Biofabrication leverages biological materials such as cells, biomolecules, and tissues to create complex structures with applications in tissue engineering and regenerative medicine. Nanofabrication involves manipulating matter at the atomic and molecular scale, primarily using techniques like electron beam lithography and atomic layer deposition to produce nanoscale devices and components. Explore the distinctions and innovations driving these advanced manufacturing processes for cutting-edge technological advancements.

Why it is important

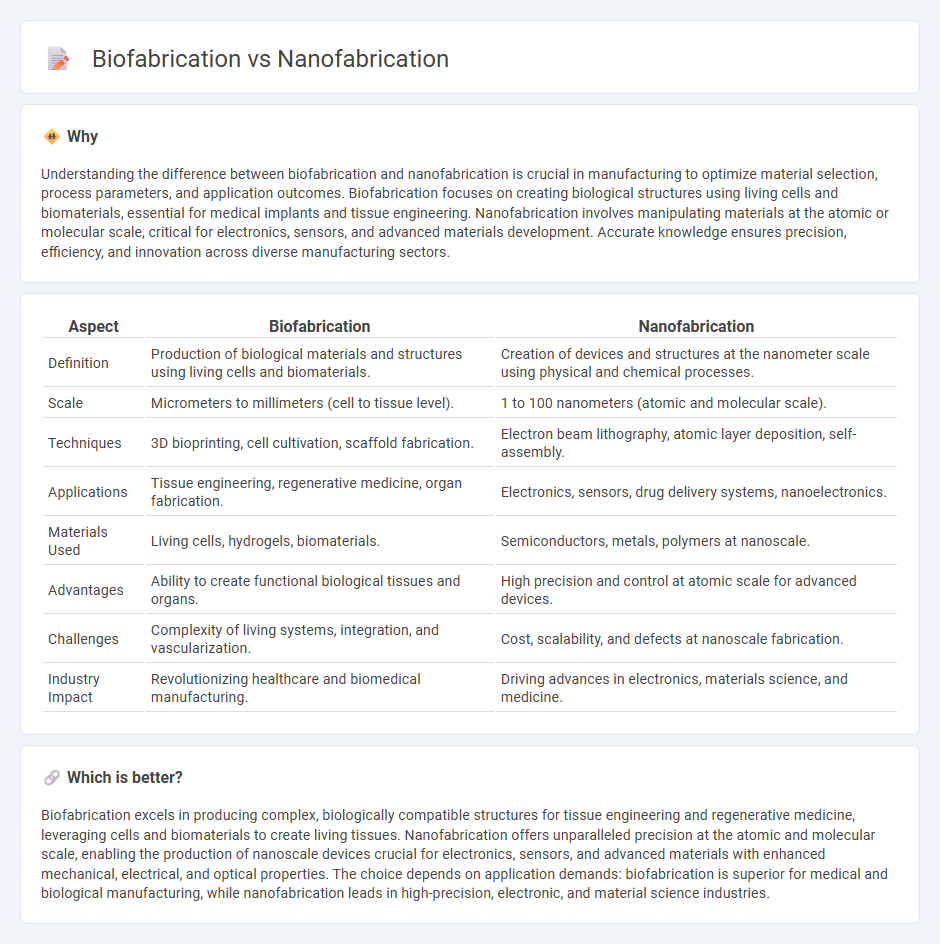

Understanding the difference between biofabrication and nanofabrication is crucial in manufacturing to optimize material selection, process parameters, and application outcomes. Biofabrication focuses on creating biological structures using living cells and biomaterials, essential for medical implants and tissue engineering. Nanofabrication involves manipulating materials at the atomic or molecular scale, critical for electronics, sensors, and advanced materials development. Accurate knowledge ensures precision, efficiency, and innovation across diverse manufacturing sectors.

