Biofabrication leverages biological materials and living cells to create complex, functional tissue structures, enhancing precision in regenerative medicine and personalized treatments. Laser sintering employs high-powered lasers to fuse powdered materials layer by layer, offering superior accuracy in producing durable, intricate industrial components. Explore the unique advantages and applications of both technologies in advancing manufacturing innovation.

Why it is important

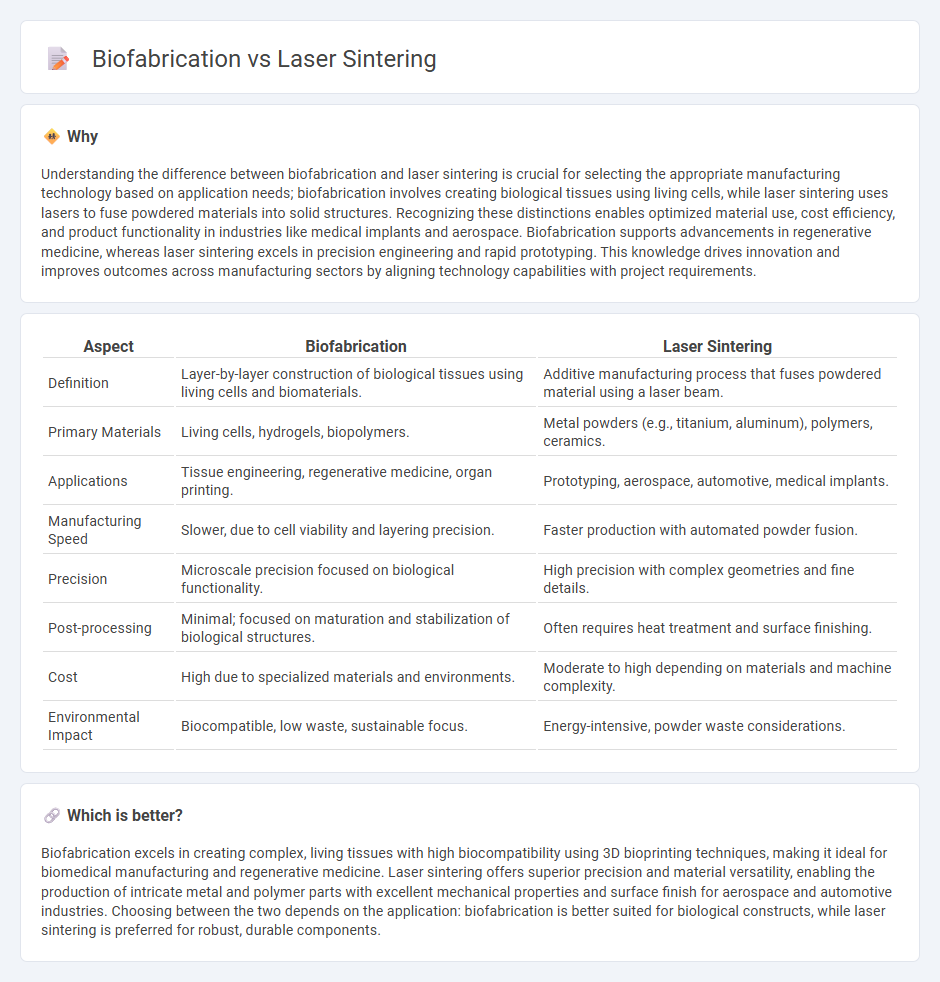

Understanding the difference between biofabrication and laser sintering is crucial for selecting the appropriate manufacturing technology based on application needs; biofabrication involves creating biological tissues using living cells, while laser sintering uses lasers to fuse powdered materials into solid structures. Recognizing these distinctions enables optimized material use, cost efficiency, and product functionality in industries like medical implants and aerospace. Biofabrication supports advancements in regenerative medicine, whereas laser sintering excels in precision engineering and rapid prototyping. This knowledge drives innovation and improves outcomes across manufacturing sectors by aligning technology capabilities with project requirements.

