Generative design leverages algorithms and AI to create optimized product structures based on performance criteria, enabling innovative solutions that traditional methods may overlook. Feature-based modeling uses predefined shapes and features to build CAD models, offering precise control and ease of modifications. Explore the advantages and applications of both approaches to enhance your manufacturing design process.

Why it is important

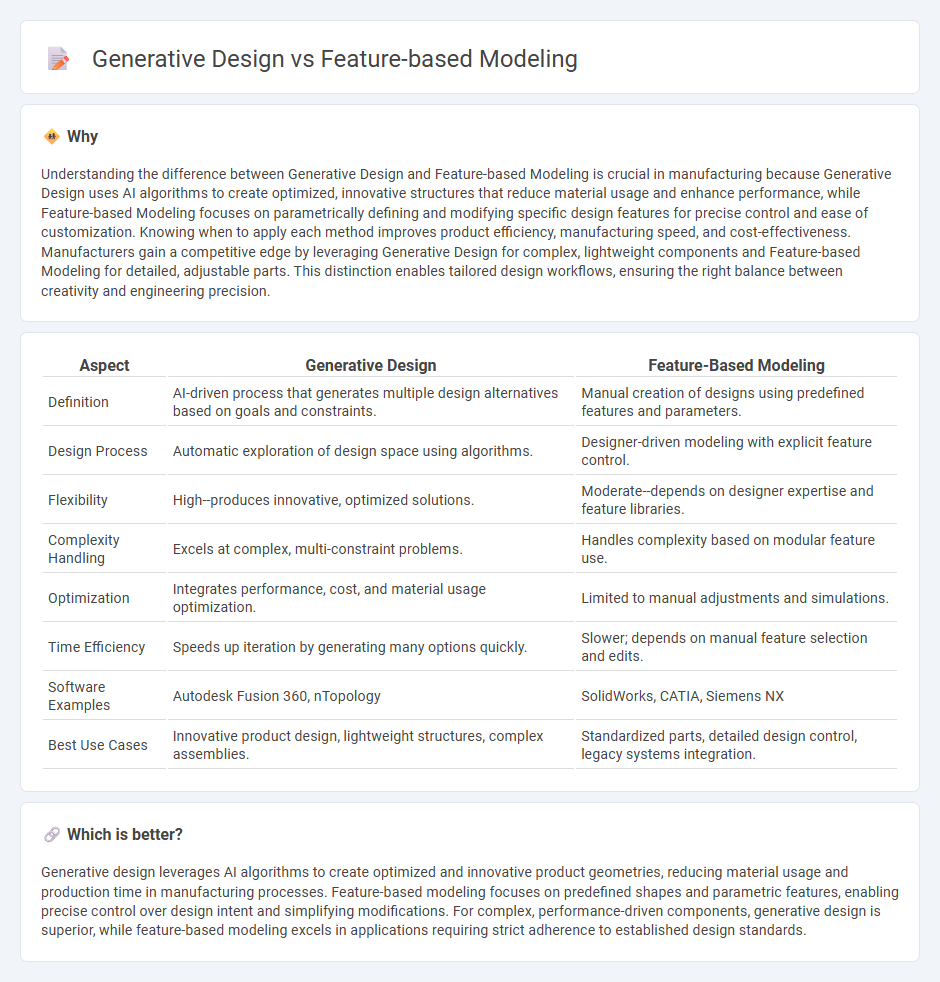

Understanding the difference between Generative Design and Feature-based Modeling is crucial in manufacturing because Generative Design uses AI algorithms to create optimized, innovative structures that reduce material usage and enhance performance, while Feature-based Modeling focuses on parametrically defining and modifying specific design features for precise control and ease of customization. Knowing when to apply each method improves product efficiency, manufacturing speed, and cost-effectiveness. Manufacturers gain a competitive edge by leveraging Generative Design for complex, lightweight components and Feature-based Modeling for detailed, adjustable parts. This distinction enables tailored design workflows, ensuring the right balance between creativity and engineering precision.

Comparison Table

| Aspect | Generative Design | Feature-Based Modeling |

|---|---|---|

| Definition | AI-driven process that generates multiple design alternatives based on goals and constraints. | Manual creation of designs using predefined features and parameters. |

| Design Process | Automatic exploration of design space using algorithms. | Designer-driven modeling with explicit feature control. |

| Flexibility | High--produces innovative, optimized solutions. | Moderate--depends on designer expertise and feature libraries. |

| Complexity Handling | Excels at complex, multi-constraint problems. | Handles complexity based on modular feature use. |

| Optimization | Integrates performance, cost, and material usage optimization. | Limited to manual adjustments and simulations. |

| Time Efficiency | Speeds up iteration by generating many options quickly. | Slower; depends on manual feature selection and edits. |

| Software Examples | Autodesk Fusion 360, nTopology | SolidWorks, CATIA, Siemens NX |

| Best Use Cases | Innovative product design, lightweight structures, complex assemblies. | Standardized parts, detailed design control, legacy systems integration. |

Which is better?

Generative design leverages AI algorithms to create optimized and innovative product geometries, reducing material usage and production time in manufacturing processes. Feature-based modeling focuses on predefined shapes and parametric features, enabling precise control over design intent and simplifying modifications. For complex, performance-driven components, generative design is superior, while feature-based modeling excels in applications requiring strict adherence to established design standards.

Connection

Generative design leverages algorithms to create optimized manufacturing models by exploring numerous design variations based on specific constraints and goals. Feature-based modeling supports this process by breaking down complex parts into modular, parametric features that can be easily modified and analyzed. Together, they enhance product innovation, reduce development time, and improve manufacturing efficiency through precise and adaptable design workflows.

Key Terms

Parametric features

Feature-based modeling relies on predefined parametric features such as holes, slots, and fillets, enabling precise control over geometry modifications through editable parameters. Generative design uses algorithms and constraints to automatically generate optimized designs, often resulting in complex, organic shapes not easily achievable with traditional parametric features. Explore in-depth insights on how parametric features influence efficiency and innovation by learning more about each approach.

Algorithm-driven optimization

Feature-based modeling relies on predefined geometry and explicit design intent, allowing precise control over individual components and standard features within CAD software. Generative design utilizes algorithm-driven optimization to explore numerous design alternatives based on constraints, objectives, and performance criteria, often producing innovative and efficient solutions beyond conventional methods. Discover how these approaches transform engineering workflows by unlocking new possibilities in product development and design efficiency.

Design automation

Feature-based modeling leverages predefined geometric features and parametric constraints to create and modify CAD models, enabling precise control and efficient iteration in design automation processes. Generative design employs artificial intelligence and computational algorithms to explore numerous design alternatives based on performance criteria, optimizing complex structures beyond traditional constraints. Explore how these methodologies transform design automation workflows and innovation by learning more about their applications and benefits.

Source and External Links

The Features of Feature-Based Modeling - Machine Design - Feature-based modeling constructs geometries by combining engineering features like holes or slots instead of basic geometric shapes, making models more easily editable and adaptable.

The Power of Feature-Based Modeling - Number Analytics - Feature-based modeling streamlines the CAD design process by breaking down complex parts into reusable, easily modifiable features, improving efficiency, collaboration, and interoperability between systems.

Feature-Based Design Overview - YouTube - In feature-based design, 3D models are built by applying features like extrude, revolve, or sweep to 2D sketches, with a feature tree recording the construction history for straightforward editing and propagation of changes.

dowidth.com

dowidth.com