Lattice structure design offers customizable strength-to-weight ratios by utilizing periodic templates tailored for precise load distribution in manufacturing applications. Gyroid structure design enhances material efficiency with its continuous, triply periodic minimal surface, providing superior isotropic mechanical properties and high surface area for heat exchange or filtration. Explore the benefits and applications of these innovative designs to optimize your manufacturing processes.

Why it is important

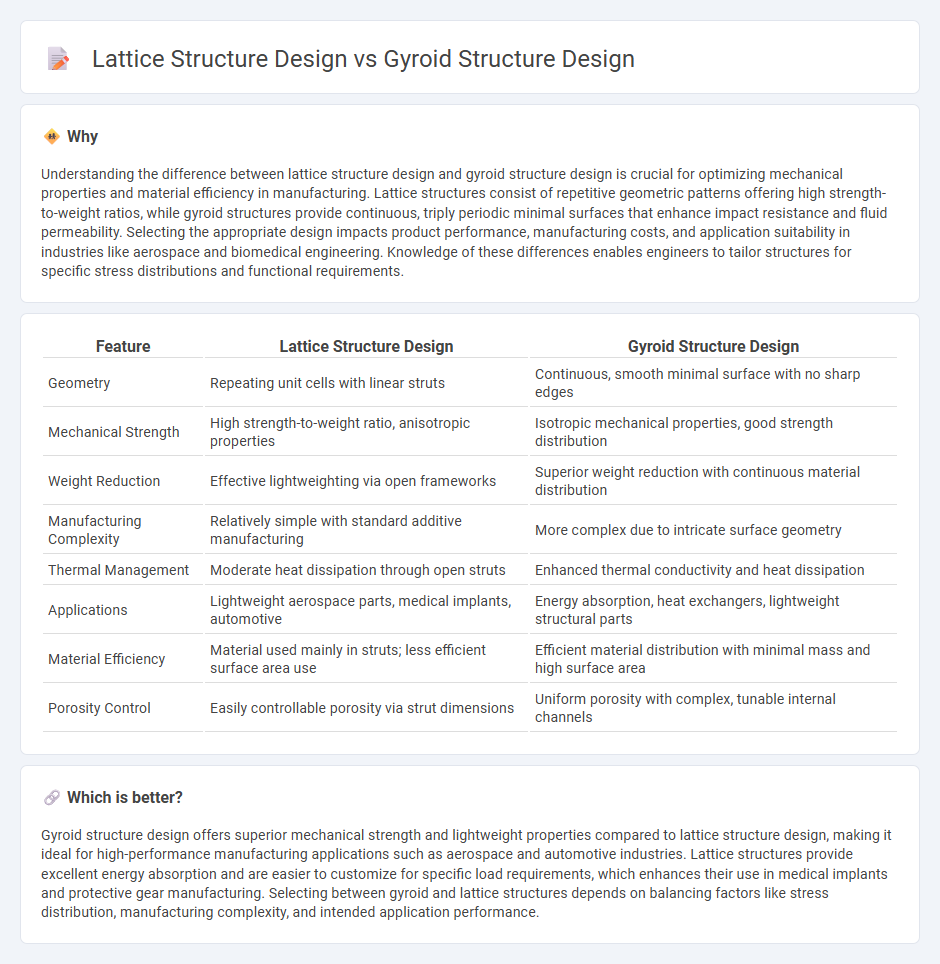

Understanding the difference between lattice structure design and gyroid structure design is crucial for optimizing mechanical properties and material efficiency in manufacturing. Lattice structures consist of repetitive geometric patterns offering high strength-to-weight ratios, while gyroid structures provide continuous, triply periodic minimal surfaces that enhance impact resistance and fluid permeability. Selecting the appropriate design impacts product performance, manufacturing costs, and application suitability in industries like aerospace and biomedical engineering. Knowledge of these differences enables engineers to tailor structures for specific stress distributions and functional requirements.

