Additive manufacturing builds objects layer-by-layer directly from digital models, enabling complex geometries and rapid prototyping. In contrast, molding involves shaping materials by injecting them into pre-made molds, ideal for high-volume production with consistent repeatability. Explore the advantages and applications of each method to determine the best fit for your manufacturing needs.

Why it is important

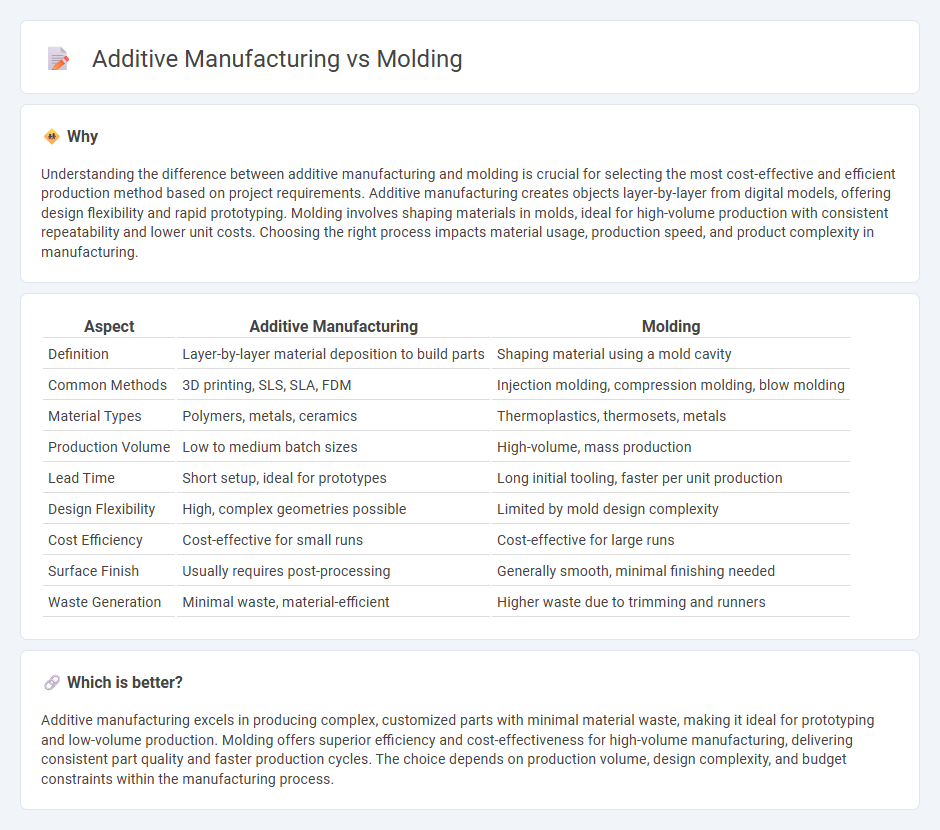

Understanding the difference between additive manufacturing and molding is crucial for selecting the most cost-effective and efficient production method based on project requirements. Additive manufacturing creates objects layer-by-layer from digital models, offering design flexibility and rapid prototyping. Molding involves shaping materials in molds, ideal for high-volume production with consistent repeatability and lower unit costs. Choosing the right process impacts material usage, production speed, and product complexity in manufacturing.

Comparison Table

| Aspect | Additive Manufacturing | Molding |

|---|---|---|

| Definition | Layer-by-layer material deposition to build parts | Shaping material using a mold cavity |

| Common Methods | 3D printing, SLS, SLA, FDM | Injection molding, compression molding, blow molding |

| Material Types | Polymers, metals, ceramics | Thermoplastics, thermosets, metals |

| Production Volume | Low to medium batch sizes | High-volume, mass production |

| Lead Time | Short setup, ideal for prototypes | Long initial tooling, faster per unit production |

| Design Flexibility | High, complex geometries possible | Limited by mold design complexity |

| Cost Efficiency | Cost-effective for small runs | Cost-effective for large runs |

| Surface Finish | Usually requires post-processing | Generally smooth, minimal finishing needed |

| Waste Generation | Minimal waste, material-efficient | Higher waste due to trimming and runners |

Which is better?

Additive manufacturing excels in producing complex, customized parts with minimal material waste, making it ideal for prototyping and low-volume production. Molding offers superior efficiency and cost-effectiveness for high-volume manufacturing, delivering consistent part quality and faster production cycles. The choice depends on production volume, design complexity, and budget constraints within the manufacturing process.

Connection

Additive manufacturing and molding intersect through their shared goal of creating precise, custom components efficiently, with additive manufacturing often used to produce molds or prototypes before large-scale molding production. This integration accelerates design validation and iteration while reducing costs associated with traditional mold fabrication. Leveraging 3D printing technology enables rapid tooling and complex geometries that are difficult to achieve with conventional molding methods.

Key Terms

Tooling

Molding utilizes custom tooling molds made from metals like steel or aluminum to shape materials through processes such as injection or compression molding, offering high-volume production efficiency and consistent part quality. Additive manufacturing employs digital CAD models and layer-by-layer material deposition, facilitating rapid tooling development with reduced lead times and lower upfront costs, ideal for prototyping and low-volume runs. Explore the intricacies of tooling advantages in molding and additive manufacturing to optimize your production strategy.

Layer-by-layer

Molding creates objects by shaping material within a defined cavity, producing parts in a single process without layering, while additive manufacturing builds components layer-by-layer, adding material successively to form complex geometries. The layer-by-layer technique in additive manufacturing enables intricate designs and customization that traditional molding cannot achieve efficiently. Discover more about how layer-based fabrication revolutionizes manufacturing versatility and precision.

Material deposition

Material deposition in molding typically involves shaping molten or pliable materials within molds to form precise components, whereas additive manufacturing builds objects layer by layer by depositing material directly based on digital models. Injection molding uses high pressure to inject melted polymers into molds, ensuring uniform material distribution, while additive manufacturing methods like fused deposition modeling (FDM) extrude thermoplastic filaments to create complex geometries with minimal waste. Explore the detailed differences in material deposition techniques to understand their impact on manufacturing efficiency and design flexibility.

Source and External Links

Molding (decorative) - Molding is a strip of material with various profiles used to cover transitions between surfaces or for decoration, traditionally made from wood, plaster, or stone, but also from plastics; common types include torus and trim moldings.

Wood Mouldings | Trim & Edge Moulding - This source offers a wide selection of traditional and classical wood moldings, including crown moldings, casings, chair rails, and various detailed profiles for decorative and functional use.

Hardwood Panel Moulding Trim Super Store - Premium hardwood panel moldings like crown, casings, baseboards, and chair rails are available in various wood species such as cherry, maple, and walnut, suitable to enhance design elements.

dowidth.com

dowidth.com