Automated guided vehicles (AGVs) offer flexible, programmable material transport within manufacturing facilities, enhancing operational efficiency and reducing labor costs. Overhead cranes provide heavy lifting capabilities with precise load control, essential for handling bulky or high-weight materials in production environments. Explore deeper insights to determine the optimal material handling solution for your manufacturing needs.

Why it is important

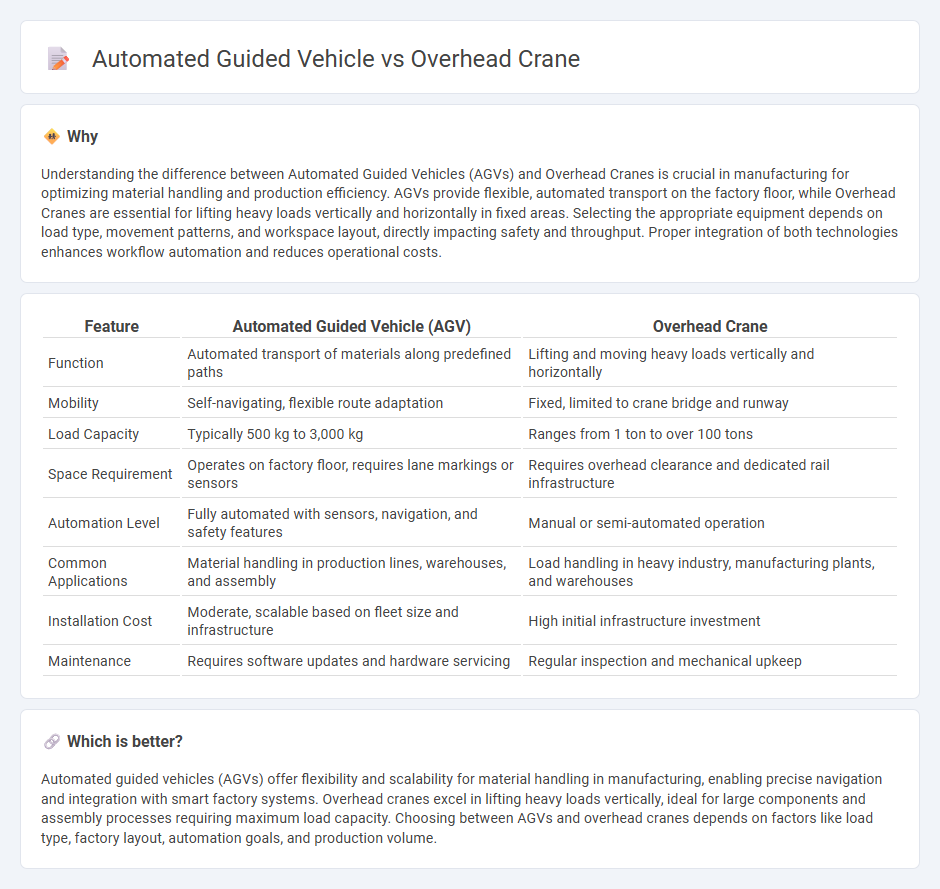

Understanding the difference between Automated Guided Vehicles (AGVs) and Overhead Cranes is crucial in manufacturing for optimizing material handling and production efficiency. AGVs provide flexible, automated transport on the factory floor, while Overhead Cranes are essential for lifting heavy loads vertically and horizontally in fixed areas. Selecting the appropriate equipment depends on load type, movement patterns, and workspace layout, directly impacting safety and throughput. Proper integration of both technologies enhances workflow automation and reduces operational costs.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Overhead Crane |

|---|---|---|

| Function | Automated transport of materials along predefined paths | Lifting and moving heavy loads vertically and horizontally |

| Mobility | Self-navigating, flexible route adaptation | Fixed, limited to crane bridge and runway |

| Load Capacity | Typically 500 kg to 3,000 kg | Ranges from 1 ton to over 100 tons |

| Space Requirement | Operates on factory floor, requires lane markings or sensors | Requires overhead clearance and dedicated rail infrastructure |

| Automation Level | Fully automated with sensors, navigation, and safety features | Manual or semi-automated operation |

| Common Applications | Material handling in production lines, warehouses, and assembly | Load handling in heavy industry, manufacturing plants, and warehouses |

| Installation Cost | Moderate, scalable based on fleet size and infrastructure | High initial infrastructure investment |

| Maintenance | Requires software updates and hardware servicing | Regular inspection and mechanical upkeep |

Which is better?

Automated guided vehicles (AGVs) offer flexibility and scalability for material handling in manufacturing, enabling precise navigation and integration with smart factory systems. Overhead cranes excel in lifting heavy loads vertically, ideal for large components and assembly processes requiring maximum load capacity. Choosing between AGVs and overhead cranes depends on factors like load type, factory layout, automation goals, and production volume.

Connection

Automated guided vehicles (AGVs) and overhead cranes integrate seamlessly in manufacturing environments to enhance material handling efficiency and reduce manual labor. AGVs transport raw materials or finished products across the factory floor, while overhead cranes handle heavy lifting and precise placement, enabling coordinated movement of goods within complex production workflows. This synergy optimizes spatial use, minimizes downtime, and supports just-in-time manufacturing processes through synchronized automation systems.

Key Terms

Material Handling

Overhead cranes provide efficient vertical and horizontal material handling in manufacturing and warehouse environments, capable of lifting heavy loads with precision and minimal floor space usage. Automated guided vehicles (AGVs) enhance flexibility by transporting materials autonomously along predetermined paths, improving workflow automation and reducing labor costs. Explore how integrating overhead cranes and AGVs can optimize your material handling operations for increased productivity and safety.

Automation

Overhead cranes excel in lifting heavy loads with precise vertical and horizontal movement in fixed industrial spaces, while automated guided vehicles (AGVs) offer flexible, autonomous transport across dynamic factory floors. AGVs leverage advanced sensors and AI for real-time navigation and adaptability, enhancing automation efficiency compared to the mechanically guided operation of overhead cranes. Discover how integrating these technologies can optimize your automated material handling processes.

Load Capacity

Overhead cranes typically offer higher load capacities, ranging from a few tons to over 100 tons, making them ideal for heavy industrial lifting. Automated guided vehicles (AGVs) generally handle lower loads, often under 5 tons, suited for flexible and repetitive material transport in warehouses or production floors. Explore the detailed load specifications and application contexts to determine the best solution for your operational needs.

Source and External Links

Overhead crane - Wikipedia - An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments, consisting of parallel rails with a traveling bridge and hoist for moving heavy loads horizontally across a facility.

What is an Overhead Crane? - Amquip - An overhead crane is a machine that moves loads horizontally across the ceiling of a facility, offering significant lifting power and efficiency for material transport in industrial settings.

Overhead Bridge Cranes for Sale - Crane Depot - Overhead bridge cranes are utilized for heavy-duty material handling, operating at high speeds and lifting large loads without adding floor obstructions, and are available in single or double girder configurations.

dowidth.com

dowidth.com