Biofabrication leverages advanced 3D bioprinting technologies to create living tissues and organs layer by layer, offering precision and customization unattainable by traditional methods. Injection molding utilizes high-pressure injection of molten materials into molds for mass production, emphasizing speed and cost-efficiency in manufacturing plastic components. Explore the distinctive advantages and applications of biofabrication and injection molding to understand their transformative roles in modern manufacturing.

Why it is important

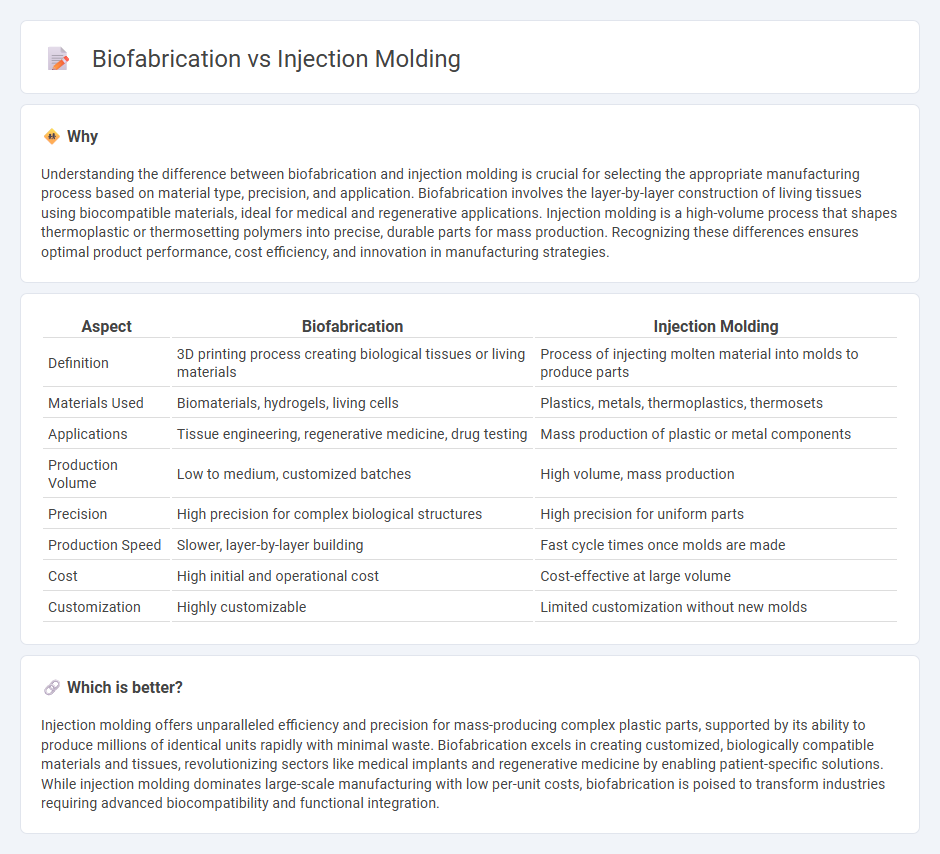

Understanding the difference between biofabrication and injection molding is crucial for selecting the appropriate manufacturing process based on material type, precision, and application. Biofabrication involves the layer-by-layer construction of living tissues using biocompatible materials, ideal for medical and regenerative applications. Injection molding is a high-volume process that shapes thermoplastic or thermosetting polymers into precise, durable parts for mass production. Recognizing these differences ensures optimal product performance, cost efficiency, and innovation in manufacturing strategies.

Comparison Table

| Aspect | Biofabrication | Injection Molding |

|---|---|---|

| Definition | 3D printing process creating biological tissues or living materials | Process of injecting molten material into molds to produce parts |

| Materials Used | Biomaterials, hydrogels, living cells | Plastics, metals, thermoplastics, thermosets |

| Applications | Tissue engineering, regenerative medicine, drug testing | Mass production of plastic or metal components |

| Production Volume | Low to medium, customized batches | High volume, mass production |

| Precision | High precision for complex biological structures | High precision for uniform parts |

| Production Speed | Slower, layer-by-layer building | Fast cycle times once molds are made |

| Cost | High initial and operational cost | Cost-effective at large volume |

| Customization | Highly customizable | Limited customization without new molds |

Which is better?

Injection molding offers unparalleled efficiency and precision for mass-producing complex plastic parts, supported by its ability to produce millions of identical units rapidly with minimal waste. Biofabrication excels in creating customized, biologically compatible materials and tissues, revolutionizing sectors like medical implants and regenerative medicine by enabling patient-specific solutions. While injection molding dominates large-scale manufacturing with low per-unit costs, biofabrication is poised to transform industries requiring advanced biocompatibility and functional integration.

Connection

Biofabrication leverages advanced materials and 3D printing techniques that complement the precision and scalability of injection molding in manufacturing. Injection molding enables mass production of biofabricated components by creating detailed molds tailored for biocompatible polymers and hydrogels. This synergy accelerates the development of complex biomedical devices and tissue engineering scaffolds with enhanced structural integrity and functional properties.

Key Terms

Mold design

Injection molding relies on precision mold design to create complex, reproducible plastic components by injecting molten material into metal molds, enabling high-volume production with tight tolerances. Biofabrication mold design, however, focuses on creating biocompatible structures using soft lithography or scaffold molds that support cell growth and tissue engineering, prioritizing material biocompatibility and porosity. Explore the latest advances in mold design techniques to optimize your manufacturing or biofabrication processes.

Biomaterial scaffolds

Injection molding offers precise control over scaffold geometry and mechanical properties, making it ideal for producing biomaterial scaffolds with consistent shapes and sizes. Biofabrication techniques, such as 3D bioprinting, enable the creation of highly complex, cell-laden scaffolds that better mimic native tissue architecture and promote cellular function. Explore the latest advancements in biomaterial scaffold fabrication to understand which method best suits your biomedical application.

Additive manufacturing

Injection molding offers high-volume production with precise dimensional control, ideal for consistent plastic parts, while biofabrication leverages additive manufacturing techniques to create complex, living tissue structures with cellular precision. Additive manufacturing in biofabrication enables layer-by-layer deposition of biomaterials and cells, supporting customization and rapid prototyping in regenerative medicine. Explore detailed comparisons and innovations to understand how these technologies are transforming manufacturing and healthcare sectors.

Source and External Links

Injection moulding - Injection molding is a manufacturing process where molten material, usually thermoplastics, is injected into a precision-machined metal mold to form parts, widely used from small components to automotive body panels.

The outline of injection molding - Injection molding involves melting plastic material, injecting it into a mold cavity, cooling to solidify, and then ejecting the finished product, making it ideal for mass production of complex shapes.

A Beginner's Guide to Injection Molding - The process starts with CNC-milled steel or aluminum tooling, molten plastic resin is injected into molds, then cooled and ejected; common types include thermoplastic molding, liquid silicone rubber molding, overmolding, and insert molding.

dowidth.com

dowidth.com