Comparison Table

| Aspect | Biofabrication | Laser Sintering |

|---|---|---|

| Definition | Layer-by-layer construction of biological tissues using living cells and biomaterials. | Additive manufacturing process that fuses powdered material using a laser beam. |

| Primary Materials | Living cells, hydrogels, biopolymers. | Metal powders (e.g., titanium, aluminum), polymers, ceramics. |

| Applications | Tissue engineering, regenerative medicine, organ printing. | Prototyping, aerospace, automotive, medical implants. |

| Manufacturing Speed | Slower, due to cell viability and layering precision. | Faster production with automated powder fusion. |

| Precision | Microscale precision focused on biological functionality. | High precision with complex geometries and fine details. |

| Post-processing | Minimal; focused on maturation and stabilization of biological structures. | Often requires heat treatment and surface finishing. |

| Cost | High due to specialized materials and environments. | Moderate to high depending on materials and machine complexity. |

| Environmental Impact | Biocompatible, low waste, sustainable focus. | Energy-intensive, powder waste considerations. |

Which is better?

Biofabrication excels in creating complex, living tissues with high biocompatibility using 3D bioprinting techniques, making it ideal for biomedical manufacturing and regenerative medicine. Laser sintering offers superior precision and material versatility, enabling the production of intricate metal and polymer parts with excellent mechanical properties and surface finish for aerospace and automotive industries. Choosing between the two depends on the application: biofabrication is better suited for biological constructs, while laser sintering is preferred for robust, durable components.

Connection

Biofabrication integrates living cells and biomaterials to create complex tissue structures, while laser sintering uses focused laser energy to fuse powdered materials layer by layer into precise shapes. Both technologies intersect in advanced manufacturing by enabling the production of customized, high-resolution biomedical implants and scaffolds with intricate geometries. This synergy enhances regenerative medicine by combining cellular bioengineering with additive manufacturing's accuracy and material versatility.

Key Terms

Powder Bed Fusion

Laser sintering, a key technique in Powder Bed Fusion (PBF), uses a laser to selectively fuse powdered materials layer by layer, offering high precision and complex geometries ideal for metal and polymer parts. Biofabrication leverages similar additive manufacturing principles but incorporates living cells and biomaterials to create tissue-like structures, emphasizing biocompatibility and functionality. Explore further to understand the nuanced advantages and applications of Powder Bed Fusion in both industrial manufacturing and biomedical engineering.

Biomaterials

Laser sintering utilizes high-powered lasers to fuse powdered biomaterials, enabling the creation of complex, patient-specific shapes with high precision and mechanical strength. Biofabrication encompasses a range of additive manufacturing techniques, including bioprinting, that incorporate living cells and biomolecules to engineer functional tissue constructs with enhanced biological integration. Explore the latest advancements in biomaterial compatibility and applications to understand which method best suits your biomedical needs.

Tissue Engineering

Laser sintering offers precise layer-by-layer scaffolding, enabling the creation of complex 3D structures with controlled porosity and mechanical strength ideal for tissue engineering applications. Biofabrication incorporates living cells and biomaterials in additive manufacturing, promoting biomimetic tissue constructs that support cell viability and functionality. Explore the latest advancements in laser sintering and biofabrication to understand their transformative impact on regenerative medicine.

Source and External Links

Selective laser sintering - Wikipedia - Selective laser sintering (SLS) is an additive manufacturing technique that uses a laser to sinter powdered material, enabling the creation of complex geometries with minimal added manufacturing effort, widely used for prototyping and limited-run production in industries such as automotive, aerospace, and medical.

The Advantages and Disadvantages of Selective Laser Sintering - SLS is a reliable, precise, and fast method for producing prototypes and small batches by sintering layers of polymer powder with a laser, though it may not be ideal for all projects due to material and process limitations.

Direct Metal Laser Sintering: A Digitised Metal Casting Technology - Direct Metal Laser Sintering (DMLS) builds complex metal parts layer by layer directly from 3D CAD data using a high-power laser to fuse powdered metal, resulting in strong, precise components without traditional machining.

dowidth.com

dowidth.com