Comparison Table

| Aspect | Biofabrication | Nanofabrication |

|---|---|---|

| Definition | Production of biological materials and structures using living cells and biomaterials. | Creation of devices and structures at the nanometer scale using physical and chemical processes. |

| Scale | Micrometers to millimeters (cell to tissue level). | 1 to 100 nanometers (atomic and molecular scale). |

| Techniques | 3D bioprinting, cell cultivation, scaffold fabrication. | Electron beam lithography, atomic layer deposition, self-assembly. |

| Applications | Tissue engineering, regenerative medicine, organ fabrication. | Electronics, sensors, drug delivery systems, nanoelectronics. |

| Materials Used | Living cells, hydrogels, biomaterials. | Semiconductors, metals, polymers at nanoscale. |

| Advantages | Ability to create functional biological tissues and organs. | High precision and control at atomic scale for advanced devices. |

| Challenges | Complexity of living systems, integration, and vascularization. | Cost, scalability, and defects at nanoscale fabrication. |

| Industry Impact | Revolutionizing healthcare and biomedical manufacturing. | Driving advances in electronics, materials science, and medicine. |

Which is better?

Biofabrication excels in producing complex, biologically compatible structures for tissue engineering and regenerative medicine, leveraging cells and biomaterials to create living tissues. Nanofabrication offers unparalleled precision at the atomic and molecular scale, enabling the production of nanoscale devices crucial for electronics, sensors, and advanced materials with enhanced mechanical, electrical, and optical properties. The choice depends on application demands: biofabrication is superior for medical and biological manufacturing, while nanofabrication leads in high-precision, electronic, and material science industries.

Connection

Biofabrication and nanofabrication intersect through their shared use of advanced materials and precise control at micro and nanoscale levels to create complex structures for manufacturing applications. Both techniques enable the production of highly detailed, functional components essential for biomedical devices, tissue engineering, and smart materials. Integration of biofabrication with nanofabrication enhances the development of innovative products with improved mechanical properties and biological functionality.

Key Terms

Lithography

Nanofabrication employs lithography techniques such as electron-beam lithography and nanoimprint lithography to create structures at the nanoscale with high precision for use in electronics and photonics. Biofabrication uses lithography methods adapted for biological applications, including patterning of cells and biomolecules on substrates to engineer tissue scaffolds and microenvironments. Discover how lithography bridges these fields by enabling precise patterning crucial for advances in nanotechnology and regenerative medicine.

Bioprinting

Nanofabrication involves the manipulation of materials at the nanoscale to create devices with precise structural features, whereas biofabrication integrates living cells, biomaterials, and biomolecules to engineer functional biological tissues. Bioprinting, a key technique in biofabrication, utilizes 3D printing technology to layer cells and biomaterials, resembling natural tissue architecture for applications in regenerative medicine and drug testing. Explore the latest advancements in bioprinting technologies and their transformative impact on personalized healthcare.

Self-assembly

Nanofabrication involves the precise arrangement of materials at the nanoscale using techniques like lithography and self-assembly, enabling the creation of complex nanostructures for electronics and photonics. Biofabrication employs biological components and processes, including self-assembly of biomolecules and cells, to engineer tissues and organs with applications in regenerative medicine. Explore the interplay of self-assembly mechanisms in nanofabrication and biofabrication to understand how molecular interactions drive innovation across these fields.

Source and External Links

Nanomanufacturing - Wikipedia - Nanofabrication involves producing nanoscaled materials or parts "bottom up," using methods like the Nanoscale Offset Printing System (NanoOps) to print nanoscale structures economically and rapidly, applicable in electronics, medicine, and energy conservation.

Micro- and nanofabrication methods in nanotechnological medical applications - Nanofabrication employs techniques such as photolithography, soft lithography, rapid prototyping, and CAD-driven additive processes like 3D printing and selective laser sintering to create complex nanoscale structures efficiently.

Nanofabrication - Harvard CNS - Advanced nanofabrication facilities provide capabilities including e-beam and optical lithography, atomic layer deposition, and reactive ion etching for fabricating nanoscale devices from diverse novel materials in cleanroom environments.

dowidth.com

dowidth.com