Dark factories leverage advanced automation and robotics to operate with minimal human intervention, enhancing precision and reducing operational costs. Continuous manufacturing streamlines production processes by maintaining an uninterrupted flow, improving efficiency and product consistency. Explore the advantages and implementation strategies of dark factory and continuous manufacturing to optimize industrial operations.

Why it is important

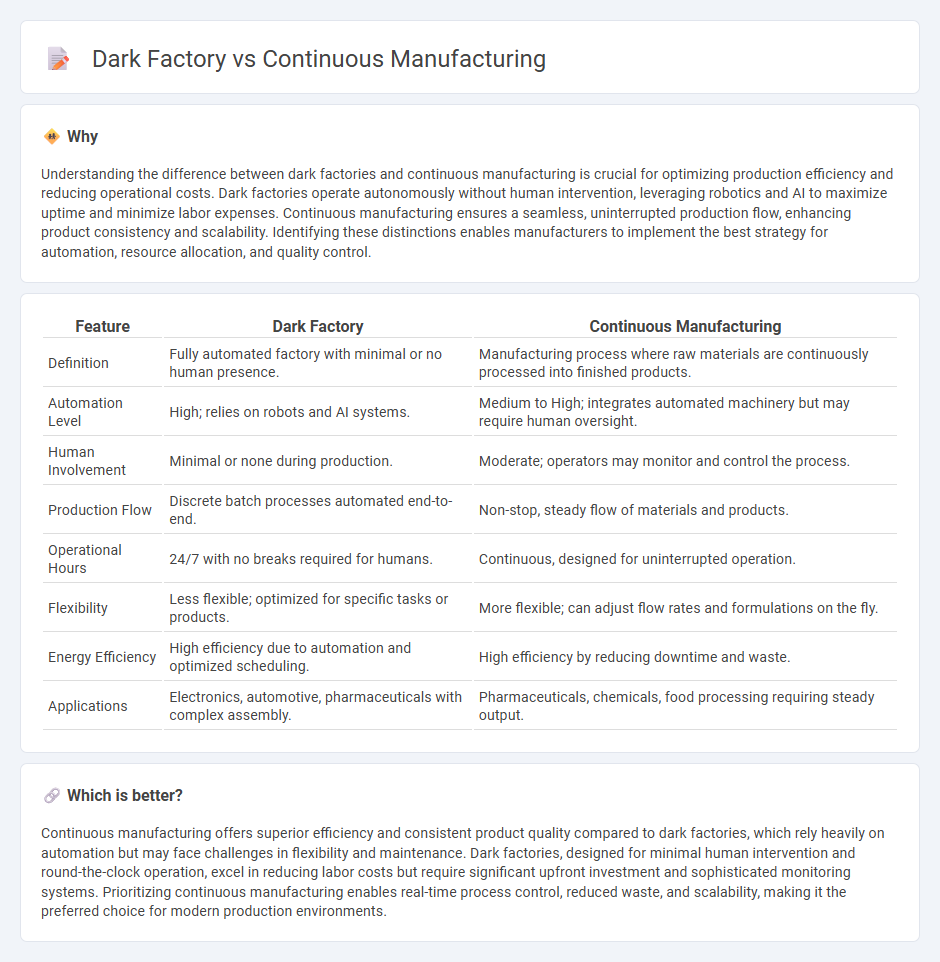

Understanding the difference between dark factories and continuous manufacturing is crucial for optimizing production efficiency and reducing operational costs. Dark factories operate autonomously without human intervention, leveraging robotics and AI to maximize uptime and minimize labor expenses. Continuous manufacturing ensures a seamless, uninterrupted production flow, enhancing product consistency and scalability. Identifying these distinctions enables manufacturers to implement the best strategy for automation, resource allocation, and quality control.

Comparison Table

| Feature | Dark Factory | Continuous Manufacturing |

|---|---|---|

| Definition | Fully automated factory with minimal or no human presence. | Manufacturing process where raw materials are continuously processed into finished products. |

| Automation Level | High; relies on robots and AI systems. | Medium to High; integrates automated machinery but may require human oversight. |

| Human Involvement | Minimal or none during production. | Moderate; operators may monitor and control the process. |

| Production Flow | Discrete batch processes automated end-to-end. | Non-stop, steady flow of materials and products. |

| Operational Hours | 24/7 with no breaks required for humans. | Continuous, designed for uninterrupted operation. |

| Flexibility | Less flexible; optimized for specific tasks or products. | More flexible; can adjust flow rates and formulations on the fly. |

| Energy Efficiency | High efficiency due to automation and optimized scheduling. | High efficiency by reducing downtime and waste. |

| Applications | Electronics, automotive, pharmaceuticals with complex assembly. | Pharmaceuticals, chemicals, food processing requiring steady output. |

Which is better?

Continuous manufacturing offers superior efficiency and consistent product quality compared to dark factories, which rely heavily on automation but may face challenges in flexibility and maintenance. Dark factories, designed for minimal human intervention and round-the-clock operation, excel in reducing labor costs but require significant upfront investment and sophisticated monitoring systems. Prioritizing continuous manufacturing enables real-time process control, reduced waste, and scalability, making it the preferred choice for modern production environments.

Connection

Dark factories utilize automation and robotics to operate with minimal human intervention, enhancing efficiency and reducing errors in continuous manufacturing processes. Continuous manufacturing relies on uninterrupted production lines, which are optimized through dark factory technologies to maintain consistent quality and throughput. Integration of dark factory systems in continuous manufacturing enables real-time monitoring and adaptive control, driving higher productivity and cost savings.

Key Terms

Automation

Continuous manufacturing leverages automated production lines to enable nonstop, efficient output with minimal human intervention, enhancing scalability and reducing operational costs. Dark factories take automation further by operating entirely without on-site human presence, using robots and AI for real-time process control, monitoring, and maintenance in a fully autonomous environment. Explore the advancements in automation driving these innovative manufacturing approaches to optimize production efficiency.

Human Intervention

Continuous manufacturing minimizes human intervention by automating production processes to ensure consistent output and reduce errors, enhancing efficiency and product quality. In contrast, dark factories operate with no or minimal human presence on-site, relying heavily on robotics and AI to perform all manufacturing tasks autonomously in controlled environments. Explore how these automation strategies reshape workforce roles and operational dynamics in modern industry.

Production Flexibility

Continuous manufacturing ensures steady, efficient output with limited variation, optimizing processes for high-volume production and minimizing downtime. Dark factories, operating autonomously without human presence, offer exceptional production flexibility by quickly adapting to changing product demands through advanced robotics and AI-driven systems. Explore how these innovative approaches can enhance manufacturing adaptability and efficiency in your operations.

Source and External Links

Continuous Manufacturing and How To Do It - Katana Cloud Inventory - Continuous manufacturing is a 24/7 production process where raw materials (gases, liquids, powders) are continuously processed in one location to produce finished products without interruption, common in industries like oil refining and pharmaceuticals.

Continuous Manufacturing: Batch to the Future - Continuous manufacturing improves drug quality by shortening production time, reducing human error through automation, enabling proactive maintenance, and allowing flexible batch sizes to minimize waste and shortages.

Continuous production - Wikipedia - Continuous production is a flow method operating nearly nonstop to process materials undergoing chemical or mechanical treatment, contrasting with batch production, often running for years without shutdowns.

dowidth.com

dowidth.com