Automated guided vehicles (AGVs) enhance manufacturing efficiency by autonomously transporting materials across factory floors with precision, reducing labor costs and minimizing errors. Automated storage and retrieval systems (AS/RS) optimize warehouse operations by using robotic technology to store and retrieve inventory rapidly, improving space utilization and inventory accuracy. Explore how integrating AGVs and AS/RS can revolutionize your manufacturing workflow and boost productivity.

Why it is important

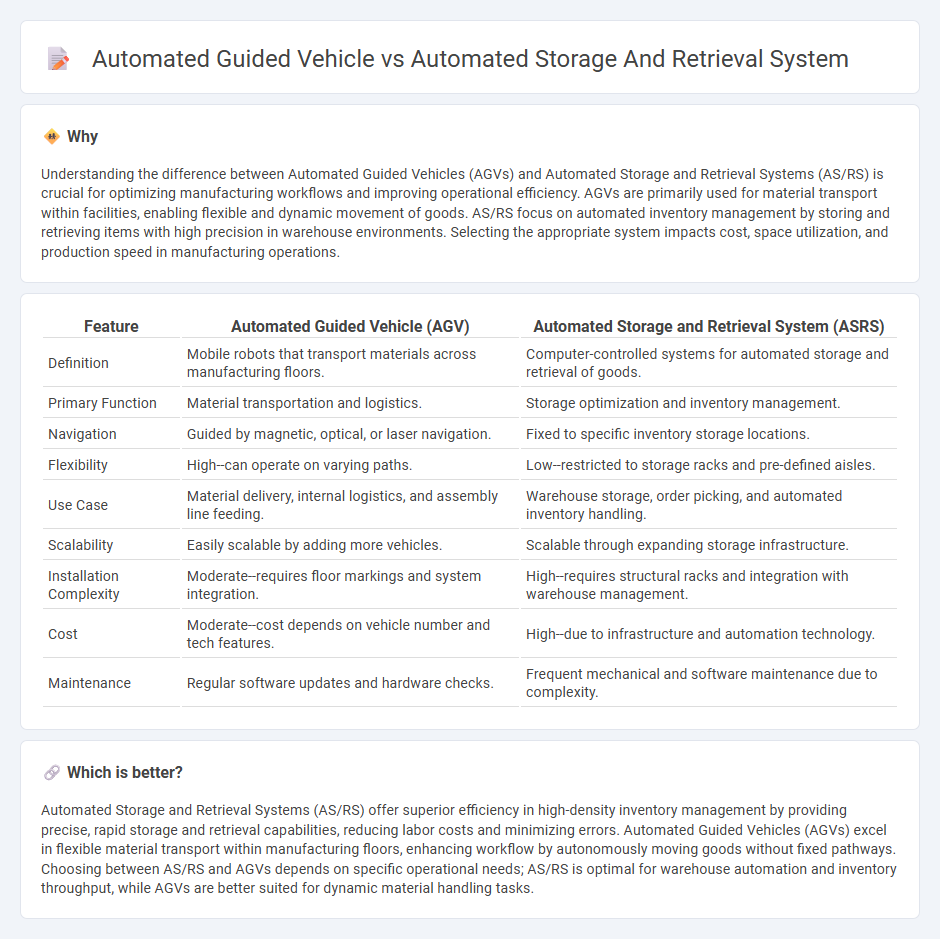

Understanding the difference between Automated Guided Vehicles (AGVs) and Automated Storage and Retrieval Systems (AS/RS) is crucial for optimizing manufacturing workflows and improving operational efficiency. AGVs are primarily used for material transport within facilities, enabling flexible and dynamic movement of goods. AS/RS focus on automated inventory management by storing and retrieving items with high precision in warehouse environments. Selecting the appropriate system impacts cost, space utilization, and production speed in manufacturing operations.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Automated Storage and Retrieval System (ASRS) |

|---|---|---|

| Definition | Mobile robots that transport materials across manufacturing floors. | Computer-controlled systems for automated storage and retrieval of goods. |

| Primary Function | Material transportation and logistics. | Storage optimization and inventory management. |

| Navigation | Guided by magnetic, optical, or laser navigation. | Fixed to specific inventory storage locations. |

| Flexibility | High--can operate on varying paths. | Low--restricted to storage racks and pre-defined aisles. |

| Use Case | Material delivery, internal logistics, and assembly line feeding. | Warehouse storage, order picking, and automated inventory handling. |

| Scalability | Easily scalable by adding more vehicles. | Scalable through expanding storage infrastructure. |

| Installation Complexity | Moderate--requires floor markings and system integration. | High--requires structural racks and integration with warehouse management. |

| Cost | Moderate--cost depends on vehicle number and tech features. | High--due to infrastructure and automation technology. |

| Maintenance | Regular software updates and hardware checks. | Frequent mechanical and software maintenance due to complexity. |

Which is better?

Automated Storage and Retrieval Systems (AS/RS) offer superior efficiency in high-density inventory management by providing precise, rapid storage and retrieval capabilities, reducing labor costs and minimizing errors. Automated Guided Vehicles (AGVs) excel in flexible material transport within manufacturing floors, enhancing workflow by autonomously moving goods without fixed pathways. Choosing between AS/RS and AGVs depends on specific operational needs; AS/RS is optimal for warehouse automation and inventory throughput, while AGVs are better suited for dynamic material handling tasks.

Connection

Automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS) are interconnected components within modern manufacturing logistics, where AGVs transport materials between production lines and AS/RS units efficiently manage inventory storage and retrieval. Integration of AGVs with AS/RS optimizes workflow by reducing manual handling, enhancing accuracy in inventory placement, and accelerating material flow through real-time coordination. This synergy improves overall manufacturing productivity, minimizes errors, and supports just-in-time production strategies.

Key Terms

**Automated storage and retrieval system (AS/RS):**

Automated storage and retrieval systems (AS/RS) enhance warehouse efficiency by utilizing automated machinery to store and retrieve inventory with high precision and speed, significantly reducing labor costs and errors. These systems are ideal for environments requiring high-density storage and inventory accuracy due to their integration with warehouse management software and real-time data tracking. Discover how AS/RS technology can transform inventory management and streamline your supply chain operations.

Rack Structure

Automated storage and retrieval systems (AS/RS) rely on fixed rack structures designed for high-density storage and precise inventory management, enabling efficient vertical stacking and retrieval of goods within warehouses. In contrast, automated guided vehicles (AGVs) do not depend on rigid rack setups but navigate flexible pathways, making them suitable for dynamic environments with varying storage configurations. Explore more to understand how rack design impacts operational efficiency in AS/RS and AGV implementations.

Shuttle/Crane

Automated storage and retrieval systems (AS/RS) utilize shuttles and cranes to efficiently store and retrieve goods in warehouses, offering precise inventory control and high-density storage. Automated guided vehicles (AGVs) differ by providing flexible material transport across various locations without fixed infrastructure. Explore further to understand how each solution can optimize your warehouse operations.

Source and External Links

Automated storage and retrieval system - An automated storage and retrieval system (ASRS) is a computer-controlled system for automatically placing and retrieving loads from defined storage locations, often used where high storage density is crucial.

The Ultimate Guide to ASRS - This guide provides an overview of ASRS, highlighting its benefits in efficient warehouse space use, high accuracy, and productivity, as well as addressing labor challenges and providing better stock management.

Automated Storage & Retrieval Systems (AS/RS) - ASRS systems improve throughput and efficiency by offering reliable, secure storage that reduces damage to products and equipment, while providing safer and more ergonomic working conditions.

dowidth.com

dowidth.com