Closed-loop manufacturing integrates real-time feedback and automation to continuously optimize production processes, reducing waste and enhancing product quality. Just-in-time manufacturing focuses on minimizing inventory by producing goods only as they are needed, ensuring efficiency and cost savings. Explore the benefits and differences between these advanced manufacturing strategies for improved operational performance.

Why it is important

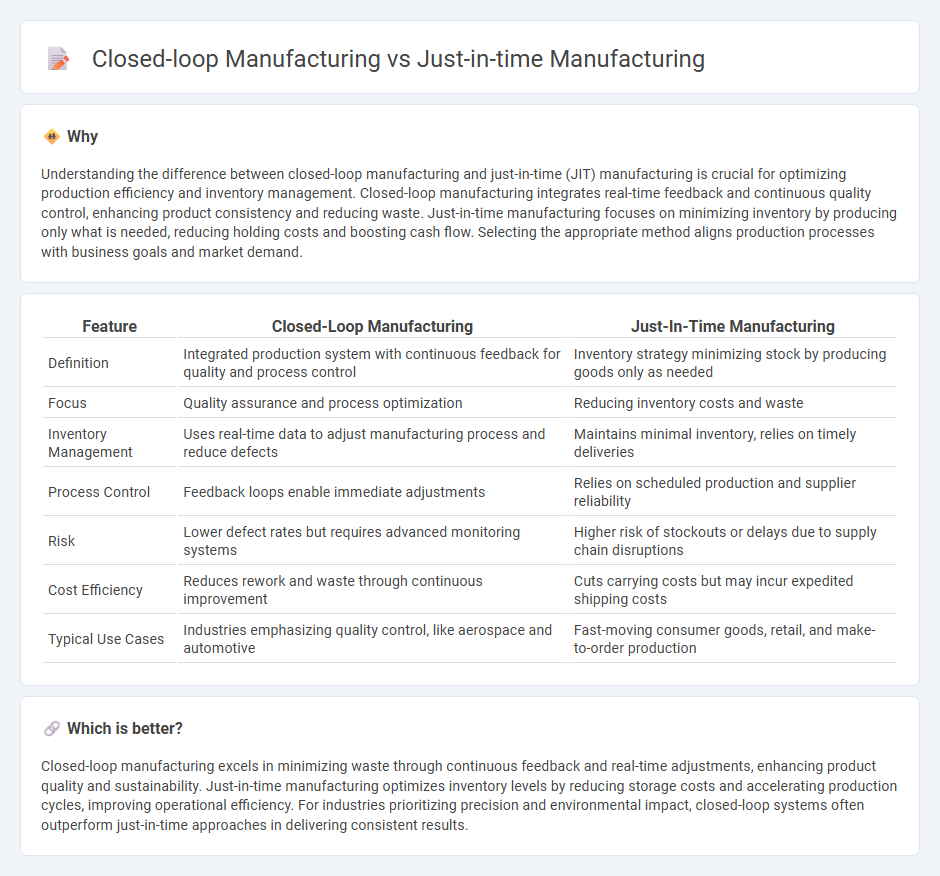

Understanding the difference between closed-loop manufacturing and just-in-time (JIT) manufacturing is crucial for optimizing production efficiency and inventory management. Closed-loop manufacturing integrates real-time feedback and continuous quality control, enhancing product consistency and reducing waste. Just-in-time manufacturing focuses on minimizing inventory by producing only what is needed, reducing holding costs and boosting cash flow. Selecting the appropriate method aligns production processes with business goals and market demand.

Comparison Table

| Feature | Closed-Loop Manufacturing | Just-In-Time Manufacturing |

|---|---|---|

| Definition | Integrated production system with continuous feedback for quality and process control | Inventory strategy minimizing stock by producing goods only as needed |

| Focus | Quality assurance and process optimization | Reducing inventory costs and waste |

| Inventory Management | Uses real-time data to adjust manufacturing process and reduce defects | Maintains minimal inventory, relies on timely deliveries |

| Process Control | Feedback loops enable immediate adjustments | Relies on scheduled production and supplier reliability |

| Risk | Lower defect rates but requires advanced monitoring systems | Higher risk of stockouts or delays due to supply chain disruptions |

| Cost Efficiency | Reduces rework and waste through continuous improvement | Cuts carrying costs but may incur expedited shipping costs |

| Typical Use Cases | Industries emphasizing quality control, like aerospace and automotive | Fast-moving consumer goods, retail, and make-to-order production |

Which is better?

Closed-loop manufacturing excels in minimizing waste through continuous feedback and real-time adjustments, enhancing product quality and sustainability. Just-in-time manufacturing optimizes inventory levels by reducing storage costs and accelerating production cycles, improving operational efficiency. For industries prioritizing precision and environmental impact, closed-loop systems often outperform just-in-time approaches in delivering consistent results.

Connection

Closed-loop manufacturing enhances Just-in-time (JIT) manufacturing by continuously monitoring production processes and feeding real-time data back into the system for immediate adjustments. This integration minimizes inventory levels and reduces waste by ensuring components arrive precisely when needed based on accurate feedback. The synergy between closed-loop control and JIT accelerates responsiveness and efficiency across production workflows.

Key Terms

Inventory Management

Just-in-time manufacturing minimizes inventory levels by receiving materials only as needed, reducing waste and storage costs. Closed-loop manufacturing incorporates real-time feedback and automated systems to optimize inventory replenishment and improve demand forecasting accuracy. Explore how these methods revolutionize inventory management for enhanced operational efficiency.

Feedback Control Systems

Just-in-time manufacturing minimizes inventory by synchronizing production closely with demand, while closed-loop manufacturing integrates real-time feedback control systems to continuously monitor and adjust processes for optimal efficiency. Feedback control systems in closed-loop manufacturing enhance precision, reduce waste, and improve product quality by using sensor data and automated adjustments. Discover how feedback control systems revolutionize manufacturing efficiency and quality through detailed insights.

Waste Reduction

Just-in-time manufacturing minimizes inventory by producing goods only when needed, significantly reducing excess materials and waste accumulation. Closed-loop manufacturing enhances sustainability by recycling waste materials back into the production cycle, effectively minimizing landfill contributions and resource consumption. Explore the differences and benefits of both systems to optimize your waste reduction strategy.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just-in-time (JIT) manufacturing is a production strategy designed to reduce inventory costs and waste by producing goods only as needed, improving efficiency, flexibility, and product quality through continuous monitoring and close supplier collaboration.

Lean manufacturing - Wikipedia - JIT manufacturing matches production to customer demand, emphasizing efficiency and minimal inventory, and incorporates methodologies like setup reduction, preventive maintenance, and pull systems (kanban) to streamline operations.

What is just-in-time manufacturing (JIT manufacturing)? - TechTarget - JIT manufacturing is a model where items are created strictly to meet current demand, eliminating overproduction, excess inventory, and other forms of waste to increase efficiency and reduce costs.

dowidth.com

dowidth.com