Industrial metaverse integrates virtual reality and digital twins to revolutionize manufacturing processes by enhancing real-time collaboration and simulation. Supply chain digitalization focuses on optimizing logistics and inventory management through IoT, AI, and blockchain technologies to improve transparency and efficiency. Explore the distinct advantages and potential impacts of the industrial metaverse and supply chain digitalization in transforming modern manufacturing.

Why it is important

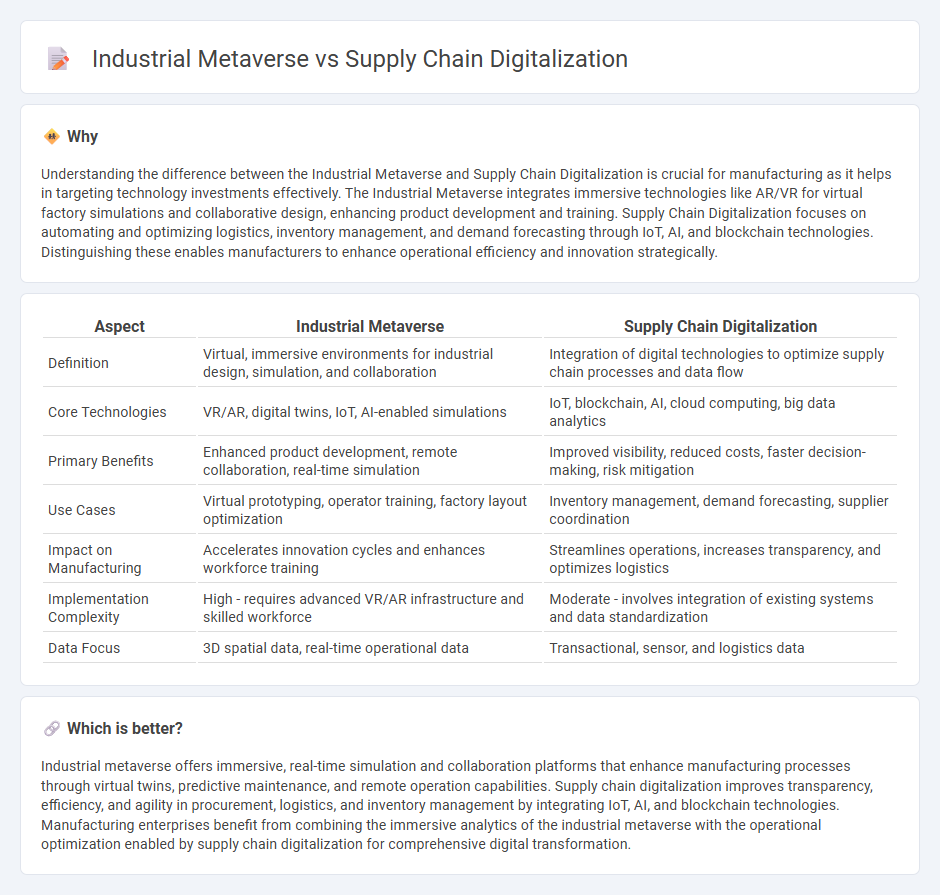

Understanding the difference between the Industrial Metaverse and Supply Chain Digitalization is crucial for manufacturing as it helps in targeting technology investments effectively. The Industrial Metaverse integrates immersive technologies like AR/VR for virtual factory simulations and collaborative design, enhancing product development and training. Supply Chain Digitalization focuses on automating and optimizing logistics, inventory management, and demand forecasting through IoT, AI, and blockchain technologies. Distinguishing these enables manufacturers to enhance operational efficiency and innovation strategically.

Comparison Table

| Aspect | Industrial Metaverse | Supply Chain Digitalization |

|---|---|---|

| Definition | Virtual, immersive environments for industrial design, simulation, and collaboration | Integration of digital technologies to optimize supply chain processes and data flow |

| Core Technologies | VR/AR, digital twins, IoT, AI-enabled simulations | IoT, blockchain, AI, cloud computing, big data analytics |

| Primary Benefits | Enhanced product development, remote collaboration, real-time simulation | Improved visibility, reduced costs, faster decision-making, risk mitigation |

| Use Cases | Virtual prototyping, operator training, factory layout optimization | Inventory management, demand forecasting, supplier coordination |

| Impact on Manufacturing | Accelerates innovation cycles and enhances workforce training | Streamlines operations, increases transparency, and optimizes logistics |

| Implementation Complexity | High - requires advanced VR/AR infrastructure and skilled workforce | Moderate - involves integration of existing systems and data standardization |

| Data Focus | 3D spatial data, real-time operational data | Transactional, sensor, and logistics data |

Which is better?

Industrial metaverse offers immersive, real-time simulation and collaboration platforms that enhance manufacturing processes through virtual twins, predictive maintenance, and remote operation capabilities. Supply chain digitalization improves transparency, efficiency, and agility in procurement, logistics, and inventory management by integrating IoT, AI, and blockchain technologies. Manufacturing enterprises benefit from combining the immersive analytics of the industrial metaverse with the operational optimization enabled by supply chain digitalization for comprehensive digital transformation.

Connection

The industrial metaverse integrates digital twins and real-time data analytics to enhance supply chain visibility, enabling predictive maintenance and optimized resource allocation. Supply chain digitalization leverages IoT sensors, blockchain technology, and AI-driven insights within virtual environments to improve transparency, traceability, and collaboration across manufacturing networks. This synergy accelerates decision-making, reduces operational costs, and drives agility in meeting dynamic market demands.

Key Terms

IoT Integration

Supply chain digitalization leverages IoT integration to enhance real-time visibility, asset tracking, and predictive maintenance, driving operational efficiency and cost reduction. The industrial metaverse extends IoT by creating immersive digital twins and virtual environments for advanced simulation, collaboration, and decision-making across supply chain networks. Explore how IoT-powered innovations transform supply chains through both digitalization and the emerging industrial metaverse for smarter operations.

Real-Time Data Visualization

Supply chain digitalization enhances operational efficiency by integrating real-time data visualization tools such as IoT sensors and AI-driven analytics to monitor inventory levels, shipment status, and demand fluctuations. The industrial metaverse offers immersive virtual environments where stakeholders can interact with dynamic digital twins for advanced scenario planning and predictive maintenance. Explore how combining these technologies revolutionizes supply chain management for greater responsiveness and strategic insight.

Digital Twins

Digital twins serve as a critical intersection between supply chain digitalization and the industrial metaverse, enabling real-time simulation and optimization of manufacturing processes and logistics. Advanced sensors, IoT, and AI integration in digital twins provide enhanced visibility and predictive analytics across the supply chain, driving efficiency and reducing downtime. Explore how digital twins revolutionize supply chain management within the industrial metaverse to elevate operational intelligence.

Source and External Links

What Is Supply Chain Digitization? Benefits, Challenges... - Supply chain digitization replaces manual processes with technology to create interconnected, data-driven, and automated workflows for improved visibility, efficiency, and error reduction.

What Is Supply Chain Digitization & Why Is It Important? - Digitizing the supply chain involves integrating digital tools for data management, process automation, and real-time analytics, enabling faster, more accurate, and flexible operations throughout the supply chain.

Navigating the Digital Supply Chain Revolution - Digital supply chains leverage IoT, AI, blockchain, and cloud computing to create agile, transparent, and responsive ecosystems, marking a shift from traditional manual processes towards end-to-end digital integration.

dowidth.com

dowidth.com