Collaborative robots (cobots) enhance manufacturing processes by working safely alongside human operators to perform precise, repetitive tasks, increasing efficiency and reducing errors. Autonomous mobile robots (AMRs) navigate factory floors independently, transporting materials and components to streamline logistics and minimize downtime. Discover how integrating these technologies can revolutionize your manufacturing operations and drive productivity.

Why it is important

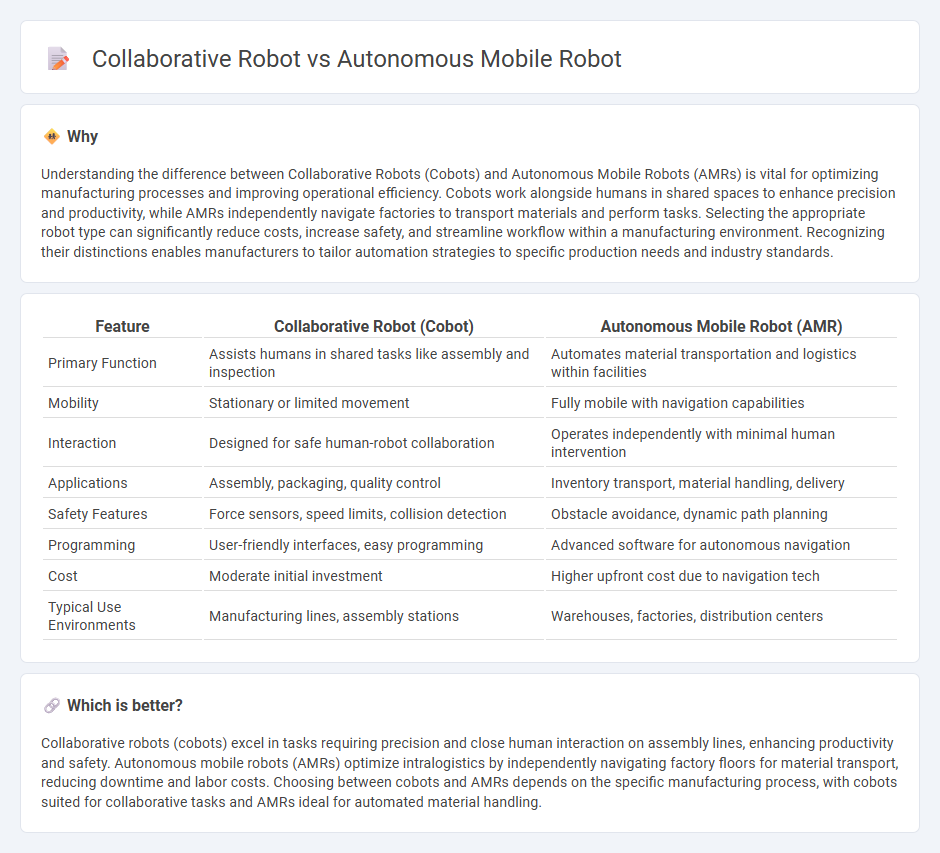

Understanding the difference between Collaborative Robots (Cobots) and Autonomous Mobile Robots (AMRs) is vital for optimizing manufacturing processes and improving operational efficiency. Cobots work alongside humans in shared spaces to enhance precision and productivity, while AMRs independently navigate factories to transport materials and perform tasks. Selecting the appropriate robot type can significantly reduce costs, increase safety, and streamline workflow within a manufacturing environment. Recognizing their distinctions enables manufacturers to tailor automation strategies to specific production needs and industry standards.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Autonomous Mobile Robot (AMR) |

|---|---|---|

| Primary Function | Assists humans in shared tasks like assembly and inspection | Automates material transportation and logistics within facilities |

| Mobility | Stationary or limited movement | Fully mobile with navigation capabilities |

| Interaction | Designed for safe human-robot collaboration | Operates independently with minimal human intervention |

| Applications | Assembly, packaging, quality control | Inventory transport, material handling, delivery |

| Safety Features | Force sensors, speed limits, collision detection | Obstacle avoidance, dynamic path planning |

| Programming | User-friendly interfaces, easy programming | Advanced software for autonomous navigation |

| Cost | Moderate initial investment | Higher upfront cost due to navigation tech |

| Typical Use Environments | Manufacturing lines, assembly stations | Warehouses, factories, distribution centers |

Which is better?

Collaborative robots (cobots) excel in tasks requiring precision and close human interaction on assembly lines, enhancing productivity and safety. Autonomous mobile robots (AMRs) optimize intralogistics by independently navigating factory floors for material transport, reducing downtime and labor costs. Choosing between cobots and AMRs depends on the specific manufacturing process, with cobots suited for collaborative tasks and AMRs ideal for automated material handling.

Connection

Collaborative robots (cobots) and autonomous mobile robots (AMRs) are interconnected in manufacturing environments through integrated automation workflows that enhance production efficiency and flexibility. Cobots perform precise, human-safe tasks such as assembly or quality inspection, while AMRs handle material transport and logistics within warehouses or factory floors. Their combined use streamlines operations by synchronizing task execution and mobile support, reducing downtime and labor costs.

Key Terms

Navigation

Autonomous mobile robots (AMRs) use advanced sensors, LiDAR, and AI-driven algorithms for independent navigation in dynamic environments, enabling obstacle avoidance and route optimization without human intervention. Collaborative robots (cobots) are designed to work alongside humans, relying on shared workspace sensors and limited autonomous navigation to maintain safety and efficiency during close-proximity tasks. Explore detailed comparisons of navigation technologies and use cases to understand which robot suits your operational needs best.

Human-robot interaction

Autonomous mobile robots (AMRs) navigate environments independently using sensors and algorithms, minimizing direct human intervention, while collaborative robots (cobots) are designed to work safely alongside humans, emphasizing intuitive interaction and shared task execution. Human-robot interaction in AMRs centers on monitoring and supervisory control, whereas cobots prioritize real-time communication, adaptive responses, and ergonomic integration to enhance teamwork and productivity. Explore detailed comparisons and insights on optimizing human-robot collaboration for your industry needs.

Safety

Autonomous mobile robots (AMRs) operate independently within dynamic environments using advanced sensors and algorithms to navigate safely, minimizing collision risks in industrial settings. Collaborative robots (cobots) are designed to work alongside humans, equipped with force sensors and emergency stop features to ensure safe interaction without barriers. Explore further to understand the safety protocols and technological innovations distinguishing AMRs from cobots in modern workplaces.

Source and External Links

Autonomous Mobile Robots (AMRs): A Guide - Autonomous mobile robots (AMRs) are robots capable of navigating their environment without human oversight, using sensors and preprogrammed mapping to perform tasks such as transporting goods in warehouses and manufacturing plants with flexibility beyond traditional automated guided vehicles (AGVs).

Automated & Autonomous Mobile Robots - AMRs autonomously perform specific tasks across various sectors like logistics and manufacturing, using advanced navigation technologies like SLAM to adapt to changing environments and collaborate with humans while providing scalability and versatile applications.

Autonomous Mobile Robots (AMRs) - ABB Robotics' AMRs are advanced transport robots designed to autonomously move loads in multiple industries, offering flexible payload capacities, smart safety features, and the ability to enhance efficiency and competitiveness in facilities such as distribution centers and production lines.

dowidth.com

dowidth.com