Human augmentation in manufacturing enhances worker capabilities through wearable devices and implanted technologies, boosting productivity and safety. Smart sensors provide real-time data collection and machine monitoring, enabling predictive maintenance and process optimization. Explore how these innovations transform industrial efficiency and workforce dynamics.

Why it is important

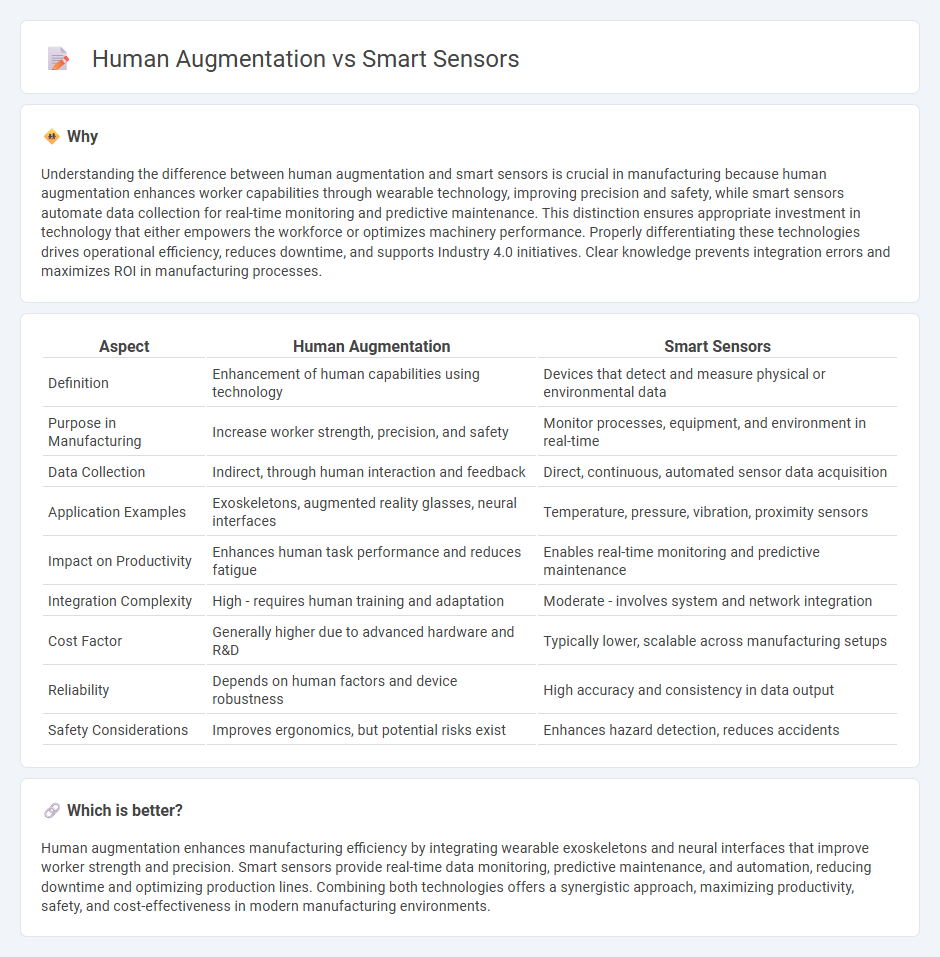

Understanding the difference between human augmentation and smart sensors is crucial in manufacturing because human augmentation enhances worker capabilities through wearable technology, improving precision and safety, while smart sensors automate data collection for real-time monitoring and predictive maintenance. This distinction ensures appropriate investment in technology that either empowers the workforce or optimizes machinery performance. Properly differentiating these technologies drives operational efficiency, reduces downtime, and supports Industry 4.0 initiatives. Clear knowledge prevents integration errors and maximizes ROI in manufacturing processes.

Comparison Table

| Aspect | Human Augmentation | Smart Sensors |

|---|---|---|

| Definition | Enhancement of human capabilities using technology | Devices that detect and measure physical or environmental data |

| Purpose in Manufacturing | Increase worker strength, precision, and safety | Monitor processes, equipment, and environment in real-time |

| Data Collection | Indirect, through human interaction and feedback | Direct, continuous, automated sensor data acquisition |

| Application Examples | Exoskeletons, augmented reality glasses, neural interfaces | Temperature, pressure, vibration, proximity sensors |

| Impact on Productivity | Enhances human task performance and reduces fatigue | Enables real-time monitoring and predictive maintenance |

| Integration Complexity | High - requires human training and adaptation | Moderate - involves system and network integration |

| Cost Factor | Generally higher due to advanced hardware and R&D | Typically lower, scalable across manufacturing setups |

| Reliability | Depends on human factors and device robustness | High accuracy and consistency in data output |

| Safety Considerations | Improves ergonomics, but potential risks exist | Enhances hazard detection, reduces accidents |

Which is better?

Human augmentation enhances manufacturing efficiency by integrating wearable exoskeletons and neural interfaces that improve worker strength and precision. Smart sensors provide real-time data monitoring, predictive maintenance, and automation, reducing downtime and optimizing production lines. Combining both technologies offers a synergistic approach, maximizing productivity, safety, and cost-effectiveness in modern manufacturing environments.

Connection

Human augmentation in manufacturing leverages smart sensors to enhance worker capabilities by providing real-time data on physical movements and environmental conditions. These sensors enable precision monitoring, improving safety and efficiency on the factory floor by detecting fatigue, posture, and exposure to hazardous substances. Integrating smart sensor technology with wearable augmentations optimizes human performance, reduces error rates, and supports predictive maintenance in industrial processes.

Key Terms

**Smart Sensors:**

Smart sensors integrate advanced technologies such as IoT connectivity, AI algorithms, and real-time data processing to enhance accuracy and efficiency in various applications, ranging from industrial automation to healthcare monitoring. These devices offer seamless environmental awareness and predictive capabilities, enabling proactive decision-making and improved system performance without direct human intervention. Explore the innovations driving smart sensors to revolutionize industries and everyday life.

IoT Integration

Smart sensors play a crucial role in IoT integration by providing real-time data collection and analysis, enabling enhanced automation and predictive maintenance across smart environments. Human augmentation, leveraging IoT-enabled wearable devices, enhances cognitive and physical abilities by seamlessly interacting with interconnected systems for personalized health monitoring and augmented reality experiences. Explore the evolving impact of smart sensors and human augmentation on IoT to unlock the future of connected intelligence.

Real-time Data Acquisition

Smart sensors enable precise real-time data acquisition by continuously monitoring environmental and physiological parameters with high accuracy and low latency, surpassing manual human observation limitations. Human augmentation integrates smart sensors within wearable or implantable devices, enhancing users' sensory and cognitive abilities through instant processing and feedback, thus bridging the gap between raw data and actionable insights. Explore how advancements in smart sensor technology and human augmentation are revolutionizing real-time data acquisition for various industries.

Source and External Links

Smart sensors: What are they? How do they work? - DataScientest - Smart sensors are advanced devices that not only collect data from the physical environment but also process it on-site using embedded computing, enabling real-time, precise, and automated insights for improved decision-making.

What is a Smart Sensor and How Does it Work? - TechTarget - A smart sensor combines a base sensing element with integrated computing and communication capabilities, allowing it to process, filter, and transmit data digitally for applications in industrial automation, security, and process control.

Intelligent sensor - Wikipedia - An intelligent sensor is a device that senses specific physical inputs, processes the data internally using a microprocessor, and can communicate the results digitally, distinguishing it from traditional sensors that only detect and transmit raw signals.

dowidth.com

dowidth.com