - SCADA integrates software and hardware to control and monitor industrial processes, allowing organizations to gather and analyze real-time data from various devices, make informed decisions, and maintain operational efficiency via human-machine interfaces (HMI).

What is SCADA? Supervisory Control and Data Acquisition - PTC - SCADA systems supervise industrial processes by collecting data from RTUs and PLCs, visualizing it through HMIs for operators to manage alarms, analyze trends, and support long-term strategic decision-making based on historical data.

dowidth.com

dowidth.com