Mass customization delivers personalized products at near mass production efficiency by leveraging flexible manufacturing systems and advanced digital technologies. Batch production focuses on producing goods in specific quantities, optimizing cost and consistency while limiting variation. Explore how these manufacturing strategies shape product development and operational agility.

Why it is important

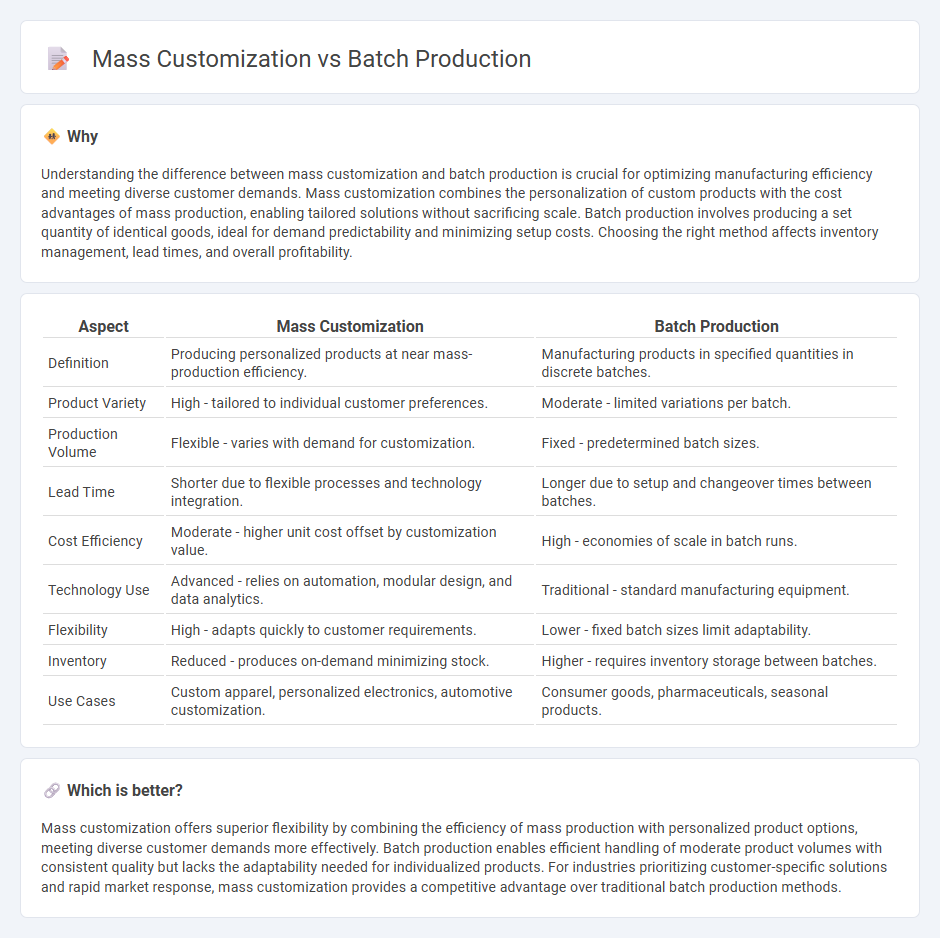

Understanding the difference between mass customization and batch production is crucial for optimizing manufacturing efficiency and meeting diverse customer demands. Mass customization combines the personalization of custom products with the cost advantages of mass production, enabling tailored solutions without sacrificing scale. Batch production involves producing a set quantity of identical goods, ideal for demand predictability and minimizing setup costs. Choosing the right method affects inventory management, lead times, and overall profitability.

Comparison Table

| Aspect | Mass Customization | Batch Production |

|---|---|---|

| Definition | Producing personalized products at near mass-production efficiency. | Manufacturing products in specified quantities in discrete batches. |

| Product Variety | High - tailored to individual customer preferences. | Moderate - limited variations per batch. |

| Production Volume | Flexible - varies with demand for customization. | Fixed - predetermined batch sizes. |

| Lead Time | Shorter due to flexible processes and technology integration. | Longer due to setup and changeover times between batches. |

| Cost Efficiency | Moderate - higher unit cost offset by customization value. | High - economies of scale in batch runs. |

| Technology Use | Advanced - relies on automation, modular design, and data analytics. | Traditional - standard manufacturing equipment. |

| Flexibility | High - adapts quickly to customer requirements. | Lower - fixed batch sizes limit adaptability. |

| Inventory | Reduced - produces on-demand minimizing stock. | Higher - requires inventory storage between batches. |

| Use Cases | Custom apparel, personalized electronics, automotive customization. | Consumer goods, pharmaceuticals, seasonal products. |

Which is better?

Mass customization offers superior flexibility by combining the efficiency of mass production with personalized product options, meeting diverse customer demands more effectively. Batch production enables efficient handling of moderate product volumes with consistent quality but lacks the adaptability needed for individualized products. For industries prioritizing customer-specific solutions and rapid market response, mass customization provides a competitive advantage over traditional batch production methods.

Connection

Mass customization and batch production both focus on producing goods in specific quantities tailored to customer needs while maintaining efficiency. Batch production allows manufacturers to create groups of products with variations, facilitating customization without the high costs of fully individualized manufacturing. This connection enables companies to respond quickly to market demands by balancing the flexibility of customization with the economies of scale inherent in batch processes.

Key Terms

Flexibility

Batch production offers moderate flexibility by manufacturing products in groups to accommodate small variations, enabling adjustments between batches but limiting real-time customization. Mass customization combines the efficiency of mass production with individual product modifications through advanced technologies like modular design and digital manufacturing, significantly enhancing flexibility to meet diverse customer preferences. Explore how these production strategies balance efficiency and adaptability to optimize your manufacturing process.

Volume

Batch production typically handles moderate volumes through the repeated manufacturing of product groups, balancing flexibility and efficiency. Mass customization merges high-volume production methods with personalized product variations to meet individual customer preferences at scale. Explore how volume considerations impact manufacturing strategies and business outcomes in greater detail.

Product Variety

Batch production offers moderate product variety by producing goods in specific quantities, allowing customization between batches but limited within each run. Mass customization combines the efficiency of mass production with the personalization of custom-made products, enabling a high variety of tailored options while maintaining cost-efficiency. Explore further to understand how product variety impacts manufacturing strategies and customer satisfaction.

Source and External Links

What is batch production in manufacturing? - Batch production is a method of producing a group of identical products simultaneously, allowing flexibility for different batches and quality checks at each production stage, making it suitable for small to medium-sized manufacturers.

Batch Production - Benefits, Examples, and Tips - Batch production involves producing sets of identical products together through production stages, offering flexibility, quality control, and cost advantages while facing challenges like high work-in-progress inventory and potential idle time.

Batch Production: Examples, Advantages and Disadvantages - Batch production creates groups of identical products going through manufacturing stages simultaneously, with quality checks in each phase and requiring careful scheduling to avoid delays, providing flexibility not found in other production methods.

dowidth.com

dowidth.com