Industrial metaverse integrates virtual reality and IoT to create immersive, interactive environments for real-time simulation and collaboration in manufacturing processes. Cloud manufacturing centralizes resources and data on cloud platforms, enabling scalable, on-demand access to production capabilities and analytics. Explore the distinctive advantages and applications of industrial metaverse versus cloud manufacturing to enhance your manufacturing strategy.

Why it is important

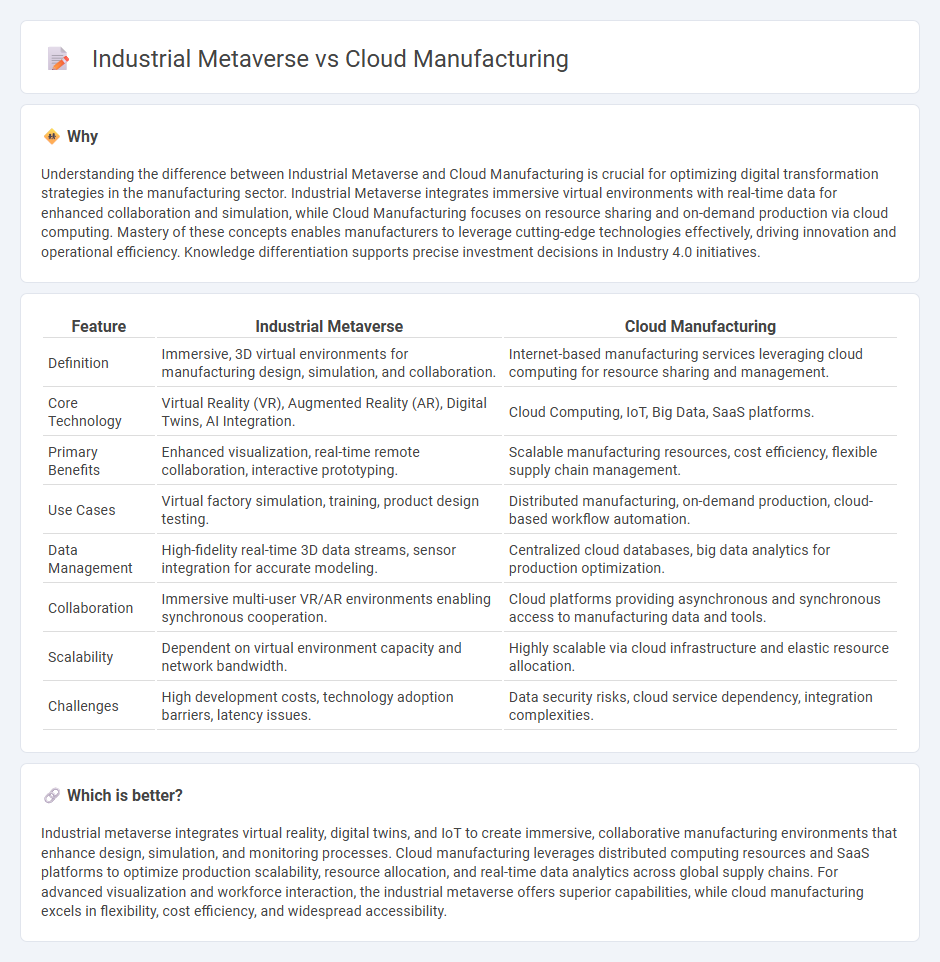

Understanding the difference between Industrial Metaverse and Cloud Manufacturing is crucial for optimizing digital transformation strategies in the manufacturing sector. Industrial Metaverse integrates immersive virtual environments with real-time data for enhanced collaboration and simulation, while Cloud Manufacturing focuses on resource sharing and on-demand production via cloud computing. Mastery of these concepts enables manufacturers to leverage cutting-edge technologies effectively, driving innovation and operational efficiency. Knowledge differentiation supports precise investment decisions in Industry 4.0 initiatives.

