Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing operations, enhance efficiency, and reduce human intervention. Predictive maintenance leverages data analytics and IoT sensors to monitor equipment health in real-time, anticipating failures before they occur to minimize downtime and maintenance costs. Discover how combining hyperautomation with predictive maintenance can revolutionize manufacturing processes and drive operational excellence.

Why it is important

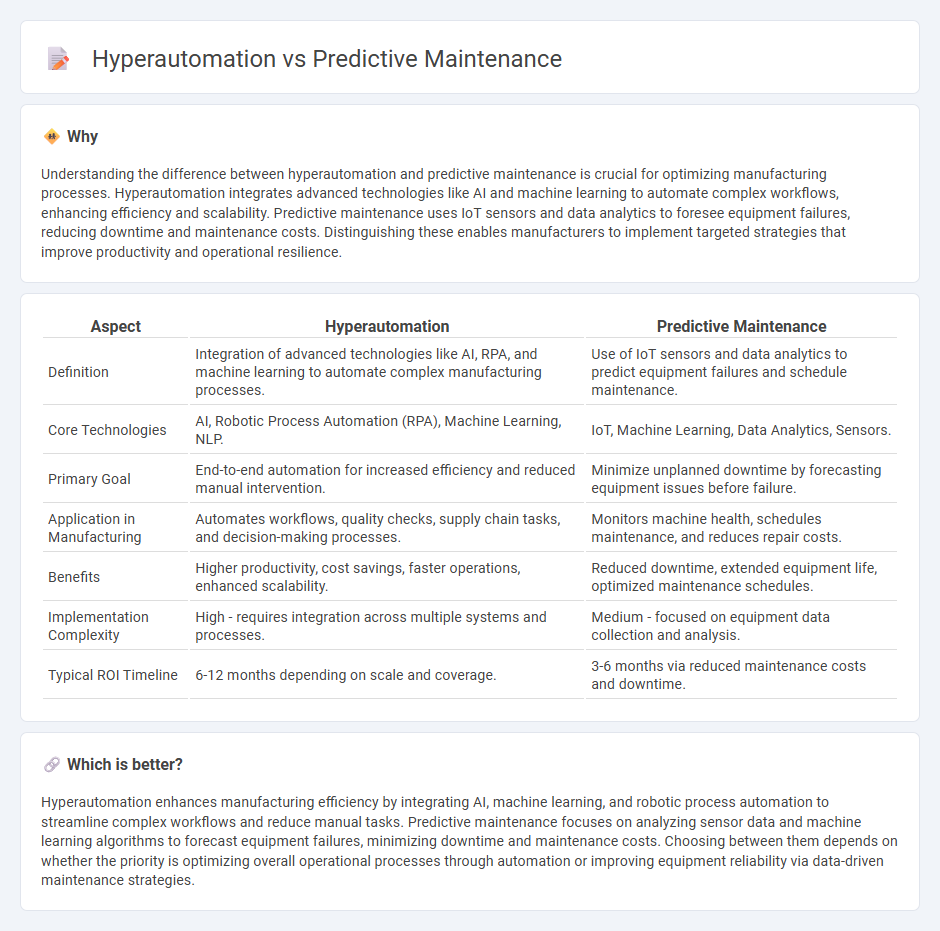

Understanding the difference between hyperautomation and predictive maintenance is crucial for optimizing manufacturing processes. Hyperautomation integrates advanced technologies like AI and machine learning to automate complex workflows, enhancing efficiency and scalability. Predictive maintenance uses IoT sensors and data analytics to foresee equipment failures, reducing downtime and maintenance costs. Distinguishing these enables manufacturers to implement targeted strategies that improve productivity and operational resilience.

Comparison Table

| Aspect | Hyperautomation | Predictive Maintenance |

|---|---|---|

| Definition | Integration of advanced technologies like AI, RPA, and machine learning to automate complex manufacturing processes. | Use of IoT sensors and data analytics to predict equipment failures and schedule maintenance. |

| Core Technologies | AI, Robotic Process Automation (RPA), Machine Learning, NLP. | IoT, Machine Learning, Data Analytics, Sensors. |

| Primary Goal | End-to-end automation for increased efficiency and reduced manual intervention. | Minimize unplanned downtime by forecasting equipment issues before failure. |

| Application in Manufacturing | Automates workflows, quality checks, supply chain tasks, and decision-making processes. | Monitors machine health, schedules maintenance, and reduces repair costs. |

| Benefits | Higher productivity, cost savings, faster operations, enhanced scalability. | Reduced downtime, extended equipment life, optimized maintenance schedules. |

| Implementation Complexity | High - requires integration across multiple systems and processes. | Medium - focused on equipment data collection and analysis. |

| Typical ROI Timeline | 6-12 months depending on scale and coverage. | 3-6 months via reduced maintenance costs and downtime. |

Which is better?

Hyperautomation enhances manufacturing efficiency by integrating AI, machine learning, and robotic process automation to streamline complex workflows and reduce manual tasks. Predictive maintenance focuses on analyzing sensor data and machine learning algorithms to forecast equipment failures, minimizing downtime and maintenance costs. Choosing between them depends on whether the priority is optimizing overall operational processes through automation or improving equipment reliability via data-driven maintenance strategies.

Connection

Hyperautomation leverages advanced technologies such as AI, machine learning, and robotic process automation to streamline manufacturing operations and integrate predictive maintenance seamlessly. Predictive maintenance utilizes real-time data analytics and IoT sensors to forecast equipment failures, enabling proactive repairs and minimizing downtime. The combination of hyperautomation and predictive maintenance enhances overall operational efficiency, reduces costs, and extends machinery lifespan by automating data-driven decision-making processes.

Key Terms

**Predictive Maintenance:**

Predictive maintenance leverages IoT sensors and machine learning algorithms to anticipate equipment failures, reducing unplanned downtime and maintenance costs by up to 30%. It continuously analyzes real-time data from machinery to optimize maintenance schedules, enhancing asset lifespan and operational efficiency. Explore how predictive maintenance transforms industrial operations with data-driven insights.

Condition Monitoring

Predictive maintenance leverages condition monitoring technologies such as vibration analysis, thermal imaging, and IoT sensors to anticipate equipment failures before they occur, reducing downtime and maintenance costs. Hyperautomation integrates advanced AI, machine learning, and robotic process automation, enhancing condition monitoring by automating data collection, analysis, and decision-making workflows for real-time operational efficiency. Explore how combining predictive maintenance with hyperautomation optimizes asset management and drives industry 4.0 innovation.

Failure Prediction

Predictive maintenance leverages machine learning algorithms and sensor data to anticipate equipment failures, enhancing operational efficiency and reducing downtime. Hyperautomation integrates advanced technologies like AI, RPA, and IoT to automate complex workflows, including failure prediction, driving comprehensive asset management. Explore how combining these approaches can revolutionize failure prediction in industrial environments.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses real-time sensor data and machine learning to forecast equipment failures and schedule maintenance only when needed, optimizing performance and reducing costs.

Predictive maintenance - Wikipedia - Predictive maintenance monitors the condition of in-service equipment to estimate exactly when maintenance should be performed, replacing scheduled or reactive approaches with data-driven, condition-based maintenance that can improve uptime and safety.

Predictive Maintenance: An Easy Guide | SafetyCulture - Predictive maintenance involves collecting real-time equipment data via IoT sensors, analyzing it with machine learning algorithms, and using those insights to schedule maintenance just before predicted failures, maximizing operational efficiency.

dowidth.com

dowidth.com