Factory as a Service (FaaS) offers scalable, on-demand manufacturing solutions by leveraging cloud-based platforms to optimize production workflows, reduce capital expenditure, and enhance operational flexibility. Industrial Internet of Things (IIoT) integrates smart sensors, machines, and data analytics to enable real-time monitoring, predictive maintenance, and intelligent automation in manufacturing environments. Discover how FaaS and IIoT are transforming industrial processes with cutting-edge technology and data-driven efficiency.

Why it is important

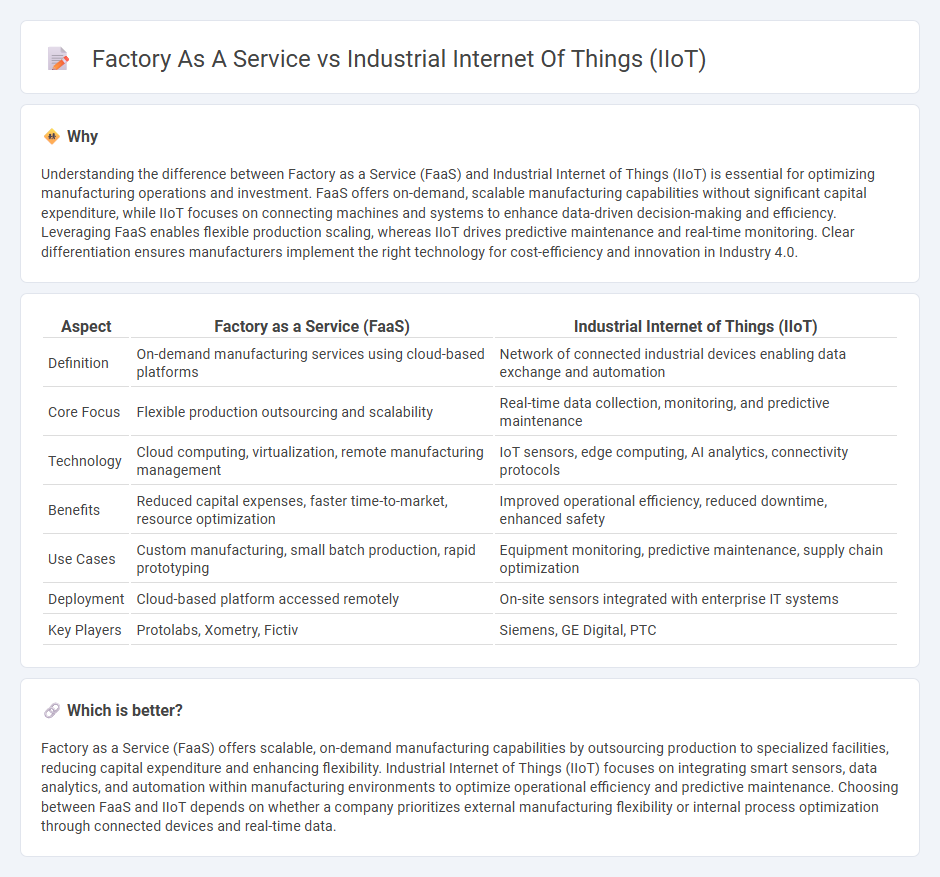

Understanding the difference between Factory as a Service (FaaS) and Industrial Internet of Things (IIoT) is essential for optimizing manufacturing operations and investment. FaaS offers on-demand, scalable manufacturing capabilities without significant capital expenditure, while IIoT focuses on connecting machines and systems to enhance data-driven decision-making and efficiency. Leveraging FaaS enables flexible production scaling, whereas IIoT drives predictive maintenance and real-time monitoring. Clear differentiation ensures manufacturers implement the right technology for cost-efficiency and innovation in Industry 4.0.

Comparison Table

| Aspect | Factory as a Service (FaaS) | Industrial Internet of Things (IIoT) |

|---|---|---|

| Definition | On-demand manufacturing services using cloud-based platforms | Network of connected industrial devices enabling data exchange and automation |

| Core Focus | Flexible production outsourcing and scalability | Real-time data collection, monitoring, and predictive maintenance |

| Technology | Cloud computing, virtualization, remote manufacturing management | IoT sensors, edge computing, AI analytics, connectivity protocols |

| Benefits | Reduced capital expenses, faster time-to-market, resource optimization | Improved operational efficiency, reduced downtime, enhanced safety |

| Use Cases | Custom manufacturing, small batch production, rapid prototyping | Equipment monitoring, predictive maintenance, supply chain optimization |

| Deployment | Cloud-based platform accessed remotely | On-site sensors integrated with enterprise IT systems |

| Key Players | Protolabs, Xometry, Fictiv | Siemens, GE Digital, PTC |

Which is better?

Factory as a Service (FaaS) offers scalable, on-demand manufacturing capabilities by outsourcing production to specialized facilities, reducing capital expenditure and enhancing flexibility. Industrial Internet of Things (IIoT) focuses on integrating smart sensors, data analytics, and automation within manufacturing environments to optimize operational efficiency and predictive maintenance. Choosing between FaaS and IIoT depends on whether a company prioritizes external manufacturing flexibility or internal process optimization through connected devices and real-time data.

Connection

Factory as a Service (FaaS) leverages Industrial Internet of Things (IIoT) technology to enable real-time monitoring, automation, and flexible manufacturing processes remotely through cloud platforms. IIoT integrates sensors, devices, and data analytics to optimize production efficiency, asset management, and predictive maintenance within FaaS environments. This interconnected system enhances scalability, reduces downtime, and supports dynamic resource allocation in modern smart factories.

Key Terms

Connectivity

Industrial Internet of Things (IIoT) leverages advanced sensors, real-time data analytics, and machine-to-machine communication to enhance connectivity within manufacturing environments, enabling predictive maintenance and optimized operations. Factory as a Service (FaaS) integrates cloud-based platforms with modular production units, offering scalable and flexible connectivity solutions that support remote monitoring and dynamic resource allocation. Explore further to understand how connectivity innovations drive efficiency and transformation in modern industrial ecosystems.

Data Analytics

Industrial Internet of Things (IIoT) leverages interconnected sensors and devices to collect real-time data enabling predictive maintenance, process optimization, and enhanced operational efficiency in manufacturing environments. Factory as a Service (FaaS) integrates flexible, on-demand factory resources with advanced data analytics platforms that provide actionable insights and scalable production capabilities without heavy capital investments. Explore how IIoT and FaaS transform industrial data analytics to maximize productivity and cost-efficiency.

Servitization

Industrial Internet of Things (IIoT) enhances manufacturing efficiency by connecting devices and enabling real-time data analytics, driving predictive maintenance and operational optimization. Factory as a Service (FaaS) leverages servitization, offering scalable, flexible manufacturing solutions through on-demand access to production capabilities without heavy capital investment. Explore how integrating IIoT with servitization in FaaS models transforms industrial operations and accelerates digital transformation.

Source and External Links

Industrial IoT | Digital Transformation - AWS - IIoT integrates machines, cloud computing, and analytics to enhance industrial performance, productivity, and process optimization across industries like manufacturing, energy, and utilities.

What is IIoT (Industrial Internet of Things)? | Definition from TechTarget - IIoT connects smart sensors and devices to monitor, collect, and analyze data, enabling predictive maintenance, quality control, and improved efficiency in industrial settings.

The Industrial Internet of Things: A Primer - Splunk - IIoT platforms combine hardware and software to centralize control of industrial processes, offering real-time analytics, automation, and operational visibility for cost savings and increased productivity.

dowidth.com

dowidth.com