Machine vision systems offer faster and more consistent inspection results compared to human inspectors, significantly reducing error rates and improving production efficiency. Advanced algorithms and high-resolution cameras enable detection of minute defects that are often missed by the human eye, enhancing quality control in manufacturing processes. Explore the evolving role of machine vision and human inspection to optimize manufacturing outcomes.

Why it is important

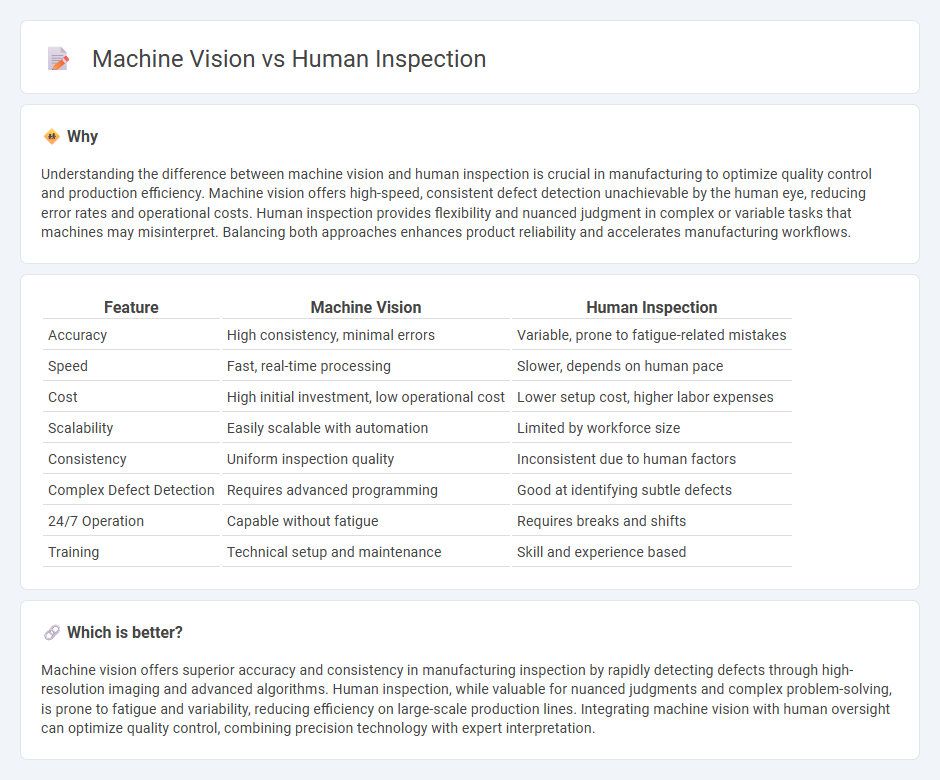

Understanding the difference between machine vision and human inspection is crucial in manufacturing to optimize quality control and production efficiency. Machine vision offers high-speed, consistent defect detection unachievable by the human eye, reducing error rates and operational costs. Human inspection provides flexibility and nuanced judgment in complex or variable tasks that machines may misinterpret. Balancing both approaches enhances product reliability and accelerates manufacturing workflows.

Comparison Table

| Feature | Machine Vision | Human Inspection |

|---|---|---|

| Accuracy | High consistency, minimal errors | Variable, prone to fatigue-related mistakes |

| Speed | Fast, real-time processing | Slower, depends on human pace |

| Cost | High initial investment, low operational cost | Lower setup cost, higher labor expenses |

| Scalability | Easily scalable with automation | Limited by workforce size |

| Consistency | Uniform inspection quality | Inconsistent due to human factors |

| Complex Defect Detection | Requires advanced programming | Good at identifying subtle defects |

| 24/7 Operation | Capable without fatigue | Requires breaks and shifts |

| Training | Technical setup and maintenance | Skill and experience based |

Which is better?

Machine vision offers superior accuracy and consistency in manufacturing inspection by rapidly detecting defects through high-resolution imaging and advanced algorithms. Human inspection, while valuable for nuanced judgments and complex problem-solving, is prone to fatigue and variability, reducing efficiency on large-scale production lines. Integrating machine vision with human oversight can optimize quality control, combining precision technology with expert interpretation.

Connection

Machine vision enhances manufacturing quality control by providing precise, automated defect detection and measurement, reducing human error and increasing inspection speed. Human inspection complements machine vision by applying expert judgment and handling complex evaluations that require cognitive interpretation or nuanced decision-making. Integrating machine vision systems with skilled human inspectors leads to higher accuracy, improved efficiency, and consistent product quality in manufacturing processes.

Key Terms

Accuracy

Human inspection provides flexible evaluation but often suffers from inconsistency and fatigue, leading to variable accuracy rates. Machine vision systems utilize advanced algorithms and high-resolution cameras to achieve consistent accuracy levels of over 99% in defect detection and quality control. Explore how integrating machine vision can elevate precision in your inspection processes.

Consistency

Human inspection often faces challenges with consistency due to fatigue and subjective judgment, leading to variability in quality control processes. Machine vision systems deliver high consistency by leveraging advanced algorithms and real-time data analysis to detect defects with precise accuracy across large production volumes. Discover how integrating machine vision can revolutionize your quality assurance strategy for unparalleled consistency.

Subjectivity

Human inspection relies on subjective judgment influenced by experience, perception, and individual biases, which can lead to inconsistencies in quality assessment. Machine vision employs objective algorithms and sensors to analyze visual data with high precision and repeatability, minimizing errors caused by human subjectivity. Discover how integrating machine vision systems can enhance inspection accuracy and reduce subjectivity in quality control processes.

Source and External Links

Balancing Act: Human vs. Machine Inspection in Pharmaceutical Manufacturing - This article discusses the role of human inspectors in pharmaceuticals, highlighting their adaptability and limitations compared to automated systems.

Sound Practices for Consistent Human Visual Inspection - This document outlines essential requirements for conducting manual inspections, emphasizing the importance of inspector qualification, including eye exams and training.

What Is Visual Inspection? - Visual inspection involves using the naked eye or digital images to detect defects in equipment or products, highlighting its effectiveness in various industries.

dowidth.com

dowidth.com