Servitization transforms traditional manufacturing by integrating services such as maintenance, consulting, and support, creating added value beyond the physical product. Digitalization leverages advanced technologies like IoT, AI, and cloud computing to optimize production, enhance efficiency, and enable data-driven decision-making. Explore how these strategies redefine industry operations and drive competitive advantage.

Why it is important

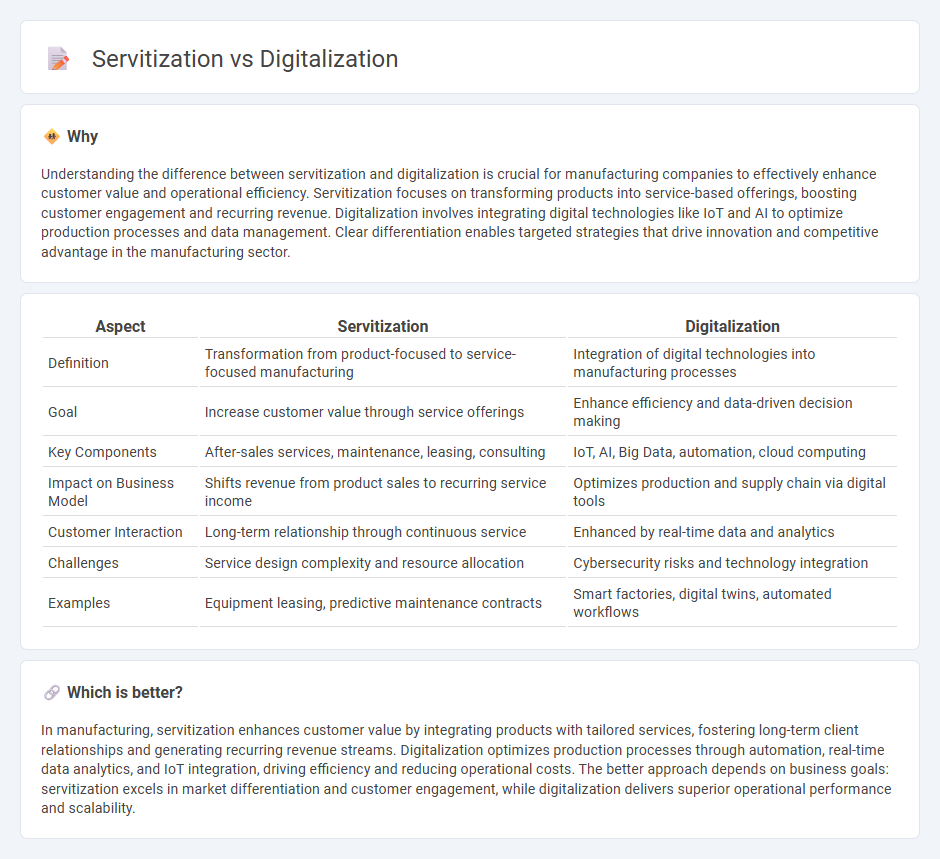

Understanding the difference between servitization and digitalization is crucial for manufacturing companies to effectively enhance customer value and operational efficiency. Servitization focuses on transforming products into service-based offerings, boosting customer engagement and recurring revenue. Digitalization involves integrating digital technologies like IoT and AI to optimize production processes and data management. Clear differentiation enables targeted strategies that drive innovation and competitive advantage in the manufacturing sector.

Comparison Table

| Aspect | Servitization | Digitalization |

|---|---|---|

| Definition | Transformation from product-focused to service-focused manufacturing | Integration of digital technologies into manufacturing processes |

| Goal | Increase customer value through service offerings | Enhance efficiency and data-driven decision making |

| Key Components | After-sales services, maintenance, leasing, consulting | IoT, AI, Big Data, automation, cloud computing |

| Impact on Business Model | Shifts revenue from product sales to recurring service income | Optimizes production and supply chain via digital tools |

| Customer Interaction | Long-term relationship through continuous service | Enhanced by real-time data and analytics |

| Challenges | Service design complexity and resource allocation | Cybersecurity risks and technology integration |

| Examples | Equipment leasing, predictive maintenance contracts | Smart factories, digital twins, automated workflows |

Which is better?

In manufacturing, servitization enhances customer value by integrating products with tailored services, fostering long-term client relationships and generating recurring revenue streams. Digitalization optimizes production processes through automation, real-time data analytics, and IoT integration, driving efficiency and reducing operational costs. The better approach depends on business goals: servitization excels in market differentiation and customer engagement, while digitalization delivers superior operational performance and scalability.

Connection

Servitization in manufacturing transforms traditional product-centric companies into service-oriented businesses, leveraging digitalization to enable real-time data analytics, predictive maintenance, and enhanced customer experiences. Digital technologies such as IoT, AI, and cloud computing facilitate the seamless integration of services with physical products, driving operational efficiency and innovation. This synergy between servitization and digitalization enhances competitive advantage by promoting value-added services and continuous customer engagement throughout the product lifecycle.

Key Terms

Industrial IoT (IIoT)

Industrial IoT (IIoT) drives digitalization by integrating smart sensors and connected devices for real-time data analytics, enhancing operational efficiency across manufacturing processes. Servitization leverages IIoT data to shift from product-centric to service-centric business models, enabling predictive maintenance, performance-based contracts, and enhanced customer experiences. Explore how IIoT transforms industries through digitalization and servitization to unlock new business value and competitive advantages.

Product-Service Systems (PSS)

Digitalization enhances Product-Service Systems (PSS) by integrating IoT, AI, and data analytics to improve real-time monitoring, predictive maintenance, and customer experience. Servitization transforms traditional product-centric businesses into service-oriented models, promoting value co-creation and sustainable competitive advantages through customized service offerings. Explore further to understand how combining digitalization with servitization revolutionizes industry operations and customer engagement.

Data-driven Business Models

Data-driven business models harness digital technologies to transform service delivery through real-time analytics, IoT integration, and customer-centric platforms, boosting operational efficiency and personalized experiences. Servitization involves shifting from product-centric to service-oriented value propositions, embedding digital tools to enable predictive maintenance and subscription-based services. Explore how combining digitalization and servitization drives innovative business strategies and sustainable growth.

Source and External Links

Digitization vs Digitalization: Real-life Examples And How to Digitize - Digitalization entails using digital tools to transform and improve business processes, integrating technology, data, and culture to boost efficiency and innovation beyond mere digitization of analog assets.

What is Digitalization? - WalkMe - Digitalization transforms business models by leveraging digital technologies to create new revenue streams and value, exemplified by companies like John Deere using connected devices to enhance operations.

Digitization vs Digitalization: Differences and Examples - Digitalization improves entire business processes using tools like CRM and ERP systems to enhance operational efficiency, distinct from digitization which is simply converting analog data into digital formats.

dowidth.com

dowidth.com