Digital thread integrates data flow across all manufacturing stages, enabling real-time visibility and decision-making, while Product Lifecycle Management (PLM) focuses on managing product data and processes throughout the product's lifespan. By connecting engineering, production, and service data, the digital thread enhances collaboration and traceability beyond traditional PLM capabilities. Discover how these technologies transform manufacturing workflows and product innovation.

Why it is important

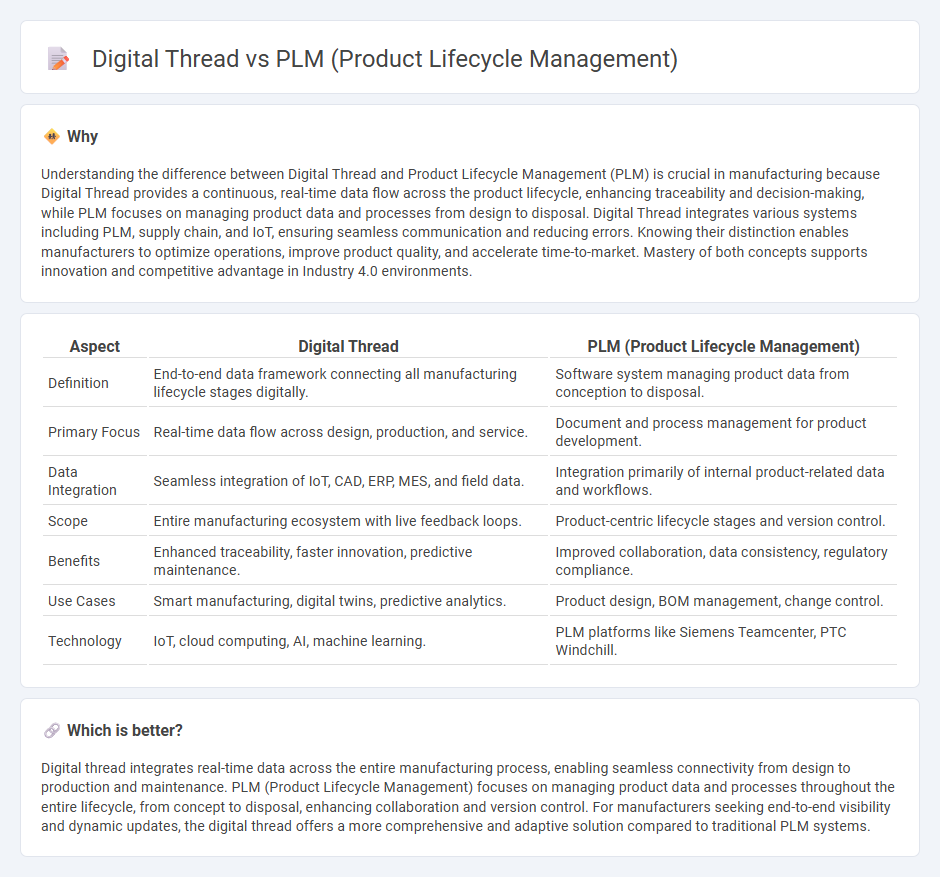

Understanding the difference between Digital Thread and Product Lifecycle Management (PLM) is crucial in manufacturing because Digital Thread provides a continuous, real-time data flow across the product lifecycle, enhancing traceability and decision-making, while PLM focuses on managing product data and processes from design to disposal. Digital Thread integrates various systems including PLM, supply chain, and IoT, ensuring seamless communication and reducing errors. Knowing their distinction enables manufacturers to optimize operations, improve product quality, and accelerate time-to-market. Mastery of both concepts supports innovation and competitive advantage in Industry 4.0 environments.

Comparison Table

| Aspect | Digital Thread | PLM (Product Lifecycle Management) |

|---|---|---|

| Definition | End-to-end data framework connecting all manufacturing lifecycle stages digitally. | Software system managing product data from conception to disposal. |

| Primary Focus | Real-time data flow across design, production, and service. | Document and process management for product development. |

| Data Integration | Seamless integration of IoT, CAD, ERP, MES, and field data. | Integration primarily of internal product-related data and workflows. |

| Scope | Entire manufacturing ecosystem with live feedback loops. | Product-centric lifecycle stages and version control. |

| Benefits | Enhanced traceability, faster innovation, predictive maintenance. | Improved collaboration, data consistency, regulatory compliance. |

| Use Cases | Smart manufacturing, digital twins, predictive analytics. | Product design, BOM management, change control. |

| Technology | IoT, cloud computing, AI, machine learning. | PLM platforms like Siemens Teamcenter, PTC Windchill. |

Which is better?

Digital thread integrates real-time data across the entire manufacturing process, enabling seamless connectivity from design to production and maintenance. PLM (Product Lifecycle Management) focuses on managing product data and processes throughout the entire lifecycle, from concept to disposal, enhancing collaboration and version control. For manufacturers seeking end-to-end visibility and dynamic updates, the digital thread offers a more comprehensive and adaptive solution compared to traditional PLM systems.

Connection

Digital thread integrates data flow across the entire manufacturing process, creating a unified view of product information that enhances traceability, quality, and collaboration. PLM (Product Lifecycle Management) serves as the platform that manages this continuous data stream, ensuring accurate version control, design consistency, and regulatory compliance throughout a product's lifecycle. Together, they optimize decision-making and accelerate innovation by linking design, production, and service data in a seamless digital ecosystem.

Key Terms

Data Integration

Product Lifecycle Management (PLM) centralizes product data to streamline design, manufacturing, and maintenance processes, ensuring consistent information across departments. The digital thread extends beyond PLM by connecting data flows across the entire product lifecycle, including supply chain and customer feedback, enabling real-time visibility and traceability. Discover how integrating PLM with the digital thread can enhance data coherence and operational efficiency.

Product Traceability

PLM systems centralize product data management and version control across the entire product lifecycle, ensuring consistent documentation and design traceability. The digital thread integrates real-time data from PLM, manufacturing, supply chain, and service systems to create a continuous, traceable flow of product information across all stages. Explore how combining PLM and the digital thread enhances product traceability and drives more efficient lifecycle management.

Collaboration

PLM (Product Lifecycle Management) systems centralize data and processes to enhance team collaboration across product design, manufacturing, and service stages by providing a unified platform for version control and workflow management. The digital thread links data streams across the entire product lifecycle in real-time, enabling seamless communication and traceability between design, production, and support functions. Explore how integrating PLM with the digital thread drives innovation and efficiency in collaborative product development.

Source and External Links

What Is Product Lifecycle Management? - IBM - PLM is a strategic approach that manages product lifecycles end to end, integrating people, data, processes, and business systems to enable collaboration and optimize production from concept to disposal, helping companies reduce costs and maximize profits.

What Is PLM Software? | Product Lifecycle Management - Oracle - PLM software manages all information and processes across a product's lifecycle globally, serving as a digital foundation to unify product value chains, accelerate innovation, and improve product design, manufacturing, and service.

Product Life Cycle Management (PLM) Explained - Atlassian - PLM integrates information, processes, and people across phases such as design and development, manufacturing, and distribution, ensuring alignment with market needs and operational coordination for product success.

dowidth.com

dowidth.com