Zero defect manufacturing focuses on eliminating defects through strict process controls and employee accountability to achieve flawless production outputs. Total Quality Management (TQM) emphasizes continuous improvement involving all organizational levels to enhance product quality and customer satisfaction. Explore the fundamental differences and benefits of these methodologies to optimize your manufacturing processes.

Why it is important

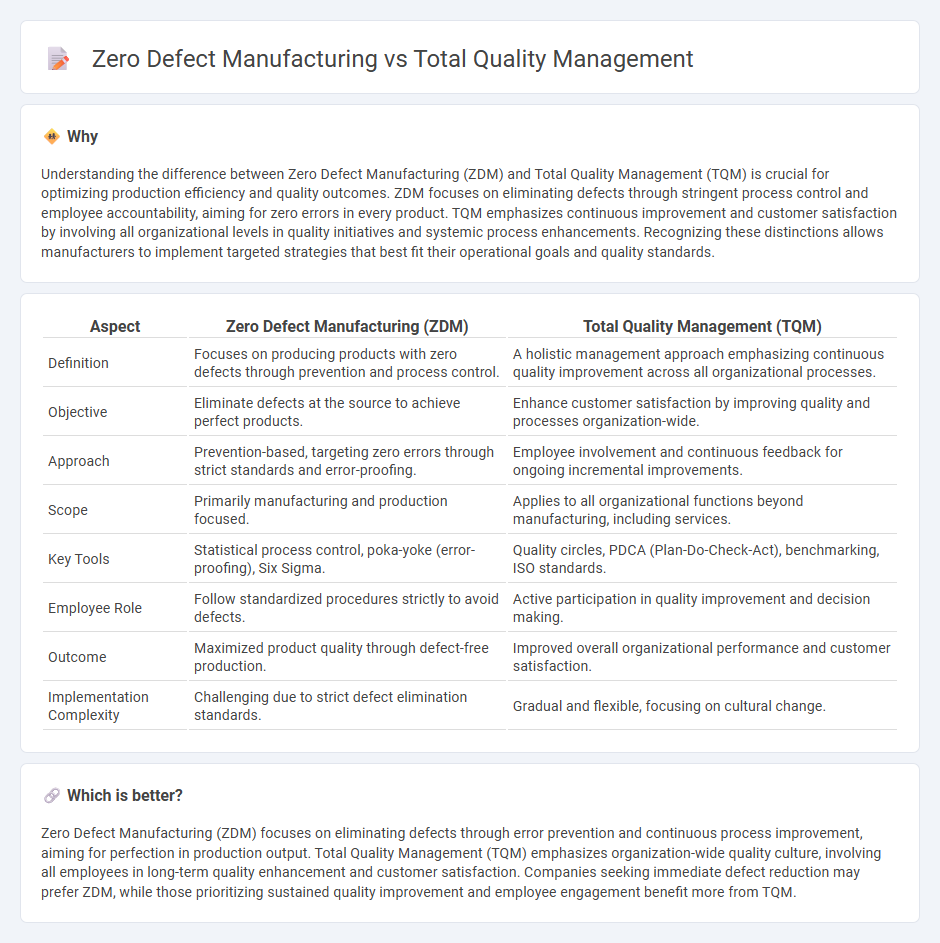

Understanding the difference between Zero Defect Manufacturing (ZDM) and Total Quality Management (TQM) is crucial for optimizing production efficiency and quality outcomes. ZDM focuses on eliminating defects through stringent process control and employee accountability, aiming for zero errors in every product. TQM emphasizes continuous improvement and customer satisfaction by involving all organizational levels in quality initiatives and systemic process enhancements. Recognizing these distinctions allows manufacturers to implement targeted strategies that best fit their operational goals and quality standards.

Comparison Table

| Aspect | Zero Defect Manufacturing (ZDM) | Total Quality Management (TQM) |

|---|---|---|

| Definition | Focuses on producing products with zero defects through prevention and process control. | A holistic management approach emphasizing continuous quality improvement across all organizational processes. |

| Objective | Eliminate defects at the source to achieve perfect products. | Enhance customer satisfaction by improving quality and processes organization-wide. |

| Approach | Prevention-based, targeting zero errors through strict standards and error-proofing. | Employee involvement and continuous feedback for ongoing incremental improvements. |

| Scope | Primarily manufacturing and production focused. | Applies to all organizational functions beyond manufacturing, including services. |

| Key Tools | Statistical process control, poka-yoke (error-proofing), Six Sigma. | Quality circles, PDCA (Plan-Do-Check-Act), benchmarking, ISO standards. |

| Employee Role | Follow standardized procedures strictly to avoid defects. | Active participation in quality improvement and decision making. |

| Outcome | Maximized product quality through defect-free production. | Improved overall organizational performance and customer satisfaction. |

| Implementation Complexity | Challenging due to strict defect elimination standards. | Gradual and flexible, focusing on cultural change. |

Which is better?

Zero Defect Manufacturing (ZDM) focuses on eliminating defects through error prevention and continuous process improvement, aiming for perfection in production output. Total Quality Management (TQM) emphasizes organization-wide quality culture, involving all employees in long-term quality enhancement and customer satisfaction. Companies seeking immediate defect reduction may prefer ZDM, while those prioritizing sustained quality improvement and employee engagement benefit more from TQM.

Connection

Zero Defect Manufacturing (ZDM) and Total Quality Management (TQM) are interconnected through their shared focus on minimizing defects and enhancing product quality in manufacturing processes. ZDM aims for perfect products with no defects by emphasizing process control and continuous improvement, while TQM provides a holistic framework involving employee involvement, quality culture, and systematic process management. Together, they drive operational excellence, reduce waste, and improve customer satisfaction in manufacturing industries.

Key Terms

**Total Quality Management:**

Total Quality Management (TQM) emphasizes continuous improvement in processes, involving every employee from top management to frontline workers to enhance product quality and customer satisfaction. It integrates systematic problem-solving and preventive measures, aiming for long-term organizational success rather than short-term defect elimination. Explore more on how TQM drives sustainable quality excellence and operational efficiency.

Continuous Improvement

Total Quality Management (TQM) emphasizes continuous improvement through systematic processes, employee involvement, and customer-focused strategies to enhance overall organizational quality. Zero Defect Manufacturing targets defect prevention by implementing strict quality controls and precise operational procedures to achieve a near-perfect production output. Explore in-depth comparisons to understand how these approaches drive excellence in manufacturing and quality management.

Customer Focus

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction by involving all employees in quality initiatives, ensuring products meet or exceed customer expectations. Zero Defect Manufacturing (ZDM) focuses on defect prevention through stringent quality controls and error-proofing processes, aiming for flawless products with no tolerances for mistakes. Discover how both strategies prioritize customer focus yet differ in execution for enhancing product quality and reliability.

Source and External Links

Total Quality Management (TQM): What Is It, Principles and ... - Total Quality Management is a management approach focused on delivering the highest quality products and services by involving all employees in continuous improvement to maximize customer satisfaction.

BUS 314: TOTAL QUALITY MANAGEMENT Topic 1 - TQM is a management philosophy emphasizing continuous improvement across an organization's operations with key principles including customer focus, employee involvement, and fact-based decision making.

Introduction and Implementation of Total Quality ... - TQM integrates all organizational functions with principles such as management commitment, employee empowerment, fact-based decision making, continuous improvement, and customer focus applied throughout the organization.

dowidth.com

dowidth.com