Cobotics integrates collaborative robots directly with human workers to enhance efficiency and safety in manufacturing environments, focusing on precision and adaptability. Industrial IoT leverages interconnected sensors and devices to collect real-time data, optimizing production processes through advanced analytics and predictive maintenance. Explore how combining cobotics and Industrial IoT can transform manufacturing productivity and innovation.

Why it is important

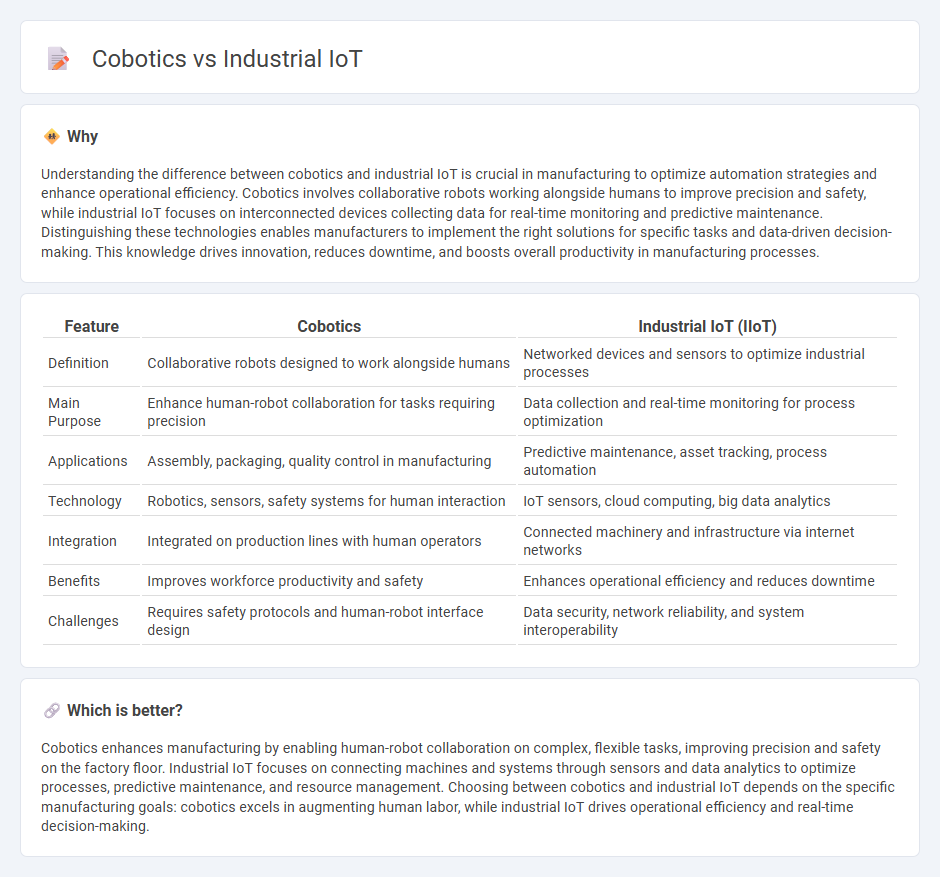

Understanding the difference between cobotics and industrial IoT is crucial in manufacturing to optimize automation strategies and enhance operational efficiency. Cobotics involves collaborative robots working alongside humans to improve precision and safety, while industrial IoT focuses on interconnected devices collecting data for real-time monitoring and predictive maintenance. Distinguishing these technologies enables manufacturers to implement the right solutions for specific tasks and data-driven decision-making. This knowledge drives innovation, reduces downtime, and boosts overall productivity in manufacturing processes.

Comparison Table

| Feature | Cobotics | Industrial IoT (IIoT) |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans | Networked devices and sensors to optimize industrial processes |

| Main Purpose | Enhance human-robot collaboration for tasks requiring precision | Data collection and real-time monitoring for process optimization |

| Applications | Assembly, packaging, quality control in manufacturing | Predictive maintenance, asset tracking, process automation |

| Technology | Robotics, sensors, safety systems for human interaction | IoT sensors, cloud computing, big data analytics |

| Integration | Integrated on production lines with human operators | Connected machinery and infrastructure via internet networks |

| Benefits | Improves workforce productivity and safety | Enhances operational efficiency and reduces downtime |

| Challenges | Requires safety protocols and human-robot interface design | Data security, network reliability, and system interoperability |

Which is better?

Cobotics enhances manufacturing by enabling human-robot collaboration on complex, flexible tasks, improving precision and safety on the factory floor. Industrial IoT focuses on connecting machines and systems through sensors and data analytics to optimize processes, predictive maintenance, and resource management. Choosing between cobotics and industrial IoT depends on the specific manufacturing goals: cobotics excels in augmenting human labor, while industrial IoT drives operational efficiency and real-time decision-making.

Connection

Cobotics enhances manufacturing efficiency by enabling collaborative robots to work safely alongside humans, while industrial IoT provides real-time data connectivity that optimizes machine performance and predictive maintenance. The integration of cobots with IoT sensors allows seamless data exchange, leading to adaptive automation and reduced downtime. This interconnected system drives smart factory ecosystems, improving production quality and operational agility.

Key Terms

Sensors & Connectivity

Industrial IoT leverages advanced sensors such as temperature, pressure, and vibration monitors to enable real-time data collection and remote connectivity across manufacturing environments. Cobotics uses proximity and force sensors to ensure safe, precise interaction between humans and robots, enhancing collaborative workflows within production lines. Discover how integrating sensor technology and connectivity advances efficiency and safety in modern industry.

Human-Robot Collaboration

Industrial IoT integrates sensors, devices, and data analytics to optimize manufacturing processes, enhancing machine-to-machine communication and overall operational efficiency. Cobotics emphasizes Human-Robot Collaboration (HRC), where collaborative robots (cobots) work alongside human operators to improve task flexibility, safety, and precision. Explore the key differences and benefits of these technologies to unlock the future of smart manufacturing.

Data Analytics

Industrial IoT leverages interconnected sensors and devices to collect vast amounts of real-time data from machinery, enabling predictive maintenance and operational efficiency through advanced data analytics platforms. Cobotics, featuring collaborative robots with embedded sensors, relies on data analytics to enhance human-robot interaction, improve safety, and optimize workflow in shared workspaces. Explore how integrating data analytics in industrial IoT and cobotics drives smarter manufacturing processes and unlocks new productivity gains.

Source and External Links

Industrial IoT | Digital Transformation - AWS - Industrial IoT connects machines, cloud computing, analytics, and people to digitize processes, optimize performance, and reduce waste across industries like manufacturing, energy, and agriculture.

What is industrial IoT - Arm - Industrial IoT enables real-time monitoring, control, and optimization of industrial processes and supply chains by connecting high-performance, low-energy devices operating in challenging environments.

What is IIoT (Industrial Internet of Things)? | Definition from TechTarget - IIoT is a network of intelligent devices that collect, exchange, and analyze data to improve efficiency and reliability in manufacturing and other industrial processes.

dowidth.com

dowidth.com