Biofabrication integrates living cells with biomaterials to create tissue-like structures, enabling regenerative medicine and personalized implants. Stereolithography uses ultraviolet light to cure photopolymer resins layer-by-layer, offering high precision in producing complex prototypes and components for various industries. Explore more about how these advanced manufacturing techniques are revolutionizing product development and healthcare solutions.

Why it is important

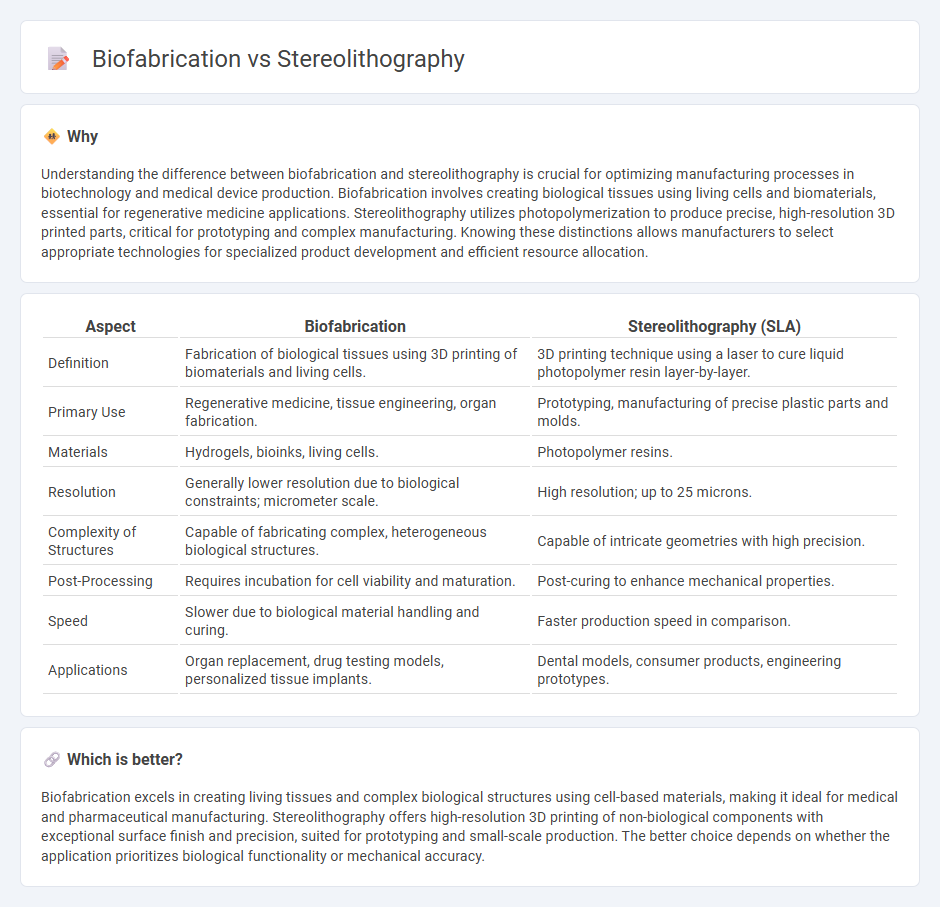

Understanding the difference between biofabrication and stereolithography is crucial for optimizing manufacturing processes in biotechnology and medical device production. Biofabrication involves creating biological tissues using living cells and biomaterials, essential for regenerative medicine applications. Stereolithography utilizes photopolymerization to produce precise, high-resolution 3D printed parts, critical for prototyping and complex manufacturing. Knowing these distinctions allows manufacturers to select appropriate technologies for specialized product development and efficient resource allocation.

Comparison Table

| Aspect | Biofabrication | Stereolithography (SLA) |

|---|---|---|

| Definition | Fabrication of biological tissues using 3D printing of biomaterials and living cells. | 3D printing technique using a laser to cure liquid photopolymer resin layer-by-layer. |

| Primary Use | Regenerative medicine, tissue engineering, organ fabrication. | Prototyping, manufacturing of precise plastic parts and molds. |

| Materials | Hydrogels, bioinks, living cells. | Photopolymer resins. |

| Resolution | Generally lower resolution due to biological constraints; micrometer scale. | High resolution; up to 25 microns. |

| Complexity of Structures | Capable of fabricating complex, heterogeneous biological structures. | Capable of intricate geometries with high precision. |

| Post-Processing | Requires incubation for cell viability and maturation. | Post-curing to enhance mechanical properties. |

| Speed | Slower due to biological material handling and curing. | Faster production speed in comparison. |

| Applications | Organ replacement, drug testing models, personalized tissue implants. | Dental models, consumer products, engineering prototypes. |

Which is better?

Biofabrication excels in creating living tissues and complex biological structures using cell-based materials, making it ideal for medical and pharmaceutical manufacturing. Stereolithography offers high-resolution 3D printing of non-biological components with exceptional surface finish and precision, suited for prototyping and small-scale production. The better choice depends on whether the application prioritizes biological functionality or mechanical accuracy.

Connection

Biofabrication leverages stereolithography (SLA) as a precise 3D printing technique to construct complex biological structures layer-by-layer using photopolymerizable bioinks. Stereolithography enables high-resolution fabrication of tissue scaffolds and organ models by curing photosensitive materials with targeted laser light, essential for replicating intricate cellular architectures. The integration of stereolithography in biofabrication enhances the customization and functionality of biomedical components, advancing regenerative medicine and tissue engineering.

Key Terms

Photopolymerization

Stereolithography (SLA) utilizes photopolymerization to create precise 3D structures by curing liquid resin with a UV laser, widely applied in rapid prototyping and medical device manufacturing. Biofabrication leverages photopolymerization to build biological constructs, enabling the formation of complex tissue scaffolds with high spatial resolution and biocompatibility. Explore the nuances of photopolymerization in both fields to understand their distinct applications and technological innovations.

Biomaterials

Stereolithography employs photopolymerizable resins to create high-resolution, biocompatible scaffolds crucial for tissue engineering. Biofabrication integrates various biomaterials such as hydrogels, decellularized matrices, and cell-laden bioinks to replicate complex tissue architecture and functionality. Explore the latest advancements in biomaterials to understand their impact on stereolithography and biofabrication technologies.

Tissue engineering

Stereolithography offers high-resolution 3D printing capabilities that enable precise scaffold fabrication crucial for tissue engineering applications, allowing for customized tissue constructs with intricate architectures. Biofabrication integrates living cells and biomaterials, fostering the development of biocompatible, functional tissues that can replicate native tissue properties and enhance regenerative medicine outcomes. Explore the latest advancements and comparative analyses to understand how these technologies are revolutionizing tissue engineering.

Source and External Links

Stereolithography - Wikipedia - Stereolithography (SLA) is a 3D printing technology that creates objects by curing liquid photopolymer resin with UV light layer by layer, enabling the production of highly detailed parts for prototyping and small-batch manufacturing.

Stereolithography (SLA) 3D Printing Service - Xometry - SLA uses ultraviolet light to solidify liquid resin in a vat, building high-resolution, accurate parts with fine details and smooth surfaces, used for rapid prototyping, tooling, and end-use components in industries such as automotive and medical devices.

Guide to Stereolithography (SLA) 3D Printing - Formlabs - SLA offers fast print speeds, exceptional resolution, and smooth finishes, with a wide range of advanced resins available, making it suitable for applications from professional prototyping to production-grade end-use parts.

dowidth.com

dowidth.com