Comparison Table

| Feature | Industrial Metaverse | Cloud Manufacturing |

|---|---|---|

| Definition | Immersive, 3D virtual environments for manufacturing design, simulation, and collaboration. | Internet-based manufacturing services leveraging cloud computing for resource sharing and management. |

| Core Technology | Virtual Reality (VR), Augmented Reality (AR), Digital Twins, AI Integration. | Cloud Computing, IoT, Big Data, SaaS platforms. |

| Primary Benefits | Enhanced visualization, real-time remote collaboration, interactive prototyping. | Scalable manufacturing resources, cost efficiency, flexible supply chain management. |

| Use Cases | Virtual factory simulation, training, product design testing. | Distributed manufacturing, on-demand production, cloud-based workflow automation. |

| Data Management | High-fidelity real-time 3D data streams, sensor integration for accurate modeling. | Centralized cloud databases, big data analytics for production optimization. |

| Collaboration | Immersive multi-user VR/AR environments enabling synchronous cooperation. | Cloud platforms providing asynchronous and synchronous access to manufacturing data and tools. |

| Scalability | Dependent on virtual environment capacity and network bandwidth. | Highly scalable via cloud infrastructure and elastic resource allocation. |

| Challenges | High development costs, technology adoption barriers, latency issues. | Data security risks, cloud service dependency, integration complexities. |

Which is better?

Industrial metaverse integrates virtual reality, digital twins, and IoT to create immersive, collaborative manufacturing environments that enhance design, simulation, and monitoring processes. Cloud manufacturing leverages distributed computing resources and SaaS platforms to optimize production scalability, resource allocation, and real-time data analytics across global supply chains. For advanced visualization and workforce interaction, the industrial metaverse offers superior capabilities, while cloud manufacturing excels in flexibility, cost efficiency, and widespread accessibility.

Connection

Industrial metaverse integrates virtual environments with real-time data from IoT devices, enabling immersive simulation and optimization of manufacturing processes. Cloud manufacturing leverages distributed computing resources to provide scalable access to design, production, and management tools via the internet. Their connection enhances collaborative product development, real-time monitoring, and remote operations, driving efficiency and innovation in smart factories.

Key Terms

Resource Virtualization

Cloud manufacturing leverages distributed computing resources to enable real-time resource virtualization, enhancing flexibility and scalability in production processes. The industrial metaverse extends this concept by creating immersive, interconnected digital twins that simulate entire factory ecosystems, providing more dynamic and interactive resource management. Discover how these technologies revolutionize manufacturing efficiency and resource utilization.

Digital Twin

Cloud manufacturing leverages remote data storage and real-time analytics to optimize production processes, enabling seamless integration of digital twins for monitoring and simulation. The industrial metaverse extends these capabilities by creating immersive, interactive virtual environments where digital twins replicate entire factory ecosystems for enhanced collaboration and training. Explore how these technologies converge to transform smart manufacturing and drive Industry 4.0 innovation.

Real-time Collaboration

Cloud Manufacturing enables real-time collaboration through centralized data sharing and seamless integration of IoT devices, enhancing production efficiency and reducing downtime. Industrial metaverse leverages immersive virtual environments for interactive design and simulation, facilitating collaborative problem-solving and remote training in real-time. Explore the differences between these innovative technologies to optimize your industrial collaboration strategy.

Source and External Links

Cloud manufacturing - Wikipedia - Cloud manufacturing is a new paradigm transforming manufacturing resources and capabilities into virtualized, on-demand services enabled by cloud computing, IoT, and advanced computing technologies, covering the entire product lifecycle from design to maintenance.

What is Cloud Manufacturing & How Does It Work? - Cloud manufacturing is a business strategy using cloud-based systems to manage manufacturing operations, increasing efficiency, reducing costs, enabling remote access, and integrating systems for seamless workflow.

What is Microsoft Cloud for Manufacturing? - Microsoft Cloud for Manufacturing enhances digital transformation by integrating cloud computing, AI, and IoT to innovate product design, supply chain resilience, and factory intelligence through interoperable solutions.

dowidth.com

dowidth.com