Additive manufacturing builds objects layer by layer using materials such as plastics, metals, or composites, enabling complex geometries and minimal waste. Subtractive manufacturing removes material through cutting, drilling, or milling from a solid block, offering high precision and smooth surface finishes for traditional manufacturing needs. Explore the benefits and applications of both techniques to determine the best fit for your production goals.

Why it is important

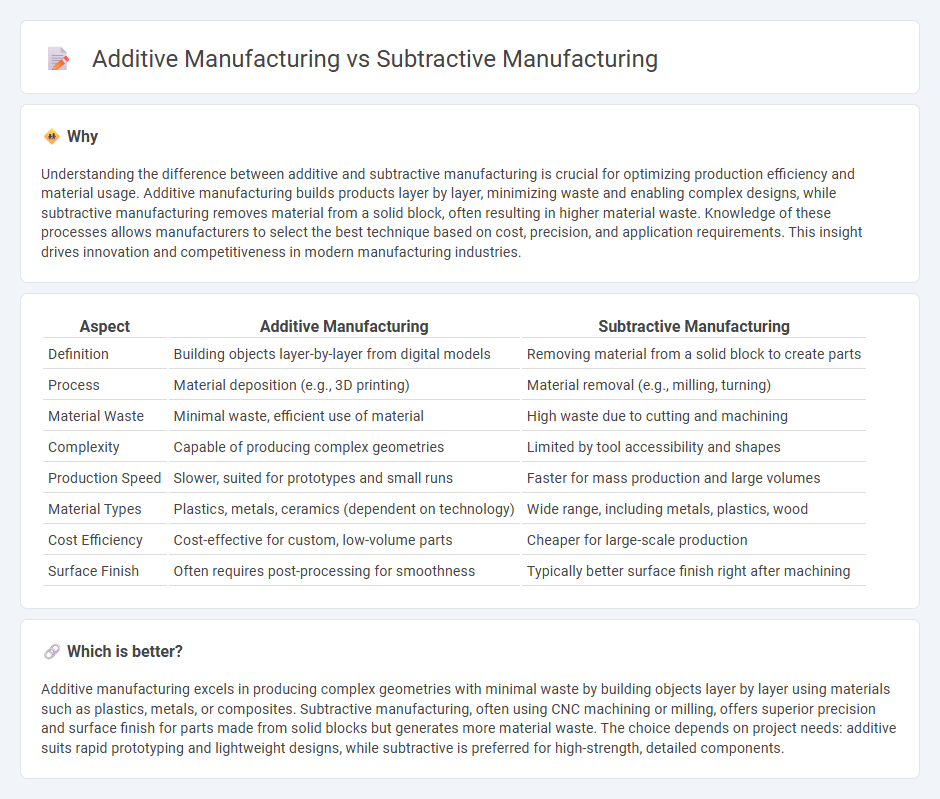

Understanding the difference between additive and subtractive manufacturing is crucial for optimizing production efficiency and material usage. Additive manufacturing builds products layer by layer, minimizing waste and enabling complex designs, while subtractive manufacturing removes material from a solid block, often resulting in higher material waste. Knowledge of these processes allows manufacturers to select the best technique based on cost, precision, and application requirements. This insight drives innovation and competitiveness in modern manufacturing industries.

Comparison Table

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Definition | Building objects layer-by-layer from digital models | Removing material from a solid block to create parts |

| Process | Material deposition (e.g., 3D printing) | Material removal (e.g., milling, turning) |

| Material Waste | Minimal waste, efficient use of material | High waste due to cutting and machining |

| Complexity | Capable of producing complex geometries | Limited by tool accessibility and shapes |

| Production Speed | Slower, suited for prototypes and small runs | Faster for mass production and large volumes |

| Material Types | Plastics, metals, ceramics (dependent on technology) | Wide range, including metals, plastics, wood |

| Cost Efficiency | Cost-effective for custom, low-volume parts | Cheaper for large-scale production |

| Surface Finish | Often requires post-processing for smoothness | Typically better surface finish right after machining |

Which is better?

Additive manufacturing excels in producing complex geometries with minimal waste by building objects layer by layer using materials such as plastics, metals, or composites. Subtractive manufacturing, often using CNC machining or milling, offers superior precision and surface finish for parts made from solid blocks but generates more material waste. The choice depends on project needs: additive suits rapid prototyping and lightweight designs, while subtractive is preferred for high-strength, detailed components.

Connection

Additive manufacturing and subtractive manufacturing are connected through their complementary roles in modern production processes, where additive techniques build parts layer by layer while subtractive methods refine or remove material for final precision. Both approaches leverage digital design files, enabling seamless integration in hybrid manufacturing systems that optimize efficiency, reduce waste, and enhance customization. Combining these technologies allows manufacturers to exploit the strengths of each method, resulting in improved product complexity and reduced lead times.

Key Terms

Material Removal (Subtractive)

Subtractive manufacturing relies on material removal techniques such as milling, turning, and drilling to shape a workpiece from a solid block, offering high precision and repeatability for metals, plastics, and composites. This process generates waste material, requiring efficient scrap management and often resulting in longer production times compared to additive manufacturing. Explore the key differences in efficiency, cost, and applications between subtractive and additive manufacturing methods to optimize your production strategy.

Layer-by-Layer Deposition (Additive)

Layer-by-layer deposition in additive manufacturing builds objects by successively adding material, contrasting with subtractive manufacturing that removes material from a solid block. This process enables intricate geometries, complex internal structures, and material efficiency not achievable through traditional subtractive methods. Explore the benefits and applications of layer-by-layer deposition to understand its impact on modern manufacturing.

Source and External Links

Additive vs. Subtractive Manufacturing - Formlabs - Subtractive manufacturing creates parts by *removing material* from solid blocks using processes like cutting, boring, drilling, and grinding, often driven by CNC machines for precision and complex geometries.

Subtractive Manufacturing vs. Additive Manufacturing | Xometry Pro - In subtractive manufacturing, objects are made by progressively cutting away material from a solid block using CNC machining, laser cutting, waterjet cutting, or EDM to produce precise and smooth finished parts.

Subtractive Manufacturing: Past, Present, and Future - Subtractive manufacturing refers to machining processes that *cut, shape, or finish* materials to desired shapes, and modern hybrid manufacturing combines this with additive techniques for enhanced part creation and finishing.

dowidth.com

dowidth.com