Process mining harnesses data from manufacturing systems to uncover inefficiencies and bottlenecks in production workflows, enhancing transparency and operational performance. Supply chain optimization focuses on streamlining logistics, inventory management, and supplier coordination to reduce costs and improve delivery speed. Explore how integrating process mining with supply chain optimization can drive smarter manufacturing decisions and maximize efficiency.

Why it is important

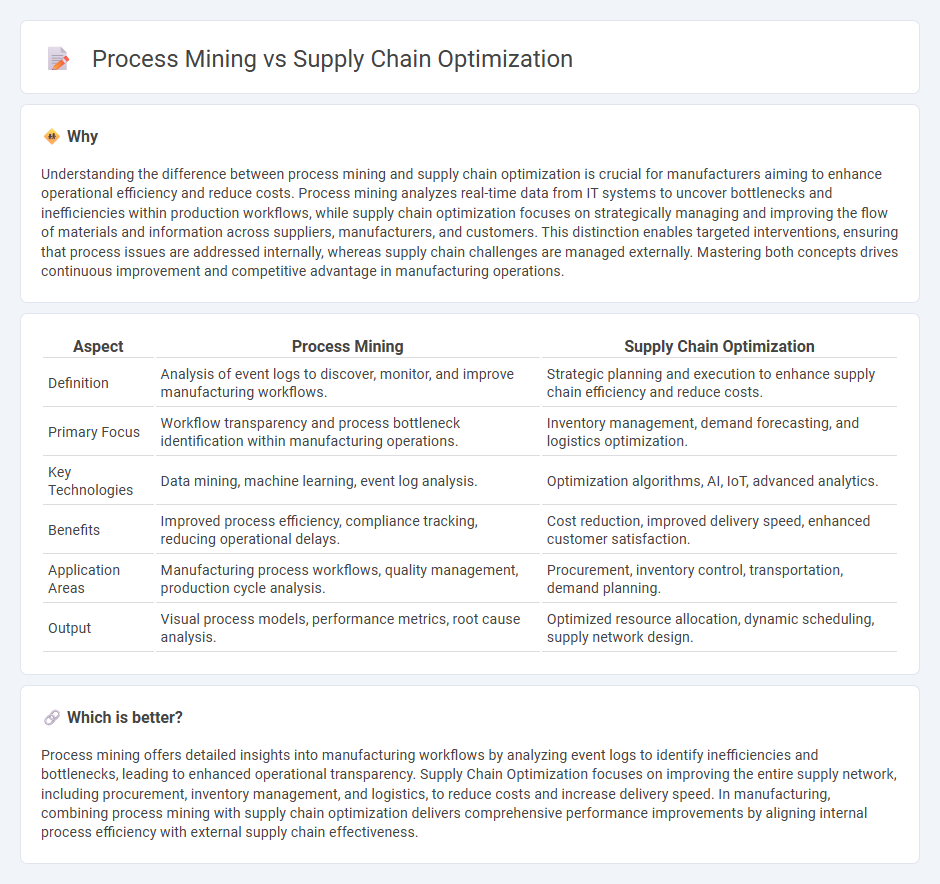

Understanding the difference between process mining and supply chain optimization is crucial for manufacturers aiming to enhance operational efficiency and reduce costs. Process mining analyzes real-time data from IT systems to uncover bottlenecks and inefficiencies within production workflows, while supply chain optimization focuses on strategically managing and improving the flow of materials and information across suppliers, manufacturers, and customers. This distinction enables targeted interventions, ensuring that process issues are addressed internally, whereas supply chain challenges are managed externally. Mastering both concepts drives continuous improvement and competitive advantage in manufacturing operations.

Comparison Table

| Aspect | Process Mining | Supply Chain Optimization |

|---|---|---|

| Definition | Analysis of event logs to discover, monitor, and improve manufacturing workflows. | Strategic planning and execution to enhance supply chain efficiency and reduce costs. |

| Primary Focus | Workflow transparency and process bottleneck identification within manufacturing operations. | Inventory management, demand forecasting, and logistics optimization. |

| Key Technologies | Data mining, machine learning, event log analysis. | Optimization algorithms, AI, IoT, advanced analytics. |

| Benefits | Improved process efficiency, compliance tracking, reducing operational delays. | Cost reduction, improved delivery speed, enhanced customer satisfaction. |

| Application Areas | Manufacturing process workflows, quality management, production cycle analysis. | Procurement, inventory control, transportation, demand planning. |

| Output | Visual process models, performance metrics, root cause analysis. | Optimized resource allocation, dynamic scheduling, supply network design. |

Which is better?

Process mining offers detailed insights into manufacturing workflows by analyzing event logs to identify inefficiencies and bottlenecks, leading to enhanced operational transparency. Supply Chain Optimization focuses on improving the entire supply network, including procurement, inventory management, and logistics, to reduce costs and increase delivery speed. In manufacturing, combining process mining with supply chain optimization delivers comprehensive performance improvements by aligning internal process efficiency with external supply chain effectiveness.

Connection

Process mining enables manufacturing companies to analyze real-time data from production workflows, identifying bottlenecks and inefficiencies. Supply chain optimization leverages these insights to enhance inventory management, reduce lead times, and improve supplier coordination. Integrating process mining with supply chain strategies drives operational excellence and cost reduction in manufacturing.

Key Terms

**Supply Chain Optimization:**

Supply Chain Optimization involves strategically managing and improving the flow of goods, information, and finances to enhance efficiency, reduce costs, and meet customer demands effectively. Techniques include demand forecasting, inventory management, logistics planning, and supplier collaboration, all aimed at minimizing disruptions and maximizing value. Explore more to uncover advanced strategies and tools driving superior supply chain performance.

Inventory Management

Supply chain optimization in inventory management leverages advanced analytics and demand forecasting to minimize stockouts and reduce holding costs, ensuring optimal stock levels across distribution centers. Process mining enhances this by providing real-time visibility into inventory-related processes, identifying bottlenecks and inefficiencies through data-driven insights from ERP and warehouse management systems. Explore how integrating these technologies can transform inventory management efficiency and responsiveness.

Demand Forecasting

Supply chain optimization leverages advanced algorithms and historical sales data to enhance demand forecasting accuracy, reducing inventory costs and improving customer satisfaction. Process mining uncovers hidden inefficiencies in supply chain workflows by analyzing event logs, providing insights that refine demand planning processes. Discover how integrating process mining with supply chain optimization can transform your demand forecasting strategy.

Source and External Links

What is Supply Chain Optimization? - Tibco - Supply chain optimization is the process of adjusting a supply chain's operations to maximize efficiency through systematic design, planning, and execution phases that consider everything from demand forecasting to transportation management and real-time decision support.

What Is Supply Chain Optimization? - IBM - This approach leverages advanced technologies like blockchain, AI, and IoT to enhance supply network efficiency, improve customer responsiveness, and balance supply with demand across network design, strategic planning, and execution-focused systems.

The Ultimate Guide to Supply Chain Optimization - Order.co - Supply chain optimization involves tactics such as assessing current practices, improving planning with scenario modeling, automating processes, expanding analytics with AI, and continuously negotiating with suppliers to drive cost efficiency and quality improvements.

dowidth.com

dowidth.com