Lights-out manufacturing utilizes fully automated production systems operating without human intervention, maximizing efficiency and minimizing labor costs. Cellular manufacturing arranges workstations in cells to streamline workflow, enhance flexibility, and improve product quality through human-machine collaboration. Discover how these innovative manufacturing strategies can transform your production process.

Why it is important

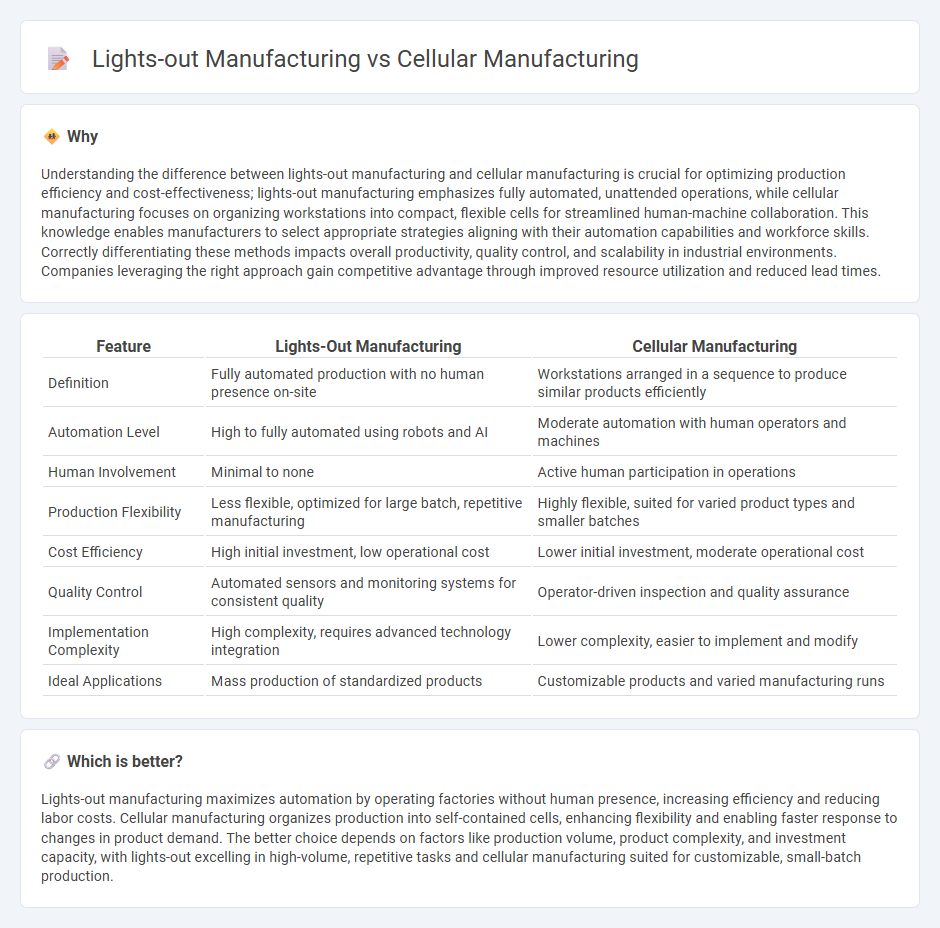

Understanding the difference between lights-out manufacturing and cellular manufacturing is crucial for optimizing production efficiency and cost-effectiveness; lights-out manufacturing emphasizes fully automated, unattended operations, while cellular manufacturing focuses on organizing workstations into compact, flexible cells for streamlined human-machine collaboration. This knowledge enables manufacturers to select appropriate strategies aligning with their automation capabilities and workforce skills. Correctly differentiating these methods impacts overall productivity, quality control, and scalability in industrial environments. Companies leveraging the right approach gain competitive advantage through improved resource utilization and reduced lead times.

Comparison Table

| Feature | Lights-Out Manufacturing | Cellular Manufacturing |

|---|---|---|

| Definition | Fully automated production with no human presence on-site | Workstations arranged in a sequence to produce similar products efficiently |

| Automation Level | High to fully automated using robots and AI | Moderate automation with human operators and machines |

| Human Involvement | Minimal to none | Active human participation in operations |

| Production Flexibility | Less flexible, optimized for large batch, repetitive manufacturing | Highly flexible, suited for varied product types and smaller batches |

| Cost Efficiency | High initial investment, low operational cost | Lower initial investment, moderate operational cost |

| Quality Control | Automated sensors and monitoring systems for consistent quality | Operator-driven inspection and quality assurance |

| Implementation Complexity | High complexity, requires advanced technology integration | Lower complexity, easier to implement and modify |

| Ideal Applications | Mass production of standardized products | Customizable products and varied manufacturing runs |

Which is better?

Lights-out manufacturing maximizes automation by operating factories without human presence, increasing efficiency and reducing labor costs. Cellular manufacturing organizes production into self-contained cells, enhancing flexibility and enabling faster response to changes in product demand. The better choice depends on factors like production volume, product complexity, and investment capacity, with lights-out excelling in high-volume, repetitive tasks and cellular manufacturing suited for customizable, small-batch production.

Connection

Lights-out manufacturing relies on automation and robotics to operate factories with minimal human intervention, aligning closely with the principles of cellular manufacturing, which organizes equipment into optimized, self-contained cells to enhance efficiency. Cellular manufacturing supports the streamlined processes required for lights-out operations by reducing setup times and enabling flexible, continuous production flows. The integration of these two methodologies significantly boosts productivity and lowers operational costs in advanced manufacturing environments.

Key Terms

**Cellular Manufacturing:**

Cellular manufacturing organizes workstations into small, manageable cells to enhance efficiency and reduce waste by enabling smoother workflow and quicker response times. It emphasizes human involvement and flexibility, facilitating quality control and continuous improvement through operator skill development. Explore how cellular manufacturing can transform your production process with adaptive strategies and improved team collaboration.

Work Cells

Cellular manufacturing organizes work cells to optimize workflow by grouping machines and operators around specific product families, enhancing efficiency and reducing waste. Lights-out manufacturing employs automated work cells that operate without human intervention, using robotics and AI to maintain continuous production. Explore how integrating work cells in both systems can maximize productivity and operational flexibility.

Lean Production

Cellular manufacturing organizes workstations into small, self-contained units to streamline workflow, reduce waste, and improve efficiency aligned with Lean Production principles. Lights-out manufacturing leverages automation and robotics to operate factories with minimal or no human intervention, enhancing productivity and reducing operational costs. Explore the advantages and implementation strategies of both approaches to optimize your Lean manufacturing system.

Source and External Links

Cellular Manufacturing: A Comprehensive Guide - Deskera - Cellular manufacturing is a production system that combines multiple processes of a production line into a single, unified manufacturing cell, optimizing layout, resource assignment, and process flow to enhance efficiency and responsiveness.

Cellular manufacturing - Wikipedia - Cellular manufacturing is a form of lean manufacturing that consolidates processes into multi-machine cells arranged often in U-shape, enabling flexible, rapid production with minimal waste, improved quality, and reduced lead time.

What Is Cellular Manufacturing? - MRPeasy - It is a production organization method that arranges workstations and equipment into self-sufficient cells designed for continuous flow, improving shop floor communication, shortening lead times, and reducing waste and work-in-process inventory.

dowidth.com

dowidth.com