Digital twinning creates real-time, virtual replicas of physical manufacturing processes to optimize performance and predict maintenance needs, surpassing traditional CAD/CAM systems that focus mainly on design and tooling. While CAD/CAM excels in precise product modeling and automated fabrication, digital twinning integrates IoT data and analytics for dynamic simulation and operational insight. Explore the transformative benefits of digital twinning to enhance manufacturing efficiency and innovation.

Why it is important

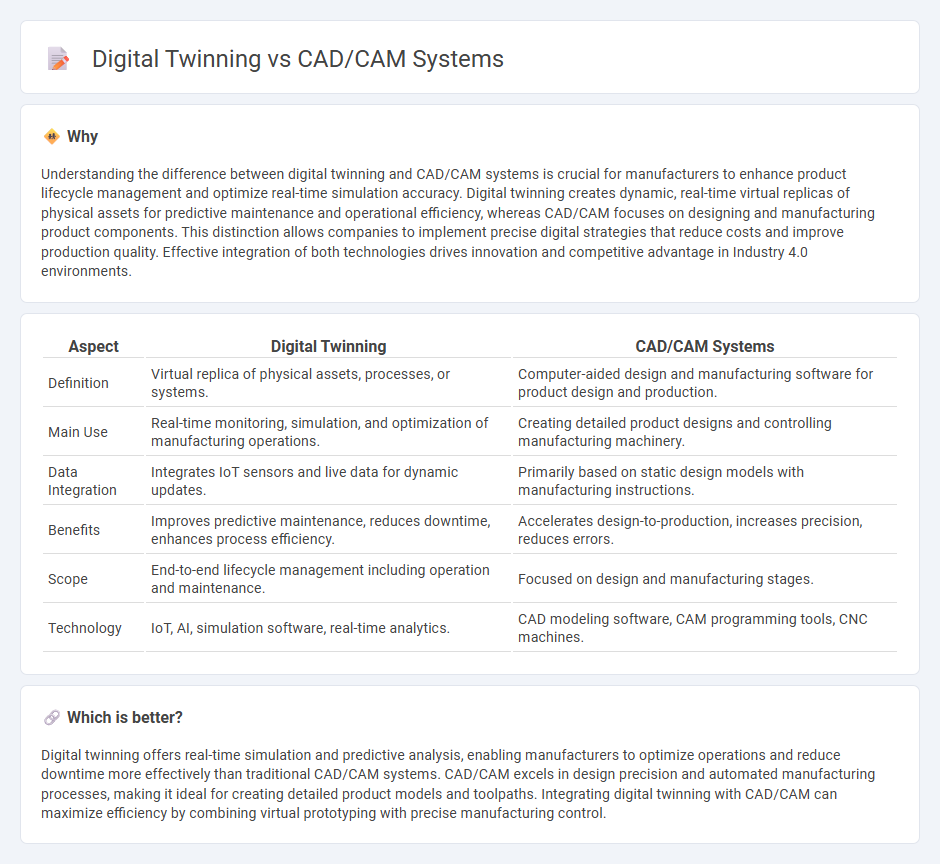

Understanding the difference between digital twinning and CAD/CAM systems is crucial for manufacturers to enhance product lifecycle management and optimize real-time simulation accuracy. Digital twinning creates dynamic, real-time virtual replicas of physical assets for predictive maintenance and operational efficiency, whereas CAD/CAM focuses on designing and manufacturing product components. This distinction allows companies to implement precise digital strategies that reduce costs and improve production quality. Effective integration of both technologies drives innovation and competitive advantage in Industry 4.0 environments.

Comparison Table

| Aspect | Digital Twinning | CAD/CAM Systems |

|---|---|---|

| Definition | Virtual replica of physical assets, processes, or systems. | Computer-aided design and manufacturing software for product design and production. |

| Main Use | Real-time monitoring, simulation, and optimization of manufacturing operations. | Creating detailed product designs and controlling manufacturing machinery. |

| Data Integration | Integrates IoT sensors and live data for dynamic updates. | Primarily based on static design models with manufacturing instructions. |

| Benefits | Improves predictive maintenance, reduces downtime, enhances process efficiency. | Accelerates design-to-production, increases precision, reduces errors. |

| Scope | End-to-end lifecycle management including operation and maintenance. | Focused on design and manufacturing stages. |

| Technology | IoT, AI, simulation software, real-time analytics. | CAD modeling software, CAM programming tools, CNC machines. |

Which is better?

Digital twinning offers real-time simulation and predictive analysis, enabling manufacturers to optimize operations and reduce downtime more effectively than traditional CAD/CAM systems. CAD/CAM excels in design precision and automated manufacturing processes, making it ideal for creating detailed product models and toolpaths. Integrating digital twinning with CAD/CAM can maximize efficiency by combining virtual prototyping with precise manufacturing control.

Connection

Digital twinning leverages CAD/CAM systems by using their detailed design models to create virtual replicas of physical manufacturing processes. These digital replicas allow for real-time monitoring, simulation, and optimization of production lines, reducing downtime and increasing efficiency. CAD/CAM data ensures the digital twin accurately mirrors the physical machinery and product specifications, enabling precise control and predictive maintenance.

Key Terms

3D Modeling

CAD/CAM systems excel in designing and manufacturing by creating precise 3D models used directly in production processes, enabling detailed geometry and material specifications. Digital twinning extends beyond static 3D modeling by simulating real-time performance and interaction of virtual models with their physical counterparts, allowing continuous optimization and predictive maintenance. Explore how these technologies transform 3D modeling and manufacturing efficiency by diving deeper into their unique capabilities and applications.

Simulation

CAD/CAM systems enable precise design and manufacturing processes through computer-aided modeling and automated toolpath generation, streamlining production workflows and minimizing errors. Digital twinning advances simulation by creating real-time virtual replicas of physical assets, allowing continuous monitoring, predictive maintenance, and performance optimization based on live data. Explore how integrating digital twinning with CAD/CAM can revolutionize simulation accuracy and operational efficiency.

Data Integration

CAD/CAM systems streamline design and manufacturing by integrating precise 3D models and toolpath data within production workflows, enhancing machining accuracy and efficiency. Digital twinning extends this integration by creating real-time, dynamic virtual replicas of physical assets, enabling continuous data synchronization from sensors and IoT devices for predictive maintenance and process optimization. Explore how advanced data integration in these technologies transforms industrial innovation and operational resilience.

Source and External Links

What is a CAD/CAM system? - SprutCAM X - CAD/CAM systems integrate computer-aided design and manufacturing software, enabling seamless transition from design to production, improving workflow efficiency, reducing errors, and optimizing manufacturing processes, widely used across industries requiring high precision like aerospace and automotive.

What is Integrated CAD CAM software? | HCL CAMWorks - Integrated CAD/CAM software combines design and manufacturing functions into a single platform to eliminate translation errors, reduce production costs and delays, and improve collaboration between design and manufacturing teams.

CAD/CAM Software for Design & Manufacturing - Autodesk - CAD/CAM software both designs products and programs manufacturing processes like CNC machining, streamlining product development from concept to production with enhanced accuracy and productivity through unified workflows.

dowidth.com

dowidth.com