Biofabrication involves the layer-by-layer construction of biological materials to create complex tissue structures, utilizing techniques such as 3D bioprinting and cell encapsulation. Subtractive manufacturing, by contrast, relies on removing material from a solid block through methods like CNC machining or laser cutting to shape precise components. Explore the advantages and applications of each manufacturing approach to understand their impact on modern production.

Why it is important

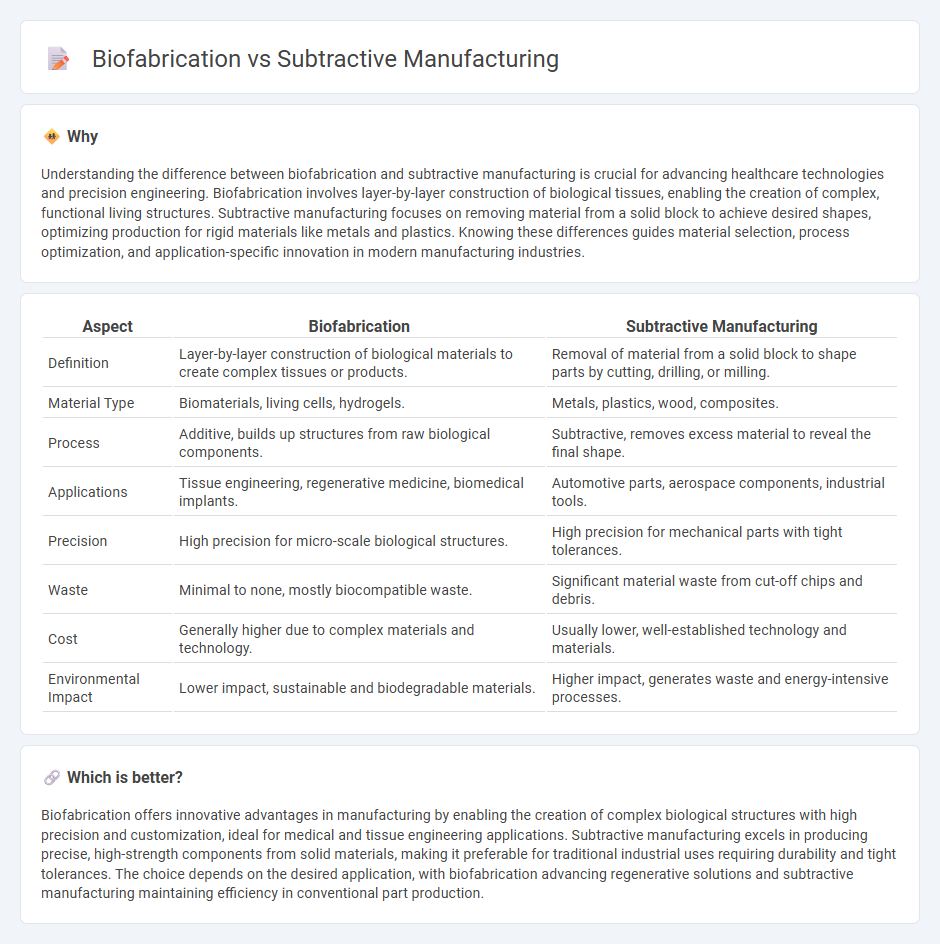

Understanding the difference between biofabrication and subtractive manufacturing is crucial for advancing healthcare technologies and precision engineering. Biofabrication involves layer-by-layer construction of biological tissues, enabling the creation of complex, functional living structures. Subtractive manufacturing focuses on removing material from a solid block to achieve desired shapes, optimizing production for rigid materials like metals and plastics. Knowing these differences guides material selection, process optimization, and application-specific innovation in modern manufacturing industries.

Comparison Table

| Aspect | Biofabrication | Subtractive Manufacturing |

|---|---|---|

| Definition | Layer-by-layer construction of biological materials to create complex tissues or products. | Removal of material from a solid block to shape parts by cutting, drilling, or milling. |

| Material Type | Biomaterials, living cells, hydrogels. | Metals, plastics, wood, composites. |

| Process | Additive, builds up structures from raw biological components. | Subtractive, removes excess material to reveal the final shape. |

| Applications | Tissue engineering, regenerative medicine, biomedical implants. | Automotive parts, aerospace components, industrial tools. |

| Precision | High precision for micro-scale biological structures. | High precision for mechanical parts with tight tolerances. |

| Waste | Minimal to none, mostly biocompatible waste. | Significant material waste from cut-off chips and debris. |

| Cost | Generally higher due to complex materials and technology. | Usually lower, well-established technology and materials. |

| Environmental Impact | Lower impact, sustainable and biodegradable materials. | Higher impact, generates waste and energy-intensive processes. |

Which is better?

Biofabrication offers innovative advantages in manufacturing by enabling the creation of complex biological structures with high precision and customization, ideal for medical and tissue engineering applications. Subtractive manufacturing excels in producing precise, high-strength components from solid materials, making it preferable for traditional industrial uses requiring durability and tight tolerances. The choice depends on the desired application, with biofabrication advancing regenerative solutions and subtractive manufacturing maintaining efficiency in conventional part production.

Connection

Biofabrication harnesses subtractive manufacturing techniques such as laser ablation and milling to precisely remove material from biomaterials, enabling the creation of intricate biological structures. Subtractive processes enhance the spatial resolution and structural fidelity in tissue engineering and regenerative medicine applications. Integration of these methods facilitates scalable production of complex, functional biological constructs with controlled micro-architectures.

Key Terms

Material removal

Subtractive manufacturing involves precise material removal techniques such as milling, turning, or laser cutting to shape components, often resulting in significant waste of raw materials. In contrast, biofabrication employs additive processes like 3D bioprinting to layer biological materials with minimal waste, prioritizing cell viability and complex tissue structures. Explore how material removal impacts efficiency and sustainability in advanced manufacturing technologies.

Bioprinting

Subtractive manufacturing involves removing material from a solid block to create a desired shape, commonly used in traditional machining processes, while biofabrication, specifically bioprinting, builds living tissues layer-by-layer using bioinks composed of cells and biomaterials. Bioprinting advances regenerative medicine by enabling precise spatial placement of multiple cell types, closely mimicking natural tissue architecture not achievable with subtractive methods. Explore how bioprinting transforms tissue engineering and medical applications for deeper insights.

Scaffold

Subtractive manufacturing sculpts scaffolds by removing material from a solid block, enabling precise control over geometry and mechanical properties ideal for bone and cartilage tissue engineering. Biofabrication builds scaffolds layer-by-layer through techniques like 3D bioprinting, allowing incorporation of living cells and biomaterials to closely mimic the native extracellular matrix. Explore the latest advancements in scaffold design to understand how these methods enhance tissue regeneration outcomes.

Source and External Links

Additive vs. Subtractive Manufacturing - Formlabs - Subtractive manufacturing is a group of processes that create parts by removing material from solid blocks or rods using CNC machining, drilling, grinding, and other cutting operations, ideal for plastics or metals requiring tight tolerances and complex geometries.

Subtractive Manufacturing vs. Additive Manufacturing | Xometry Pro - In subtractive manufacturing, material is progressively removed through cutting, drilling, or grinding from a solid block or sheet, typically via CNC machining, allowing for greater dimensional accuracy and work with a broad range of materials including metals, plastics, wood, and stone.

Subtractive Manufacturing: Past, Present, and Future - Subtractive manufacturing involves shaping and finishing materials by cutting away excess to achieve desired parts, and it remains crucial especially when combined with additive manufacturing in hybrid processes that offer precision finishing after 3D printing.

dowidth.com

dowidth.com