Mass customization combines the efficiency of mass production with personalized product features, enabling manufacturers to deliver tailored solutions at scale. Engineer-to-Order (ETO) focuses on designing and producing unique, highly specialized products based on specific client requirements, often involving complex engineering processes and longer lead times. Explore how these manufacturing strategies impact production flexibility and customer satisfaction for a deeper understanding.

Why it is important

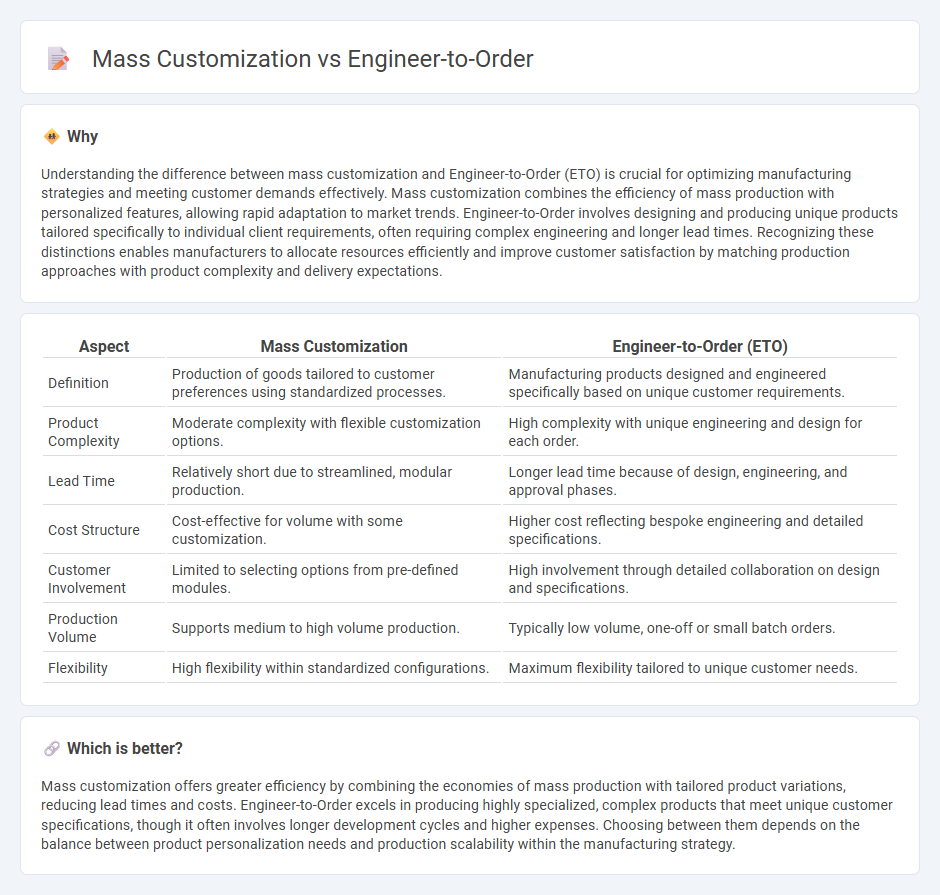

Understanding the difference between mass customization and Engineer-to-Order (ETO) is crucial for optimizing manufacturing strategies and meeting customer demands effectively. Mass customization combines the efficiency of mass production with personalized features, allowing rapid adaptation to market trends. Engineer-to-Order involves designing and producing unique products tailored specifically to individual client requirements, often requiring complex engineering and longer lead times. Recognizing these distinctions enables manufacturers to allocate resources efficiently and improve customer satisfaction by matching production approaches with product complexity and delivery expectations.

Comparison Table

| Aspect | Mass Customization | Engineer-to-Order (ETO) |

|---|---|---|

| Definition | Production of goods tailored to customer preferences using standardized processes. | Manufacturing products designed and engineered specifically based on unique customer requirements. |

| Product Complexity | Moderate complexity with flexible customization options. | High complexity with unique engineering and design for each order. |

| Lead Time | Relatively short due to streamlined, modular production. | Longer lead time because of design, engineering, and approval phases. |

| Cost Structure | Cost-effective for volume with some customization. | Higher cost reflecting bespoke engineering and detailed specifications. |

| Customer Involvement | Limited to selecting options from pre-defined modules. | High involvement through detailed collaboration on design and specifications. |

| Production Volume | Supports medium to high volume production. | Typically low volume, one-off or small batch orders. |

| Flexibility | High flexibility within standardized configurations. | Maximum flexibility tailored to unique customer needs. |

Which is better?

Mass customization offers greater efficiency by combining the economies of mass production with tailored product variations, reducing lead times and costs. Engineer-to-Order excels in producing highly specialized, complex products that meet unique customer specifications, though it often involves longer development cycles and higher expenses. Choosing between them depends on the balance between product personalization needs and production scalability within the manufacturing strategy.

Connection

Mass customization and Engineer-to-Order (ETO) are interconnected manufacturing strategies that emphasize tailored production to meet specific customer requirements. Mass customization enables flexible manufacturing processes to efficiently produce individualized products at scale, while Engineer-to-Order involves designing and manufacturing products based on unique specifications after receiving customer orders, requiring extensive engineering input and coordination. Both approaches leverage advanced digital technologies, such as CAD, CAD/CAM systems, and modular design, to streamline production and reduce lead times.

Key Terms

Lead Time

Engineer-to-Order (ETO) processes prioritize unique, customized products often resulting in significantly longer lead times due to design and engineering requirements. Mass customization leverages standardized components and flexible manufacturing to achieve shorter lead times while offering personalized options. Explore detailed comparisons to optimize your production strategy and reduce time-to-market.

Product Configurability

Engineer-to-Order (ETO) emphasizes unique, highly customized products designed and manufactured per individual customer specifications, offering maximal product configurability through extensive engineering input and flexible manufacturing processes. In contrast, mass customization integrates customization options within a standardized production framework, enabling moderate configurability by allowing customers to select from predefined modules or features without altering core design elements. Explore how these distinct approaches optimize product configurability to meet diverse market demands.

Design Complexity

Engineer-to-Order (ETO) projects involve high design complexity as each product is tailored to specific customer requirements, demanding unique engineering and detailed customization. In contrast, mass customization leverages modular design and flexible manufacturing systems to offer personalized products while maintaining lower design complexity and faster production cycles. Explore how these approaches impact product development and operational efficiency for your business needs.

Source and External Links

Engineer to order - Wikipedia - Engineer to order (ETO) is a manufacturing approach where products are designed and engineered after a customer order is received, involving substantial design work and requiring a flexible, demand-driven process for highly customized solutions.

What Is Engineer To Order - Total ETO - ETO is a design and build process focused on flexibility and customization, involving close collaboration between customer and engineering teams to create unique products, and often needing specialized software to manage complexity.

Engineer-to-Order: A Practical Guide - Acumatica - The ETO process includes customer specification review, preliminary then detailed engineering, production planning, manufacturing, testing, and delivery, offering customized products but also presenting challenges like longer lead times and engineering bottlenecks.

dowidth.com

dowidth.com