Digital twin technology creates real-time virtual replicas of physical manufacturing processes, enabling precise simulation and proactive maintenance to improve efficiency. Big data analytics processes vast volumes of manufacturing data to uncover patterns, optimize production, and predict equipment failures through advanced algorithms. Explore how integrating digital twins with big data analytics can revolutionize manufacturing performance and innovation.

Why it is important

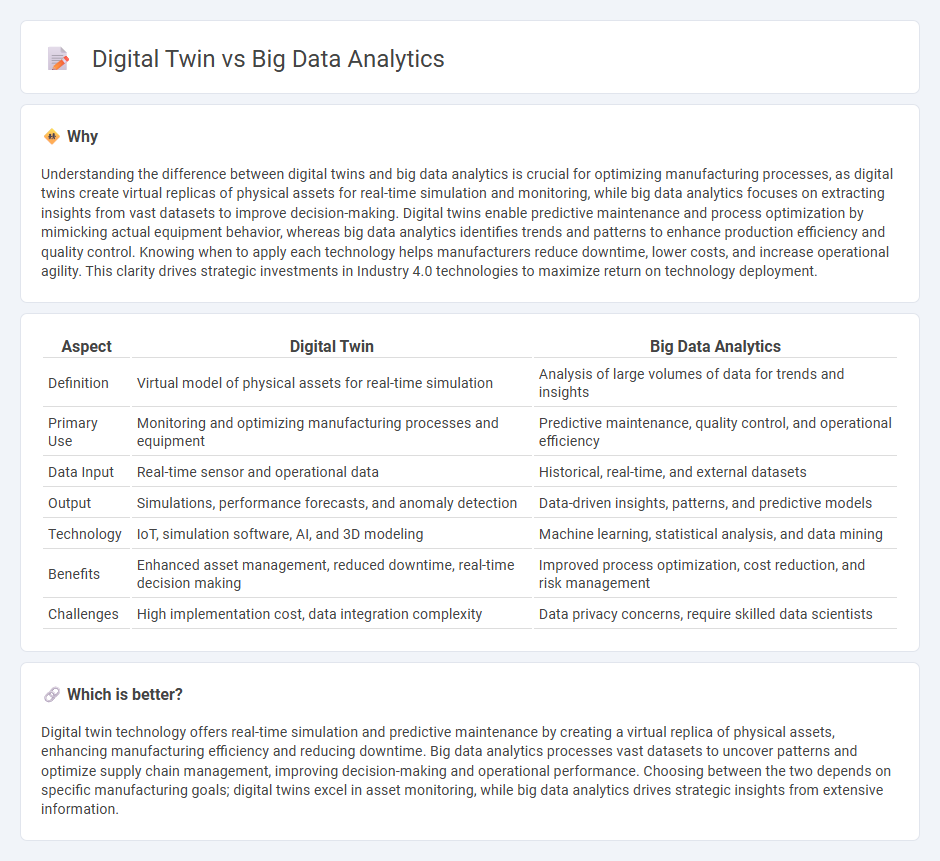

Understanding the difference between digital twins and big data analytics is crucial for optimizing manufacturing processes, as digital twins create virtual replicas of physical assets for real-time simulation and monitoring, while big data analytics focuses on extracting insights from vast datasets to improve decision-making. Digital twins enable predictive maintenance and process optimization by mimicking actual equipment behavior, whereas big data analytics identifies trends and patterns to enhance production efficiency and quality control. Knowing when to apply each technology helps manufacturers reduce downtime, lower costs, and increase operational agility. This clarity drives strategic investments in Industry 4.0 technologies to maximize return on technology deployment.

Comparison Table

| Aspect | Digital Twin | Big Data Analytics |

|---|---|---|

| Definition | Virtual model of physical assets for real-time simulation | Analysis of large volumes of data for trends and insights |

| Primary Use | Monitoring and optimizing manufacturing processes and equipment | Predictive maintenance, quality control, and operational efficiency |

| Data Input | Real-time sensor and operational data | Historical, real-time, and external datasets |

| Output | Simulations, performance forecasts, and anomaly detection | Data-driven insights, patterns, and predictive models |

| Technology | IoT, simulation software, AI, and 3D modeling | Machine learning, statistical analysis, and data mining |

| Benefits | Enhanced asset management, reduced downtime, real-time decision making | Improved process optimization, cost reduction, and risk management |

| Challenges | High implementation cost, data integration complexity | Data privacy concerns, require skilled data scientists |

Which is better?

Digital twin technology offers real-time simulation and predictive maintenance by creating a virtual replica of physical assets, enhancing manufacturing efficiency and reducing downtime. Big data analytics processes vast datasets to uncover patterns and optimize supply chain management, improving decision-making and operational performance. Choosing between the two depends on specific manufacturing goals; digital twins excel in asset monitoring, while big data analytics drives strategic insights from extensive information.

Connection

Digital twin technology leverages big data analytics by creating virtual replicas of physical manufacturing processes, enabling real-time monitoring and predictive maintenance. Big data analytics processes vast amounts of sensor and operational data collected from the digital twin to optimize production efficiency and reduce downtime. This integration helps manufacturers enhance decision-making and improve overall equipment effectiveness (OEE).

Key Terms

Data Integration

Big data analytics relies on aggregating and processing vast datasets from various sources to uncover patterns and insights, emphasizing seamless data integration across heterogeneous systems for real-time decision-making. Digital twin technology integrates real-time data streams with virtual models to simulate physical assets, requiring high-fidelity synchronization and continuous updates of sensor data for precise operational replication. Explore how advanced data integration strategies enhance the synergy between big data analytics and digital twins for optimized performance.

Real-time Monitoring

Big data analytics processes vast volumes of data to identify patterns and trends, enabling predictive insights primarily through historical and batch data analysis. Digital twins create dynamic virtual replicas of physical assets, offering real-time monitoring and simulation to optimize operations and detect anomalies instantly. Explore how integrating big data analytics with digital twins enhances precise, real-time decision-making for industrial applications.

Predictive Modeling

Big data analytics leverages vast datasets to identify patterns and trends, enabling predictive modeling by forecasting future outcomes based on historical data. Digital twins create real-time virtual replicas of physical assets or systems, using continuous sensor data to simulate and predict performance under varying conditions. Explore how integrating both approaches can enhance predictive accuracy and operational efficiency.

Source and External Links

What is Big Data Analytics? - Big data analytics involves the systematic processing and analysis of large, complex datasets to uncover trends, patterns, and insights that help organizations make data-driven decisions.

Big Data Analytics: What It Is & How It Works - Organizations collect, process, clean, and analyze massive datasets from diverse sources, using advanced techniques like data mining, predictive analytics, and deep learning to operationalize big data and extract actionable intelligence.

What is Big Data Analytics? - Big data analytics employs methods and tools to collect, organize, clean, and analyze high-volume, high-velocity data from various sources, leveraging AI, machine learning, and statistical analysis to predict outcomes and reveal behavioral patterns.

dowidth.com

dowidth.com