Industrial Internet integrates advanced sensors, cloud computing, and big data analytics to optimize manufacturing processes by enabling real-time monitoring and predictive maintenance. Cyber-Physical Systems (CPS) combine physical machinery with embedded software to create automated, self-regulating production environments that enhance efficiency and flexibility. Explore the key differences and applications of Industrial Internet and Cyber-Physical Systems to transform modern manufacturing.

Why it is important

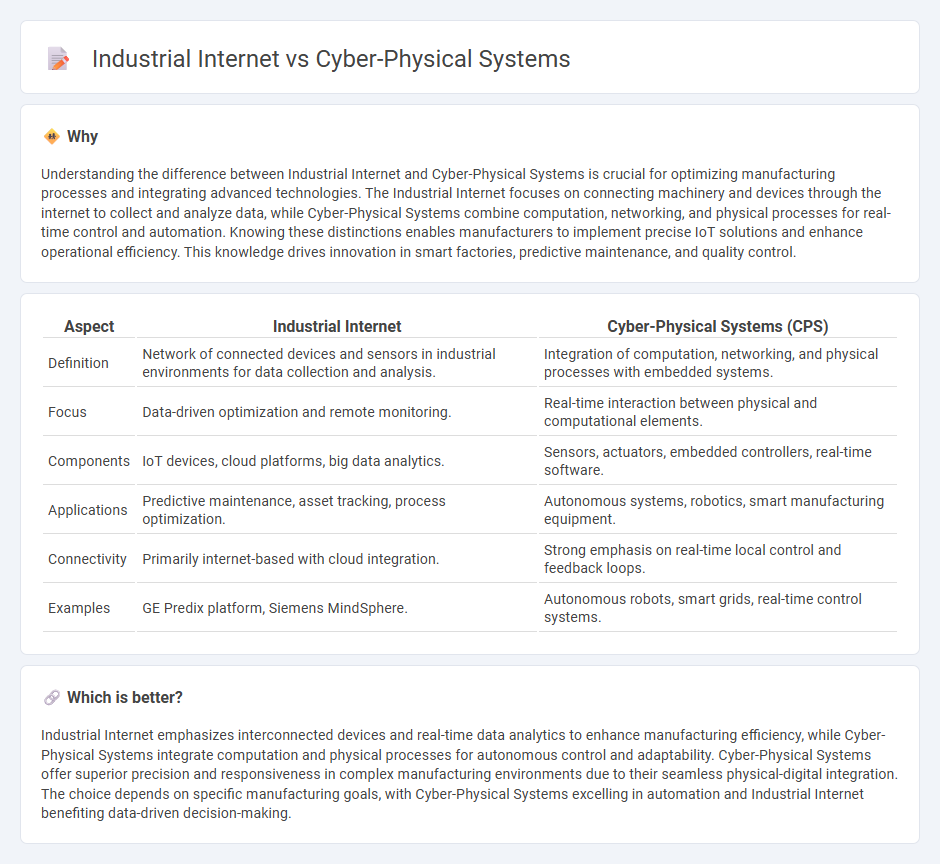

Understanding the difference between Industrial Internet and Cyber-Physical Systems is crucial for optimizing manufacturing processes and integrating advanced technologies. The Industrial Internet focuses on connecting machinery and devices through the internet to collect and analyze data, while Cyber-Physical Systems combine computation, networking, and physical processes for real-time control and automation. Knowing these distinctions enables manufacturers to implement precise IoT solutions and enhance operational efficiency. This knowledge drives innovation in smart factories, predictive maintenance, and quality control.

Comparison Table

| Aspect | Industrial Internet | Cyber-Physical Systems (CPS) |

|---|---|---|

| Definition | Network of connected devices and sensors in industrial environments for data collection and analysis. | Integration of computation, networking, and physical processes with embedded systems. |

| Focus | Data-driven optimization and remote monitoring. | Real-time interaction between physical and computational elements. |

| Components | IoT devices, cloud platforms, big data analytics. | Sensors, actuators, embedded controllers, real-time software. |

| Applications | Predictive maintenance, asset tracking, process optimization. | Autonomous systems, robotics, smart manufacturing equipment. |

| Connectivity | Primarily internet-based with cloud integration. | Strong emphasis on real-time local control and feedback loops. |

| Examples | GE Predix platform, Siemens MindSphere. | Autonomous robots, smart grids, real-time control systems. |

Which is better?

Industrial Internet emphasizes interconnected devices and real-time data analytics to enhance manufacturing efficiency, while Cyber-Physical Systems integrate computation and physical processes for autonomous control and adaptability. Cyber-Physical Systems offer superior precision and responsiveness in complex manufacturing environments due to their seamless physical-digital integration. The choice depends on specific manufacturing goals, with Cyber-Physical Systems excelling in automation and Industrial Internet benefiting data-driven decision-making.

Connection

Industrial Internet integrates sensors, machines, and data analytics to enhance manufacturing operations, while Cyber-Physical Systems (CPS) enable real-time interaction between physical processes and computational models. Both technologies leverage IoT connectivity to optimize production efficiency, reduce downtime, and predict maintenance needs through continuous monitoring. The synergy of Industrial Internet and CPS drives smart factories by enabling autonomous decision-making and adaptive control in complex manufacturing environments.

Key Terms

Integration

Cyber-Physical Systems (CPS) integrate computational algorithms with physical processes through embedded computers and networks, enabling real-time monitoring and control in industrial environments. The Industrial Internet emphasizes connectivity between industrial machines, analytics, and people to improve operational efficiency via big data and cloud computing integration. Explore how these technologies converge to redefine smart manufacturing and industrial automation.

Connectivity

Cyber-Physical Systems integrate computation, networking, and physical processes to enable real-time data exchange and precise control through embedded sensors and actuators. The Industrial Internet emphasizes large-scale connectivity among industrial devices using IoT technologies to optimize operations, enhance automation, and improve predictive maintenance. Discover how these connectivity frameworks revolutionize industry efficiency and innovation.

Data Analytics

Cyber-Physical Systems (CPS) integrate computational algorithms with physical processes to enable real-time data collection and automated decision-making, while the Industrial Internet emphasizes interconnected industrial devices and systems for enhanced operational efficiency. Data analytics in CPS leverages sensor data and machine learning models to predict system behavior and optimize performance, whereas the Industrial Internet utilizes big data analytics and cloud computing to monitor assets and improve predictive maintenance. Explore the latest advancements in data analytics within these domains to enhance industrial innovation and operational intelligence.

Source and External Links

Cyber-Physical Systems (CPS) Explained - Splunk - Cyber-Physical Systems integrate sensing, computation, control, and networking into physical objects and infrastructure, enabling digital modeling and centralized control of complex physical processes and driving advancements in Industry 4.0.

Cyber-Physical Systems - a Concept Map - Ptolemy Project - CPS are engineered integrations of computation, networking, and physical processes with feedback loops, combining mathematical abstractions from physical science and computer science to model dynamic systems in real time.

10 Examples of Cyber-Physical Systems | Claroty - Cyber-Physical Systems are platforms that merge computation, control, and networking tightly with physical processes, found in critical industries like manufacturing and healthcare and requiring specialized cybersecurity due to their impact on physical safety.

dowidth.com

dowidth.com