Microfactories focus on compact, highly automated production units designed for localized, small-batch manufacturing, optimizing speed and customization. Flexible manufacturing systems (FMS) utilize interconnected machines and robotics to efficiently manage variable product types and volumes within larger-scale industrial environments. Discover how these advanced manufacturing approaches drive innovation and operational efficiency in modern industries.

Why it is important

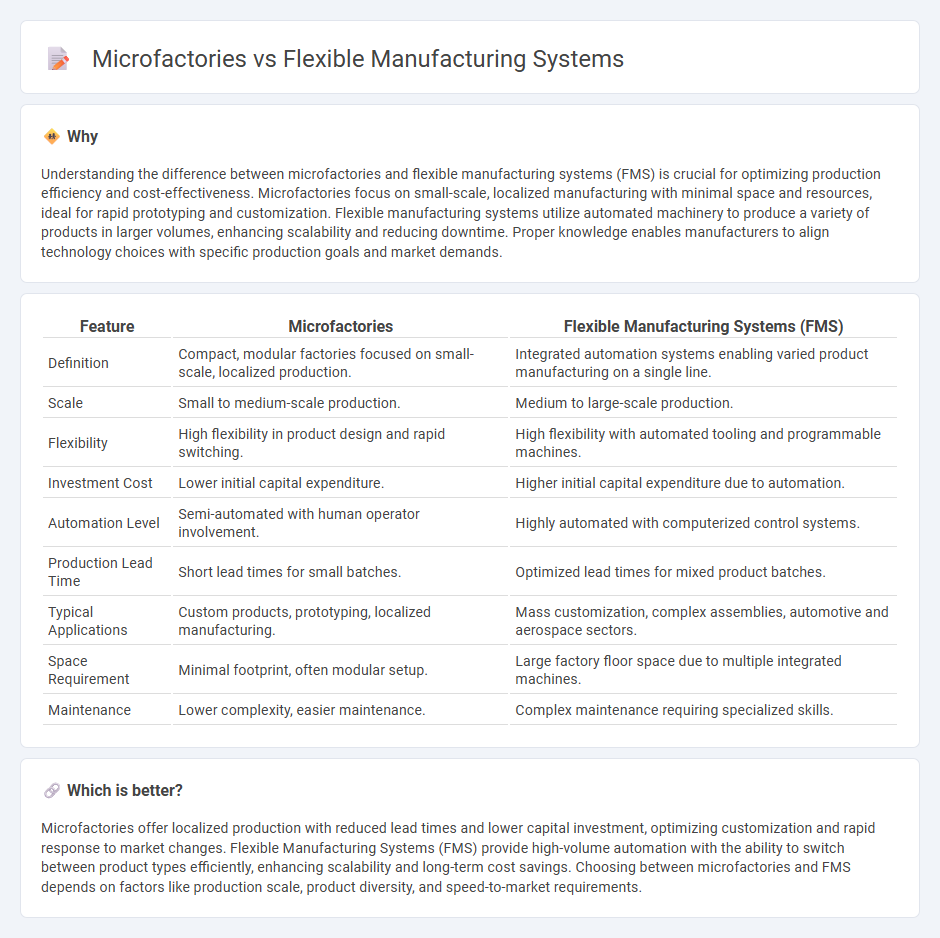

Understanding the difference between microfactories and flexible manufacturing systems (FMS) is crucial for optimizing production efficiency and cost-effectiveness. Microfactories focus on small-scale, localized manufacturing with minimal space and resources, ideal for rapid prototyping and customization. Flexible manufacturing systems utilize automated machinery to produce a variety of products in larger volumes, enhancing scalability and reducing downtime. Proper knowledge enables manufacturers to align technology choices with specific production goals and market demands.

Comparison Table

| Feature | Microfactories | Flexible Manufacturing Systems (FMS) |

|---|---|---|

| Definition | Compact, modular factories focused on small-scale, localized production. | Integrated automation systems enabling varied product manufacturing on a single line. |

| Scale | Small to medium-scale production. | Medium to large-scale production. |

| Flexibility | High flexibility in product design and rapid switching. | High flexibility with automated tooling and programmable machines. |

| Investment Cost | Lower initial capital expenditure. | Higher initial capital expenditure due to automation. |

| Automation Level | Semi-automated with human operator involvement. | Highly automated with computerized control systems. |

| Production Lead Time | Short lead times for small batches. | Optimized lead times for mixed product batches. |

| Typical Applications | Custom products, prototyping, localized manufacturing. | Mass customization, complex assemblies, automotive and aerospace sectors. |

| Space Requirement | Minimal footprint, often modular setup. | Large factory floor space due to multiple integrated machines. |

| Maintenance | Lower complexity, easier maintenance. | Complex maintenance requiring specialized skills. |

Which is better?

Microfactories offer localized production with reduced lead times and lower capital investment, optimizing customization and rapid response to market changes. Flexible Manufacturing Systems (FMS) provide high-volume automation with the ability to switch between product types efficiently, enhancing scalability and long-term cost savings. Choosing between microfactories and FMS depends on factors like production scale, product diversity, and speed-to-market requirements.

Connection

Microfactories and Flexible Manufacturing Systems (FMS) both enhance production efficiency by enabling rapid reconfiguration and customization of manufacturing processes. Microfactories utilize modular equipment and compact layouts, while FMS integrates automated machines and computer control to switch between tasks seamlessly. Together, they support agile manufacturing strategies that reduce lead times and improve responsiveness to market demands.

Key Terms

Automation

Flexible manufacturing systems (FMS) integrate advanced robotics, computer-controlled machines, and automated logistics to enable rapid adjustments in production processes, enhancing efficiency and customization. Microfactories prioritize compact, modular automation with a focus on localized production, energy efficiency, and real-time adaptability through interconnected digital systems. Explore how automation drives innovation and operational agility in both flexible manufacturing systems and microfactories.

Scalability

Flexible manufacturing systems offer high scalability through modular machinery capable of producing varied products with minimal downtime, adapting efficiently to changing production volumes. Microfactories emphasize scalability by leveraging compact, autonomous units optimized for localized, small-batch manufacturing with rapid reconfiguration based on demand. Explore the advantages of each approach to determine which scalability model best suits your production goals.

Customization

Flexible manufacturing systems (FMS) enable mass customization by integrating automated machinery with computer-controlled processes, allowing rapid adaptation to varied product designs while maintaining efficiency. Microfactories emphasize decentralized production with compact layouts optimized for small batch sizes and localized customization, enhancing responsiveness to specific customer preferences. Explore the distinct customization advantages of FMS and microfactories to determine the best fit for your manufacturing needs.

Source and External Links

Flexible Manufacturing System - A flexible manufacturing system is a computer-controlled production setup designed to adapt to changes, offering advantages like reduced manufacturing costs and improved efficiency.

How Flexible Manufacturing System (FMS) is Changing Production - Flexible manufacturing systems are integrated, computer-controlled configurations that combine automation efficiency with adaptability to changes in real-time.

Flexible Manufacturing Systems (FMS) - Flexible manufacturing systems are adaptable production setups that adjust to product details, batch sizes, and sequence changes using routing and machine flexibility.

dowidth.com

dowidth.com