Lattice structure design in manufacturing offers enhanced strength-to-weight ratios and improved material efficiency by utilizing interconnected geometric patterns, while framework structure design focuses on rigid support systems composed of beams and columns for load distribution. Lattice designs excel in lightweight applications such as aerospace and automotive industries, whereas framework structures are prevalent in construction and heavy machinery due to their stability and ease of assembly. Discover more about how these design methodologies transform manufacturing processes and product performance.

Why it is important

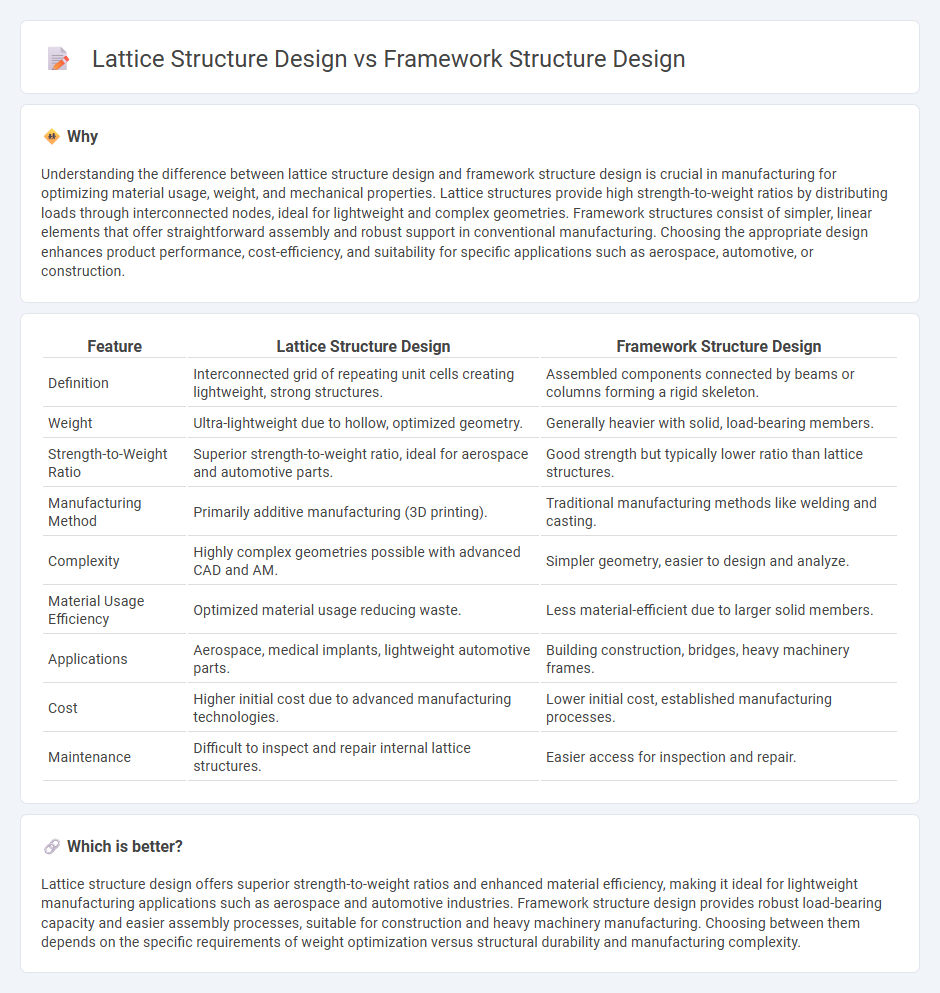

Understanding the difference between lattice structure design and framework structure design is crucial in manufacturing for optimizing material usage, weight, and mechanical properties. Lattice structures provide high strength-to-weight ratios by distributing loads through interconnected nodes, ideal for lightweight and complex geometries. Framework structures consist of simpler, linear elements that offer straightforward assembly and robust support in conventional manufacturing. Choosing the appropriate design enhances product performance, cost-efficiency, and suitability for specific applications such as aerospace, automotive, or construction.

Comparison Table

| Feature | Lattice Structure Design | Framework Structure Design |

|---|---|---|

| Definition | Interconnected grid of repeating unit cells creating lightweight, strong structures. | Assembled components connected by beams or columns forming a rigid skeleton. |

| Weight | Ultra-lightweight due to hollow, optimized geometry. | Generally heavier with solid, load-bearing members. |

| Strength-to-Weight Ratio | Superior strength-to-weight ratio, ideal for aerospace and automotive parts. | Good strength but typically lower ratio than lattice structures. |

| Manufacturing Method | Primarily additive manufacturing (3D printing). | Traditional manufacturing methods like welding and casting. |

| Complexity | Highly complex geometries possible with advanced CAD and AM. | Simpler geometry, easier to design and analyze. |

| Material Usage Efficiency | Optimized material usage reducing waste. | Less material-efficient due to larger solid members. |

| Applications | Aerospace, medical implants, lightweight automotive parts. | Building construction, bridges, heavy machinery frames. |

| Cost | Higher initial cost due to advanced manufacturing technologies. | Lower initial cost, established manufacturing processes. |

| Maintenance | Difficult to inspect and repair internal lattice structures. | Easier access for inspection and repair. |

Which is better?

Lattice structure design offers superior strength-to-weight ratios and enhanced material efficiency, making it ideal for lightweight manufacturing applications such as aerospace and automotive industries. Framework structure design provides robust load-bearing capacity and easier assembly processes, suitable for construction and heavy machinery manufacturing. Choosing between them depends on the specific requirements of weight optimization versus structural durability and manufacturing complexity.

Connection

Lattice structure design enhances manufacturing efficiency by optimizing material distribution within framework structure design, resulting in lightweight yet strong components. Integrating lattice designs into framework structures improves load-bearing capacity while reducing weight, crucial for aerospace and automotive industries. Advanced CAD and additive manufacturing technologies enable precise implementation of complex lattice geometries within traditional framework designs, driving innovation in product performance and material savings.

Key Terms

Load Distribution

Framework structure design distributes loads through interconnected beams and columns, effectively managing vertical and horizontal forces by creating a stable skeleton that supports applied stresses. Lattice structure design utilizes a network of interwoven elements to disperse loads evenly, enhancing strength-to-weight ratio by transferring forces along multiple pathways. Explore detailed comparisons to understand which design optimally suits specific engineering applications.

Material Efficiency

Framework structure design maximizes material efficiency by using strategically placed members to bear loads while minimizing weight and material usage. Lattice structure design achieves high strength-to-weight ratios through repetitive, interconnected triangular units that distribute stress evenly across the structure. Explore more to understand how each design optimizes material efficiency for different engineering applications.

Geometric Complexity

Framework structure design emphasizes simplified geometric forms with clear load paths, optimizing for ease of fabrication and efficient material usage. Lattice structure design incorporates highly intricate geometries and repetitive unit cells to achieve superior strength-to-weight ratios and enhanced mechanical properties. Explore further to understand how geometric complexity influences structural performance and application suitability.

Source and External Links

How to Build an Effective Design Framework | Toptal(r) - A design framework starts by establishing a strong visual hierarchy, beginning with foundational elements like color and typography, followed by smaller components, and includes setting up grids to organize the design space effectively.

Design frameworks: what are they and why you should be using them - Design frameworks help structure problem-solving by providing core principles and a flexible structure that guides the creation of design solutions aligned to user and business needs.

How to Make a Design Framework to Structure Your Project - A design framework is a visual structure made from categories developed through research, helping organize information and focus ideation based on real user or project needs.

dowidth.com

dowidth.com