Comparison Table

| Feature | Lattice Structure Design | Gyroid Structure Design |

|---|---|---|

| Geometry | Repeating unit cells with linear struts | Continuous, smooth minimal surface with no sharp edges |

| Mechanical Strength | High strength-to-weight ratio, anisotropic properties | Isotropic mechanical properties, good strength distribution |

| Weight Reduction | Effective lightweighting via open frameworks | Superior weight reduction with continuous material distribution |

| Manufacturing Complexity | Relatively simple with standard additive manufacturing | More complex due to intricate surface geometry |

| Thermal Management | Moderate heat dissipation through open struts | Enhanced thermal conductivity and heat dissipation |

| Applications | Lightweight aerospace parts, medical implants, automotive | Energy absorption, heat exchangers, lightweight structural parts |

| Material Efficiency | Material used mainly in struts; less efficient surface area use | Efficient material distribution with minimal mass and high surface area |

| Porosity Control | Easily controllable porosity via strut dimensions | Uniform porosity with complex, tunable internal channels |

Which is better?

Gyroid structure design offers superior mechanical strength and lightweight properties compared to lattice structure design, making it ideal for high-performance manufacturing applications such as aerospace and automotive industries. Lattice structures provide excellent energy absorption and are easier to customize for specific load requirements, which enhances their use in medical implants and protective gear manufacturing. Selecting between gyroid and lattice structures depends on balancing factors like stress distribution, manufacturing complexity, and intended application performance.

Connection

Lattice structure design and Gyroid structure design intersect through their use of complex, three-dimensional geometries optimized for lightweight strength and material efficiency in manufacturing. Both designs leverage periodic minimal surfaces to enhance load distribution and reduce weight in components produced via additive manufacturing techniques. This connection allows for improved mechanical properties and energy absorption in industries such as aerospace, automotive, and biomedical engineering.

Key Terms

Topology Optimization

Gyroid structure design offers continuous, triply periodic minimal surfaces that optimize stiffness-to-weight ratios and enhance mechanical performance compared to traditional lattice structures featuring repeating unit cells. Topology optimization applied to gyroid geometries enables precise control over material distribution, resulting in lightweight components with superior load-bearing capabilities and improved energy absorption characteristics. Explore further to understand how integrating topology optimization with gyroid structures revolutionizes advanced material engineering.

Additive Manufacturing

Gyroid structure design offers continuous, triply periodic minimal surfaces that enhance strength-to-weight ratios and optimize energy absorption in Additive Manufacturing compared to traditional lattice structures composed of discrete struts or nodes. The gyroid's complex geometry minimizes stress concentrations and improves thermal and fluid flow properties, making it ideal for lightweight aerospace components and biomedical implants. Explore further to understand how gyroid geometries revolutionize material performance and manufacturing efficiency.

Mechanical Performance

Gyroid structures offer superior mechanical properties such as enhanced strength-to-weight ratio and improved energy absorption compared to traditional lattice structures due to their continuous, triply periodic minimal surface geometry. This unique geometry facilitates uniform stress distribution and excellent fatigue resistance, making gyroid designs ideal for lightweight, high-performance applications in aerospace and biomedical implants. Explore detailed comparisons and performance metrics to understand how gyroid and lattice structures influence mechanical durability and application suitability.

Source and External Links

3D Printing Gyroid Infill: Strength, Efficiency, Precision - BigRep - A gyroid structure is a triply periodic minimal surface (TPMS) with two intertwined channel networks that offers strength, lightweight design, and precision; it is widely used in 3D printing as an infill pattern for enhanced mechanical performance and material efficiency.

Gyroid - Wikipedia - The gyroid is a mathematically unique, embedded triply periodic minimal surface discovered by Alan Schoen in 1970, characterized by no straight lines or planar symmetries and separating space into two congruent labyrinths with complex channel networks.

Computational Design and Characterisation of Gyroid Structures ... - This research discusses the computational design of gyroid structures with variable porosity gradients using input parameters like unit cell size and gradient functions to tailor mechanical properties in 3D-printed gyroids.

dowidth.com

dowidth.com