Additive manufacturing and extrusion are pivotal techniques in modern manufacturing processes, each offering unique advantages for fabricating complex parts. Additive manufacturing builds objects layer by layer via methods like selective laser sintering and stereolithography, enabling high precision and customization. Explore the differences between these methods to enhance your manufacturing strategy.

Why it is important

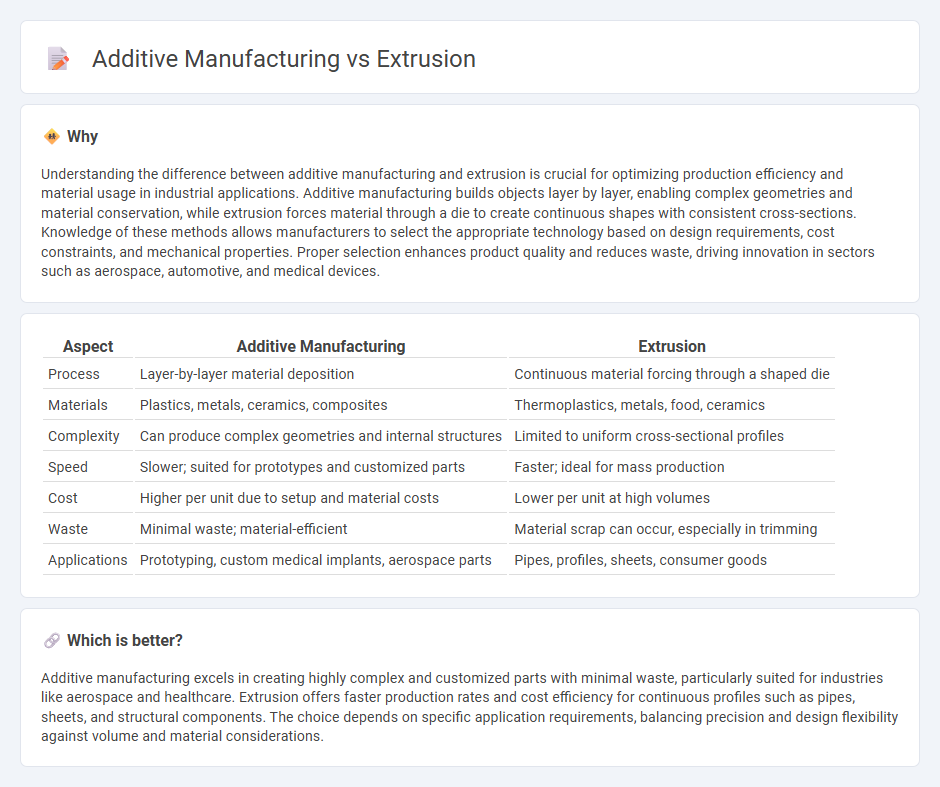

Understanding the difference between additive manufacturing and extrusion is crucial for optimizing production efficiency and material usage in industrial applications. Additive manufacturing builds objects layer by layer, enabling complex geometries and material conservation, while extrusion forces material through a die to create continuous shapes with consistent cross-sections. Knowledge of these methods allows manufacturers to select the appropriate technology based on design requirements, cost constraints, and mechanical properties. Proper selection enhances product quality and reduces waste, driving innovation in sectors such as aerospace, automotive, and medical devices.

Comparison Table

| Aspect | Additive Manufacturing | Extrusion |

|---|---|---|

| Process | Layer-by-layer material deposition | Continuous material forcing through a shaped die |

| Materials | Plastics, metals, ceramics, composites | Thermoplastics, metals, food, ceramics |

| Complexity | Can produce complex geometries and internal structures | Limited to uniform cross-sectional profiles |

| Speed | Slower; suited for prototypes and customized parts | Faster; ideal for mass production |

| Cost | Higher per unit due to setup and material costs | Lower per unit at high volumes |

| Waste | Minimal waste; material-efficient | Material scrap can occur, especially in trimming |

| Applications | Prototyping, custom medical implants, aerospace parts | Pipes, profiles, sheets, consumer goods |

Which is better?

Additive manufacturing excels in creating highly complex and customized parts with minimal waste, particularly suited for industries like aerospace and healthcare. Extrusion offers faster production rates and cost efficiency for continuous profiles such as pipes, sheets, and structural components. The choice depends on specific application requirements, balancing precision and design flexibility against volume and material considerations.

Connection

Additive manufacturing and extrusion are interconnected through their use of precise layer-by-layer material deposition to create complex objects. Extrusion serves as a primary method in additive manufacturing, pushing thermoplastic or metal materials through a nozzle to build parts with minimal waste. This synergy enhances production efficiency and enables rapid prototyping across automotive, aerospace, and biomedical industries.

Key Terms

Material Flow

Extrusion involves continuous material flow through a die to create objects with uniform cross-sections, using thermoplastic or metal feedstock melted and forced out steadily. Additive manufacturing, particularly fused deposition modeling (FDM), deposits material layer by layer, controlling flow rate and cooling to build complex geometries with precise material placement. Explore detailed comparisons of material flow dynamics in extrusion and additive manufacturing to optimize process selection and product design.

Layer-by-Layer

Extrusion manufacturing involves depositing molten material through a nozzle to build layers, commonly used in plastic and metal parts production, while additive manufacturing encompasses various techniques like stereolithography and selective laser sintering that form objects by sequentially adding material. Layer-by-layer construction in extrusion provides precise control over material flow but is often limited by surface finish and geometric complexity compared to other additive methods. Explore the nuances of layer-by-layer processes in extrusion and additive manufacturing for insights into selecting the optimal fabrication technique.

Die/Forming

Extrusion involves forcing material through a shaped die to create continuous profiles with uniform cross-sections, ideal for metals, plastics, and ceramics. Additive manufacturing, specifically in die/forming, builds objects layer-by-layer using digital models, enabling complex geometries without the need for traditional dies. Explore detailed comparisons of extrusion and additive manufacturing techniques to optimize your manufacturing processes.

Source and External Links

Understanding Extrusion: A Fundamental Manufacturing Process - Extrusion is a manufacturing method where raw material is heated and forced through a shaped die to create objects with a fixed cross-sectional profile, including variants like direct, indirect, cold, and hot extrusion based on temperature and process mechanics.

Extrusion - Wikipedia - Extrusion creates objects with a fixed cross-section by pushing material through a die, allowing complex shapes, working with brittle materials, and can be done continuously or semi-continuously with metals, polymers, ceramics, and more.

Metal Extrusion Services | Quality Extruded Parts - Xometry - Metal extrusion typically uses direct extrusion, pushing a billet through a die, or indirect extrusion, where the die moves with the ram, each with advantages related to friction, heat generation, control over material properties, and die size limitations.

dowidth.com

dowidth.com